Windmill and wind power generator composed of the same

A wind power generation device and windmill technology, which is applied to wind turbines, wind energy power generation, wind turbines and other directions that are consistent with the wind direction, and can solve problems such as the influence of generators and the uneven rotation speed of windmills.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

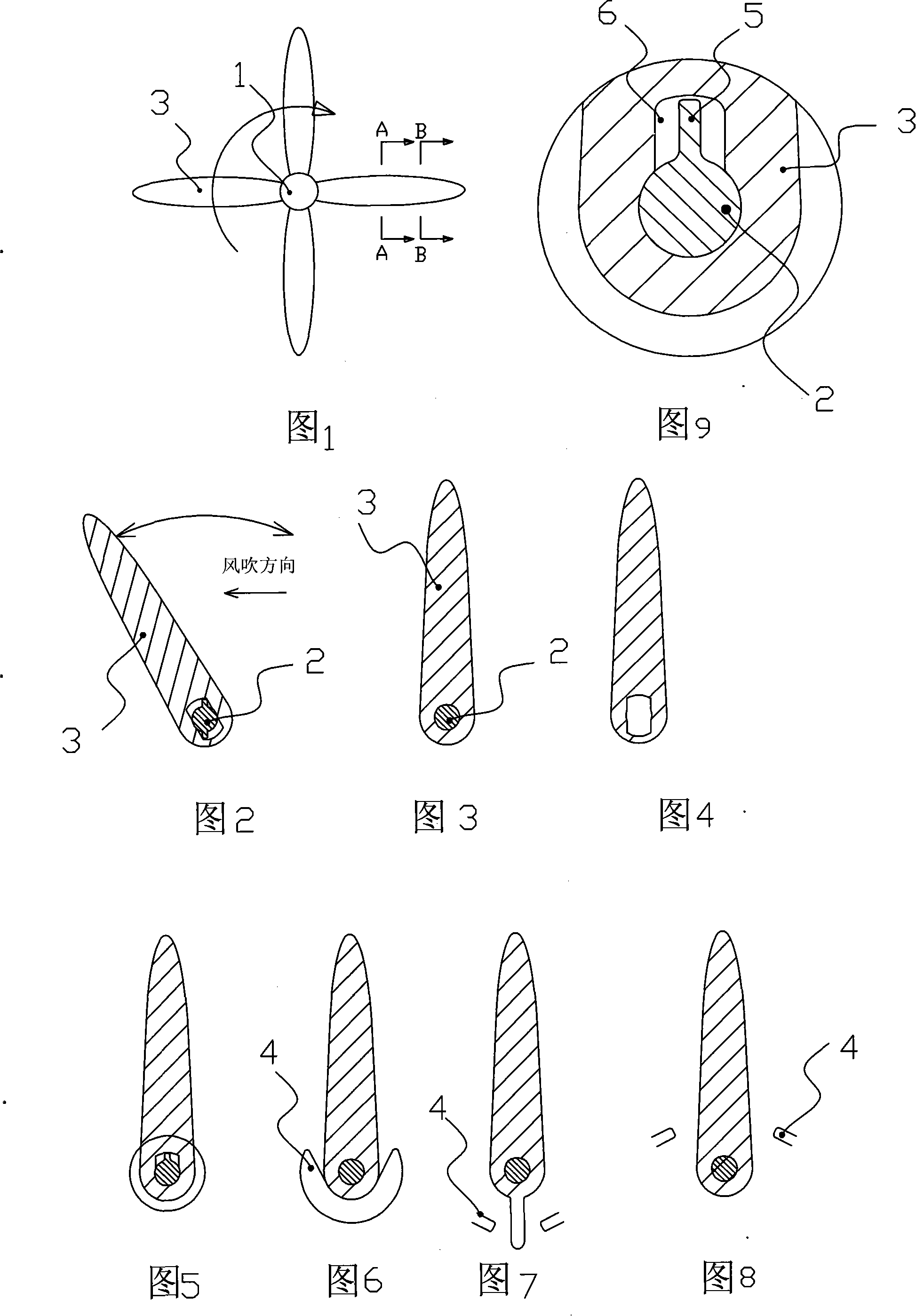

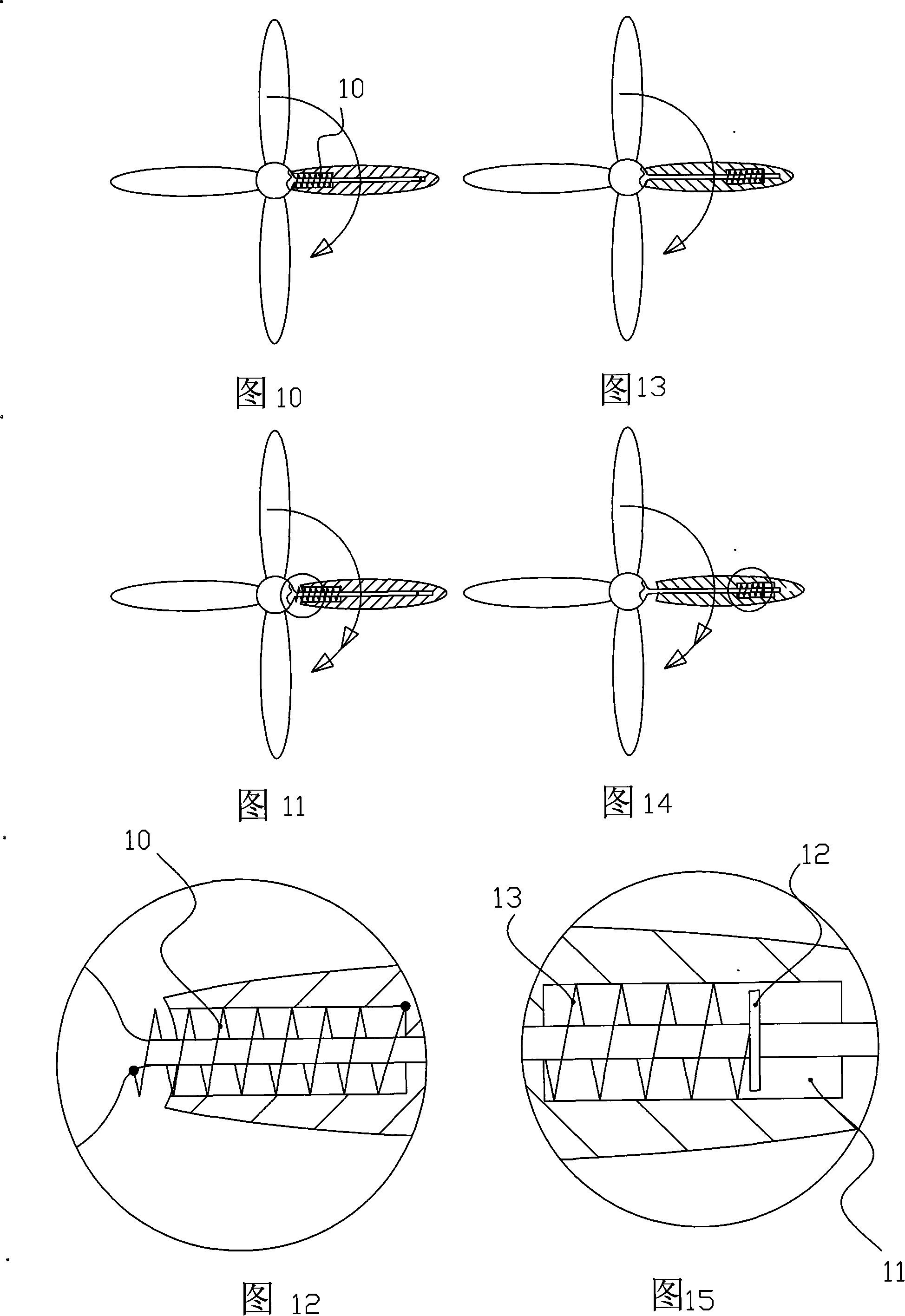

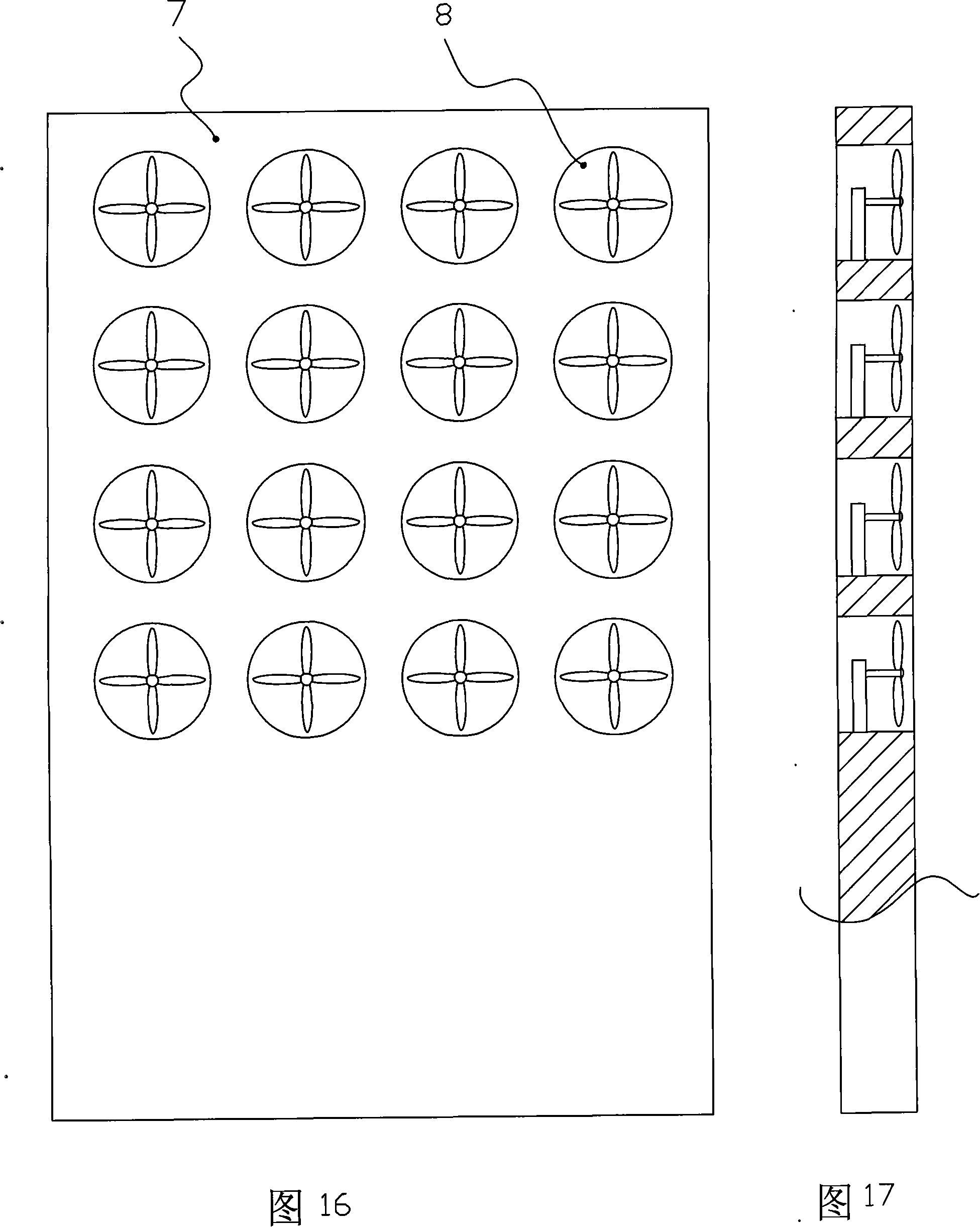

[0043] As shown in Figures 1 to 4, the windmill embodiment 1 of the present invention includes a wind wheel composed of a horizontal shaft 1 and blades 3, the blades are swingably supported on a blade shaft 2 vertically fixed on the horizontal shaft 1, The axis of the blade shaft is parallel to the length direction of the windmill blade and is biased to the blade edge on one side of the blade. The horizontal shaft or the blade shaft is provided with a blade swing limit mechanism. The swing limit mechanism in this example is: the blade shaft passes through the blade shaft hole Among them, there is at least one radial protrusion on the blade shaft, and a radial groove is opened at the blade shaft hole corresponding to the radial protrusion, see Figure 2, which is a schematic diagram taken along the A-A line of Figure 1, the present example The radial protrusion is protruding at both ends, and the blade shaft hole corresponding to the radial protrusion has a radial groove 6, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com