Dynamical pressure gas elasticity foil bearing with stability self-adaptive control function

An adaptive adjustment and elastic foil technology, applied in the field of bearings, can solve the problems that the active control and adaptive adjustment of system vibration cannot be realized, and achieve the effects of meeting real-time control requirements, increasing bearing capacity, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

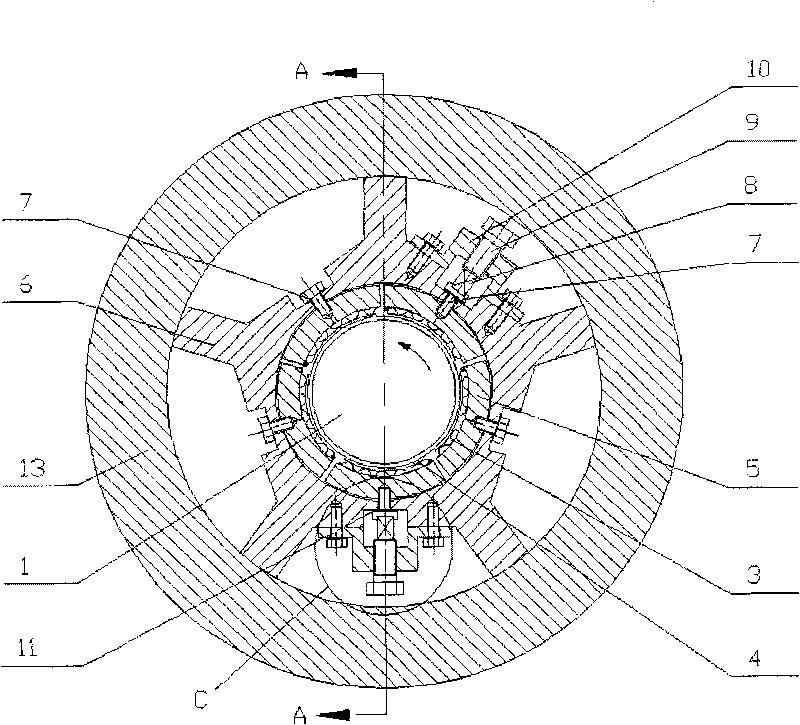

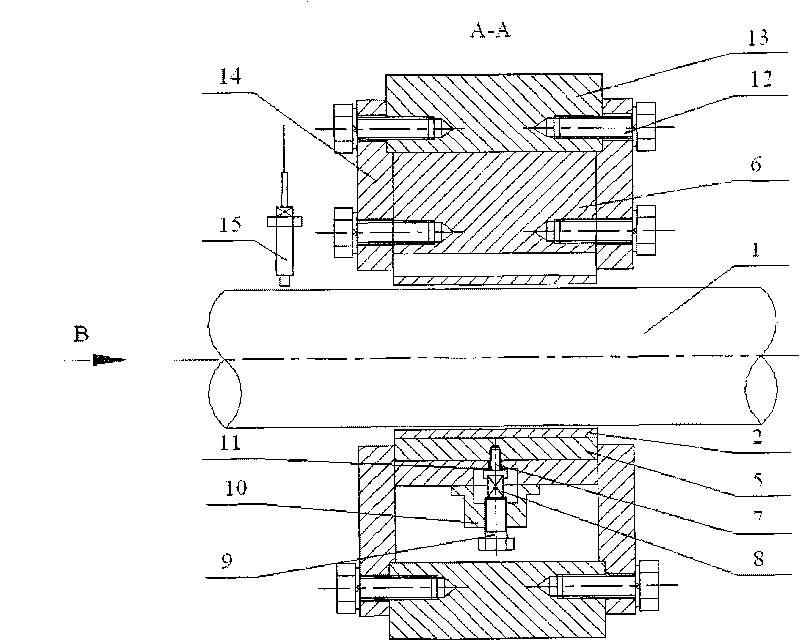

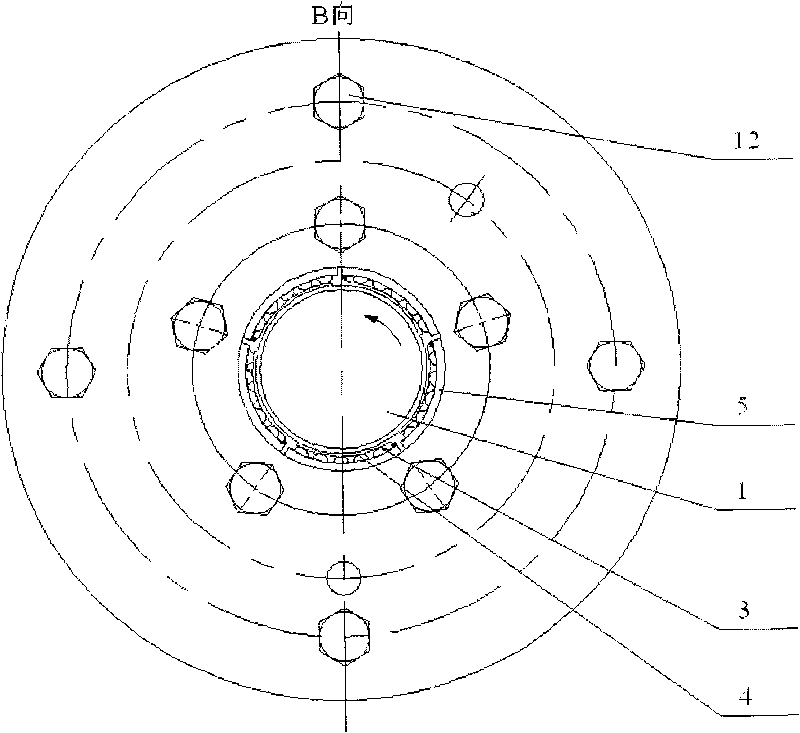

[0019] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] see figure 1 , figure 2 , image 3 , a dynamic pressure gas elastic foil bearing with the function of self-adaptive adjustment of stability, including a bearing housing 6, a bearing pad 5, an elastic foil 2 and a piezoelectric ceramic micro-displacement actuator 8, five bearing pads 5 are evenly distributed along the inner wall of the bearing housing 6, and the positioning screws 7 pass through the through holes on the bearing housing 6 and are screwed into the threaded holes on the bearing pad 5, and the bearing pad 5 is installed on the inner wall of the bearing housing 6 and limit the swing of the bearing pad 5. The elastic foil 2 is composed of the bottom arch foil 3 and the top layer foil 4. One end of the bottom arch foil 3 and the top layer foil 4 is welded on the bearing pad 5, and the top la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com