Design of settlement joint provided inside underground continuous wall and construction method thereof

A technology for underground diaphragm walls and settlement joints, applied to artificial islands, water conservancy projects, underwater structures, etc., can solve problems such as long construction period, achieve convenient construction, avoid water seepage, and shorten construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

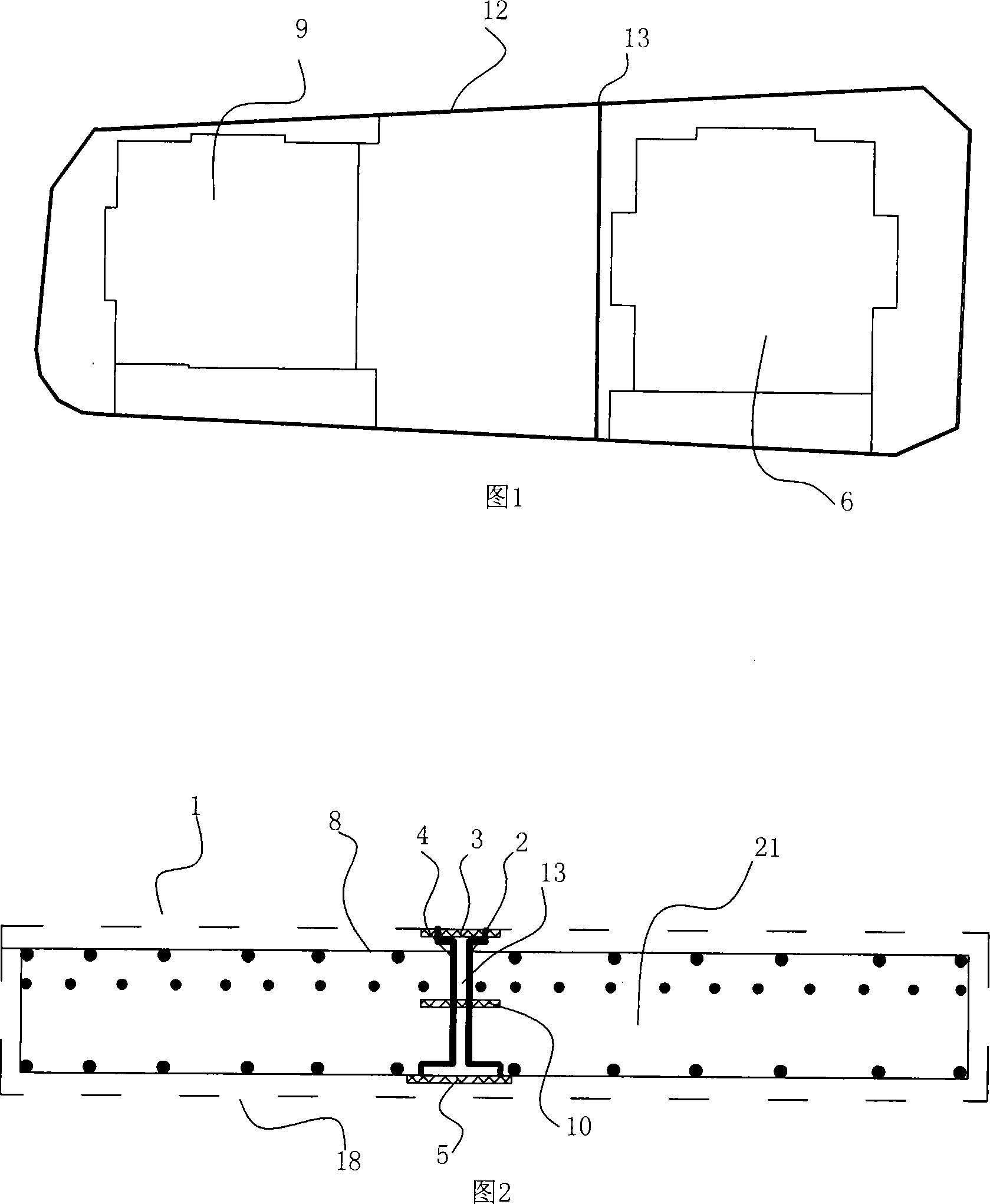

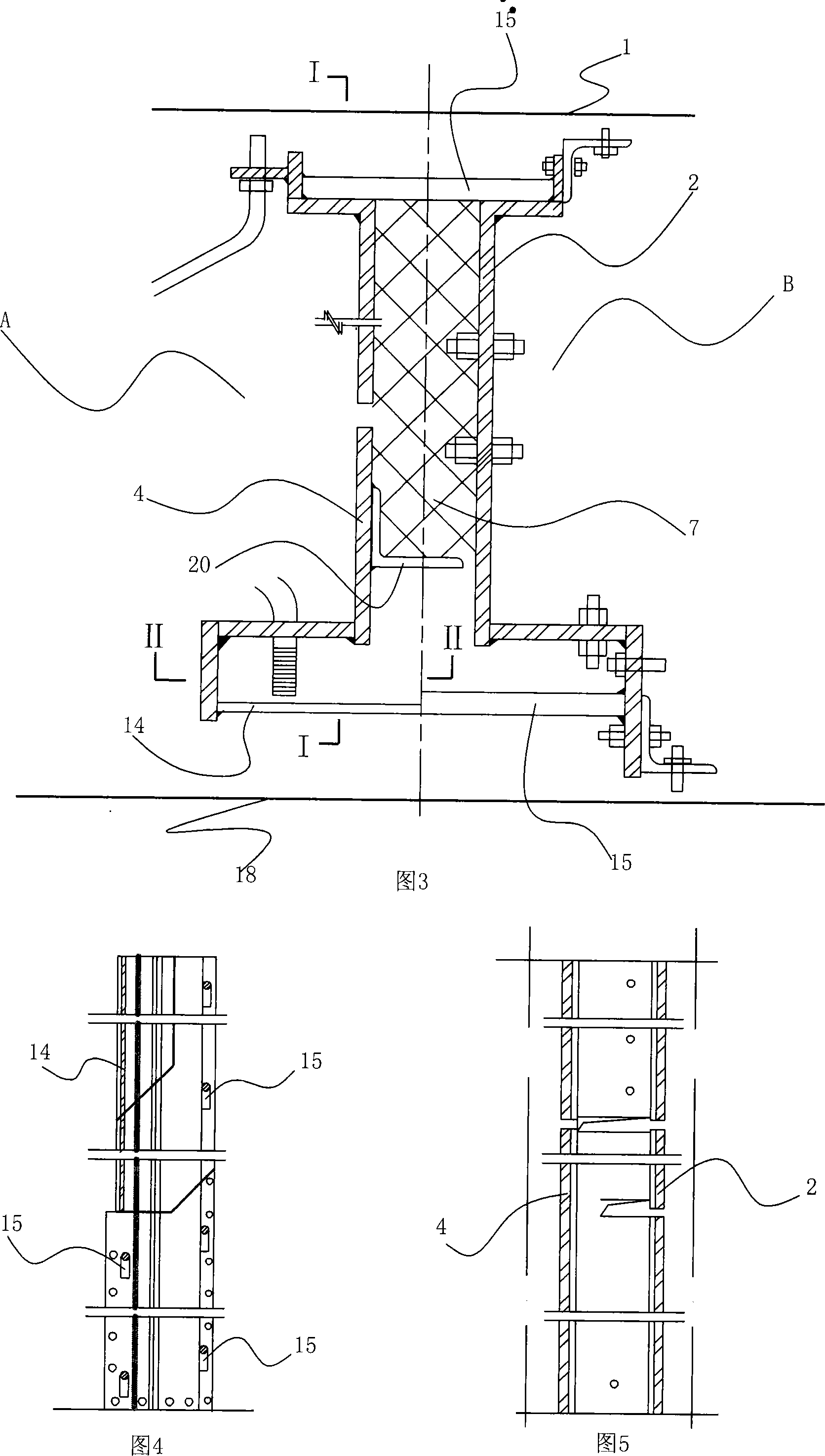

[0030] As shown in Fig. 1, Fig. 2 and Fig. 3, the positions of the settlement joints 13 are determined according to the specific settlement conditions of the main building 6 and the skirt building 9, and the settlement amounts of the underground diaphragm walls 12 on both sides of the settlement joints 13 are different.

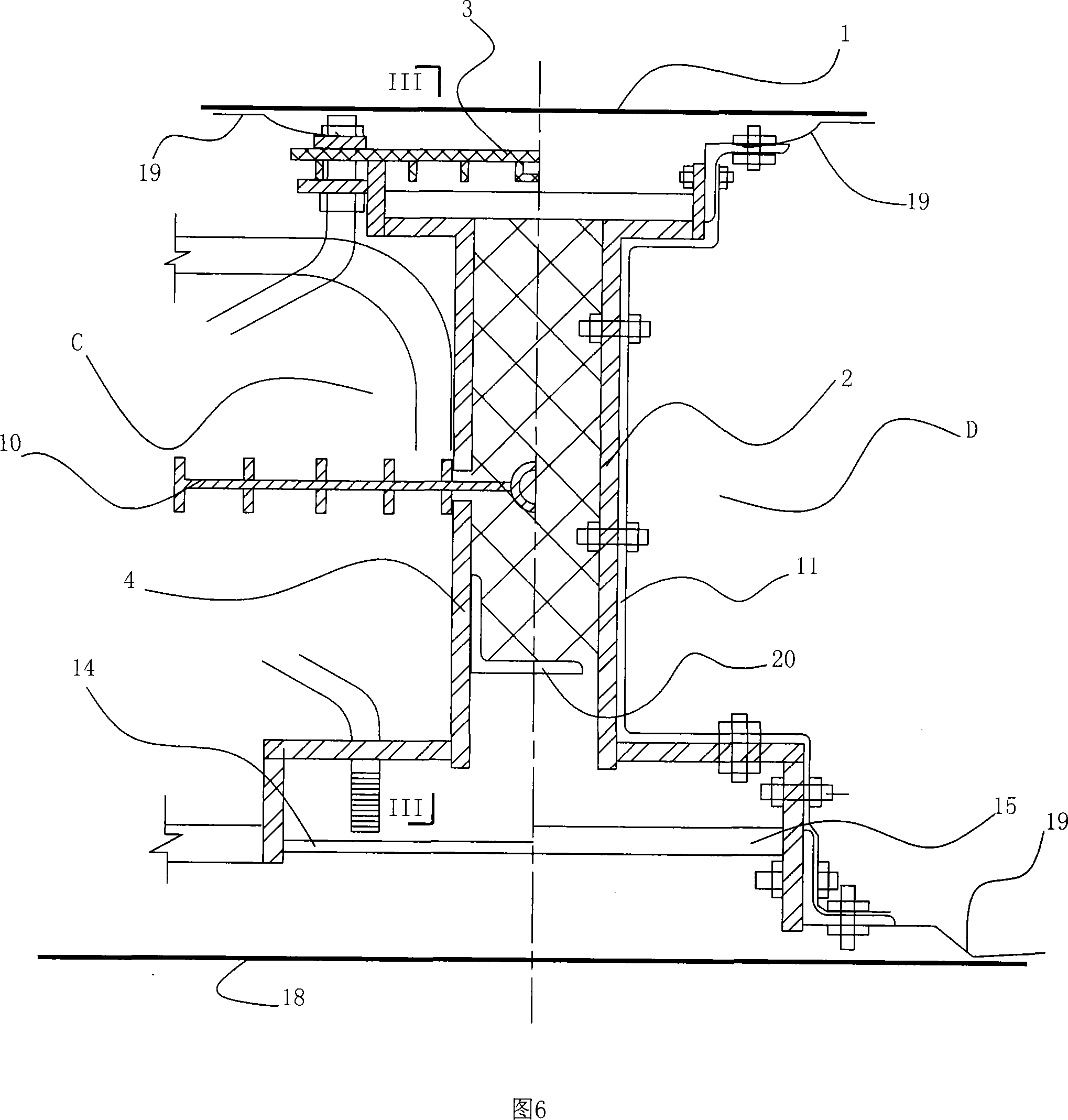

[0031] As shown in Fig. 3, Fig. 4, Fig. 5, Fig. 6 and Fig. 10, Fig. 11, according to the size of the settlement joint and construction requirements, two full-length special-shaped steel plates, namely the left special-shaped steel plate 4 and the right special-shaped steel plate 2, are fabricated off-site. Transport the completed full-length special-shaped steel plate to the construction site, and after passing the inspection, assemble and weld the reinforcement cage 21 and the full-length special-shaped steel plate on the ste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap