Stowage method of million kilowatt units principal circle reactor core of Chinese press water stack nuclear power station

A pressurized water reactor nuclear power plant and first cycle technology, applied in nuclear power generation, assembly of fuel elements, nuclear engineering, etc., can solve the problems of inflexible design, excessive radioactive waste, unfavorable environmental protection, etc., to achieve environmental protection and reduce radioactivity Effects of waste, high economy and operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

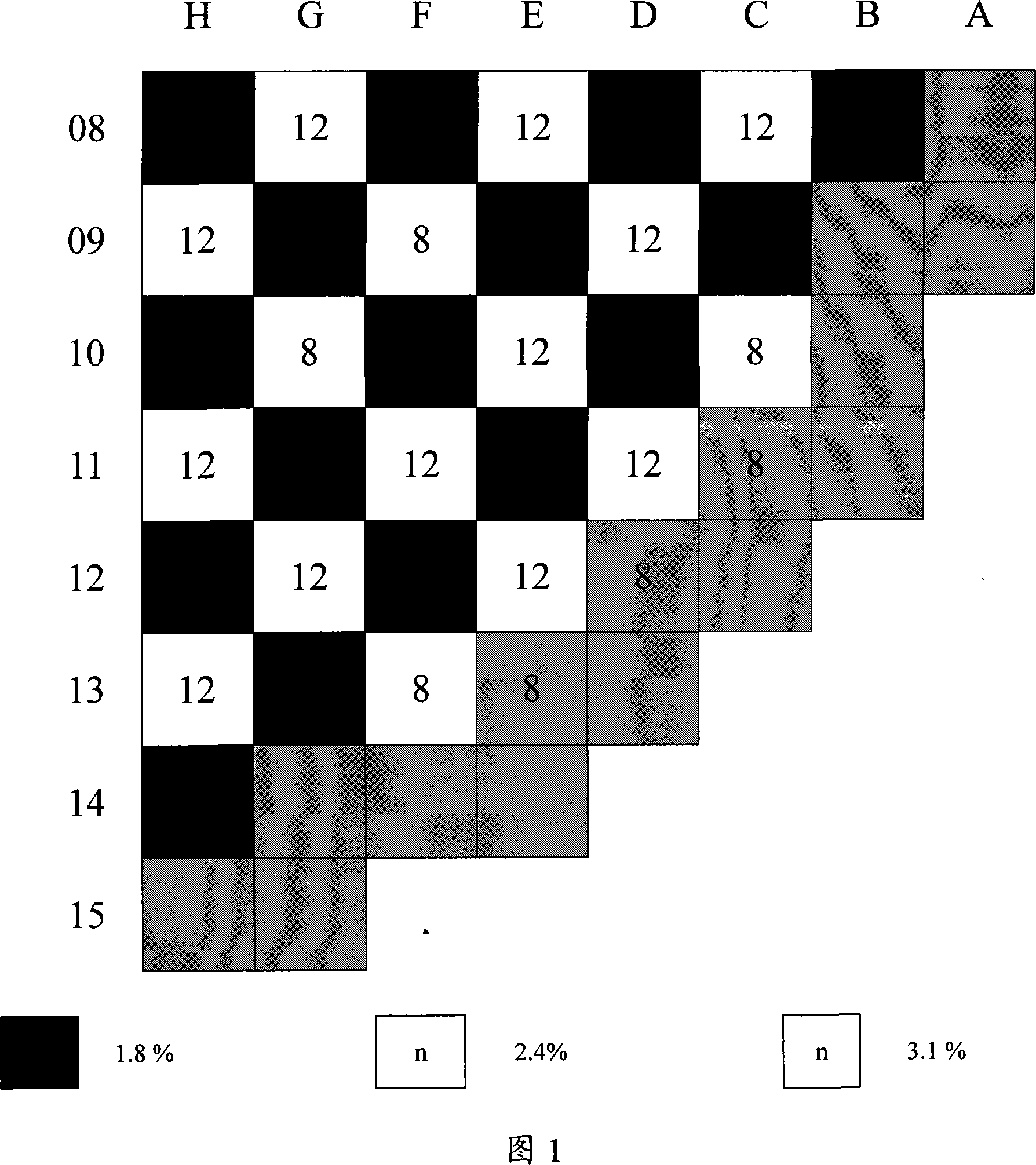

[0010] In the embodiment of the present invention, in the first cycle, gadolinium is used as the burnable poison, and the in-stack arrangement of fuel assemblies is changed to achieve a cycle length of 346 equivalent full power days in the first cycle.

[0011] The reactor core of the pressurized water reactor nuclear power plant is composed of 157 sets of AFA3G fuel assemblies of all M5 materials. The height of the core fuel active section is 365.76cm, the equivalent diameter is 304.04cm, and the height-to-diameter ratio is 1.203. The fuel rods of each full M5 AFA 3G fuel assembly are arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com