Coupling light element

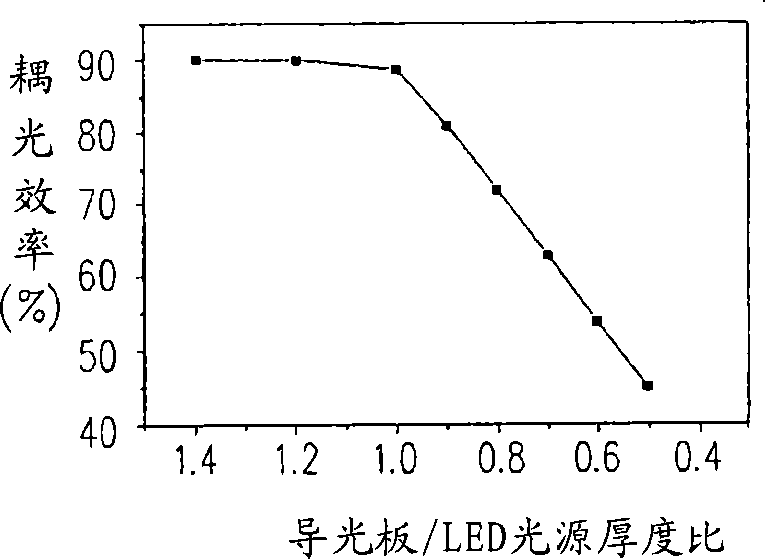

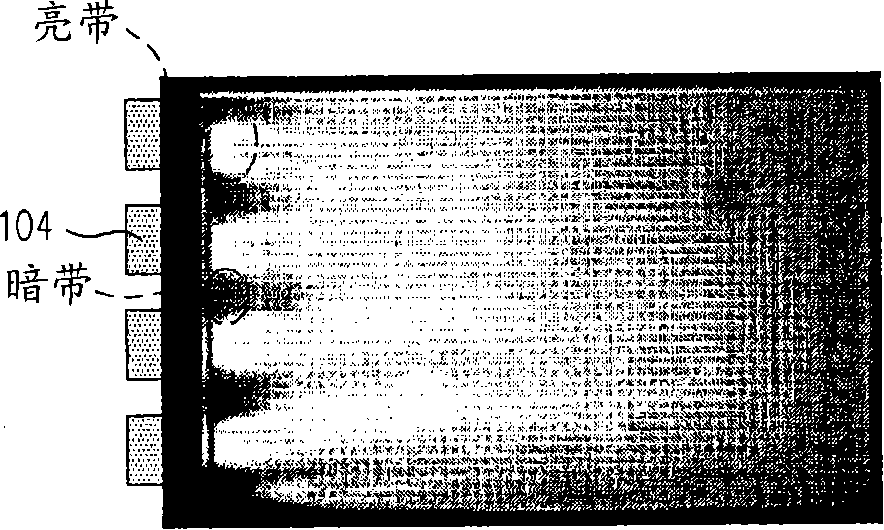

A component and light source technology, which is applied in the field of light coupling components, can solve problems such as uneven bright bands/dark bands on the light coupling end surface of the light guide plate, and insufficient luminance of the light guide plate, so as to improve the phenomenon of uneven brightness and avoid damage to Bit error, the effect of improving the coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

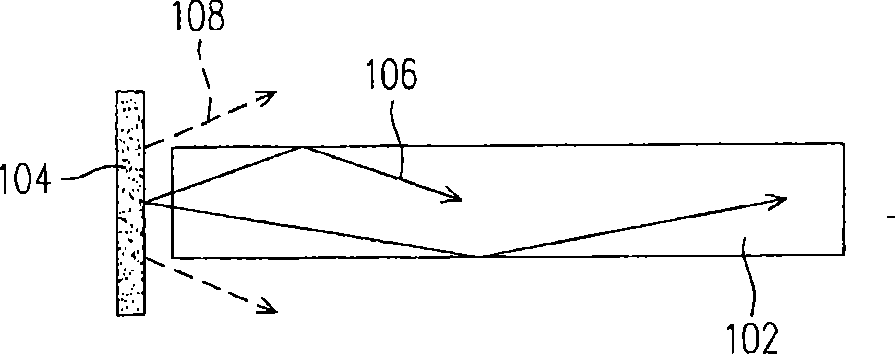

[0052] Please refer to image 3 , which is a three-dimensional schematic diagram of the light coupling element according to the first embodiment of the present invention. The light coupling element 300 in this embodiment includes a reflection cavity 302 , a light guide plate 304 and a light source 306 .

[0053] Wherein, the reflection cavity 302 has an opening 308 . The reflecting cavity 302 is composed of an upper surface 310 , a lower surface 312 , a first side surface 314 , a second side surface 316 and an end surface 318 corresponding to the opening 308 . The upper surface 310 and the lower surface 312 of the reflective cavity 302 are mirror reflection surfaces, and the reflection characteristics of the first side surface 314 , the second side surface 316 and the end surface 318 may be the same or different, which may be mirror reflection surfaces or diffuse reflections surface (diffusive reflector). In addition, the upper surface 310 of the reflection cavity 302 in th...

no. 2 example

[0060] Please refer to Image 6 , which is a schematic cross-sectional view of the light coupling element according to the second embodiment of the present invention. The light coupling element 400 of this embodiment is similar to the light coupling element 300 of the first embodiment, and the main difference is that the light source 306 is disposed inside the reflection cavity 302 and is located on the side of the end face 318 .

no. 3 example

[0062] Please refer to Figure 7 , which is a schematic cross-sectional view of the light coupling element according to the third embodiment of the present invention. The light coupling element 500 of this embodiment is similar to the light coupling element 300 of the first embodiment, but the main difference is that the light source 306 is disposed on the end face 318 , and part of the light source 306 is located outside the reflection cavity 302 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com