Permanent magnetic synchronous arm rest lift traction machine

A technology of synchronous escalator traction machine and permanent magnet synchronous motor, which is applied in the field of traction machines, can solve the problems of difficulty in guaranteeing the mechanical and electrical properties of products, inability to achieve organic integration, and reduction in efficiency, saving excitation current, The effect of improved efficiency and high motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

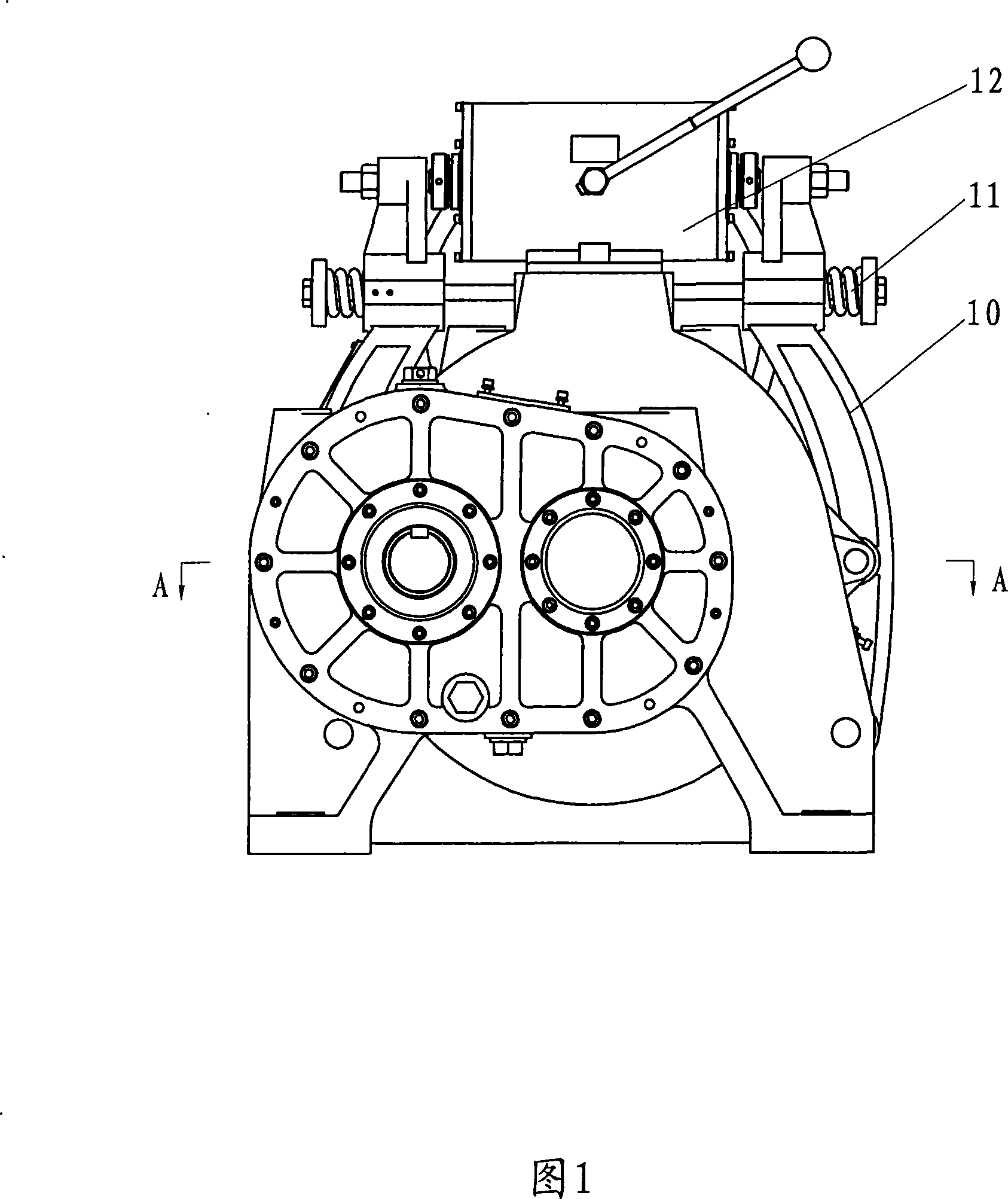

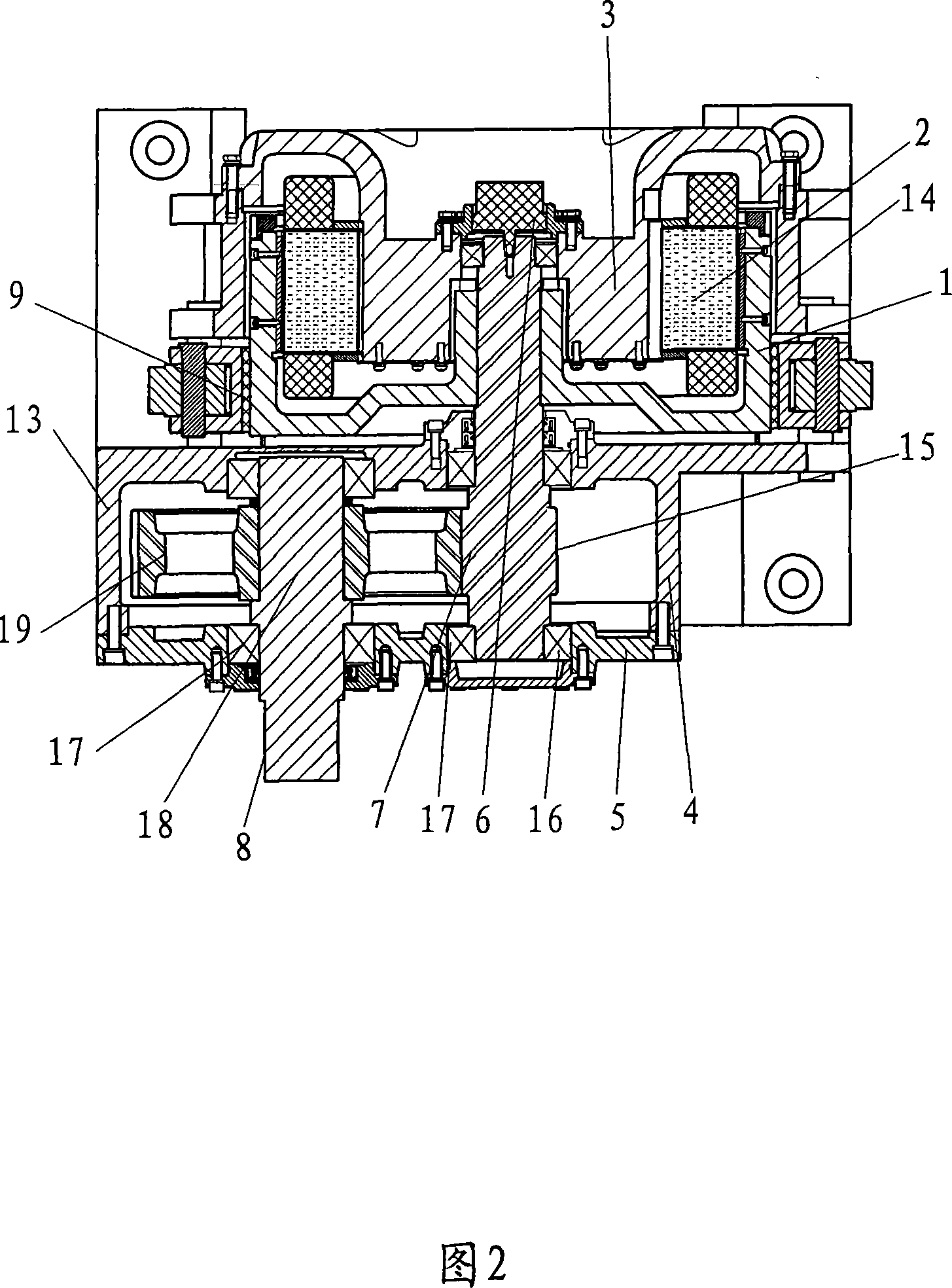

[0010] In the present invention, the prime mover is a permanent magnet synchronous motor using permanent magnet synchronous technology, and the output of the permanent magnet synchronous motor is converted into the output of the escalator traction machine through the reduction mechanism.

[0011] Specific embodiments of the present invention are described as follows: We can see from the figure that the traction machine base 13 is divided into two parts, the front and the back, and the rear part is used as the casing 14 of the permanent magnet synchronous motor. Cover 3 is connected thereto. Inside the casing, the outside of the motor stator 2 is the motor rotor 1, which is rigidly connected to the high-speed gear shaft (motor shaft) 7, and the motor rotor 1 is fixed inside the motor casing through the bearings 16 at both ends of the high-speed gear shaft, and Can rotate around the motor stator 2. The front part of the traction machine base 13 is a gear reduction box 4, the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com