Soil stripping device

A technology for stripping equipment and soil, which is applied in earth movers/shovels, excavators, mechanically driven excavators/dredgers, etc., and can solve complex brake equipment and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

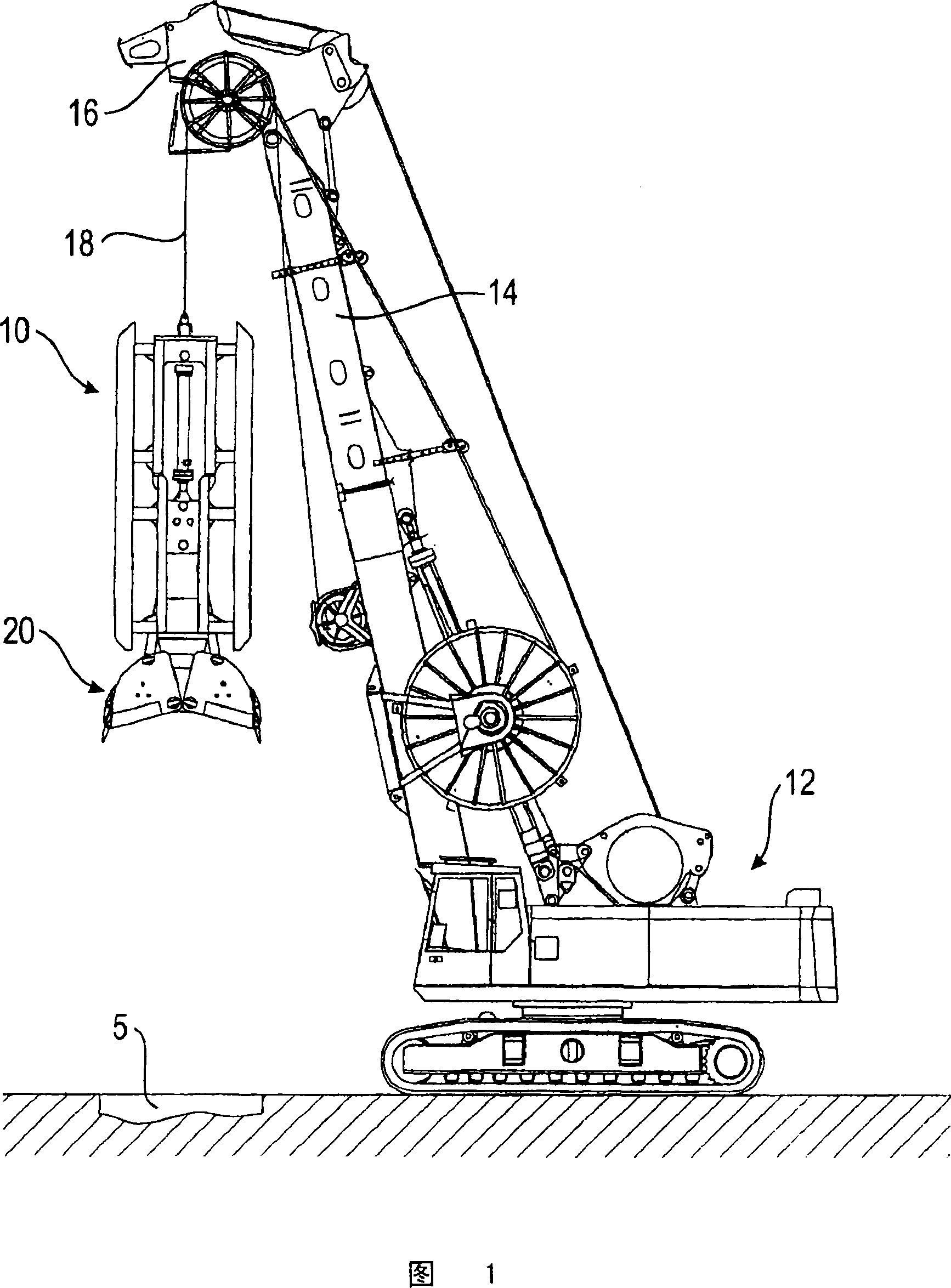

[0028] The basic construction of a soil stripping device 10 according to the invention for forming a trench 5 in soil is schematically shown in FIG. 1 . A working unit 20 for excavating a trench 5 is arranged vertically displaceable on a carrier 12 by means of a lifting device 18 consisting of several support cables, wherein the carrier has a mast head 16 The approximately vertically oriented mast 14 .

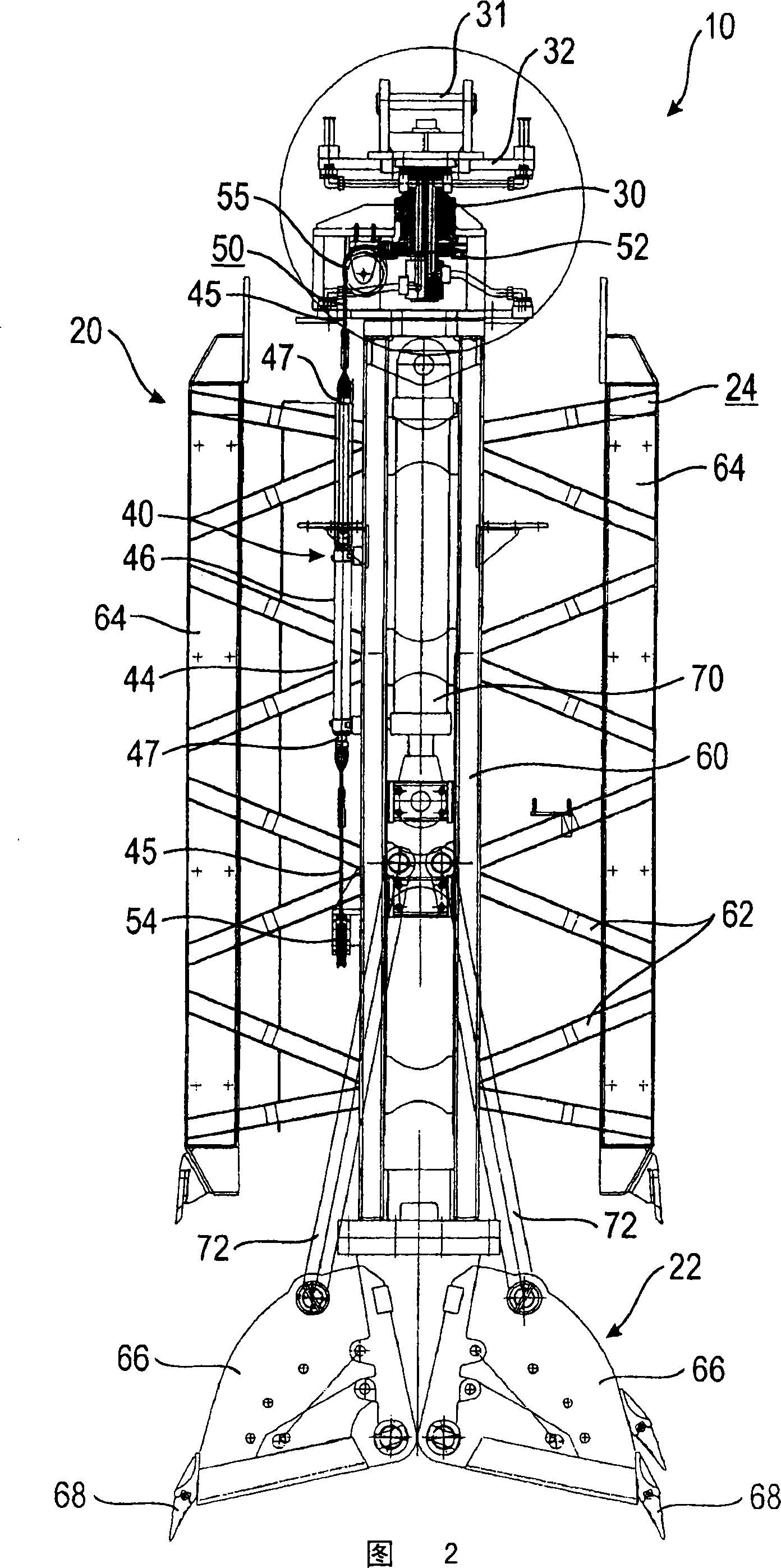

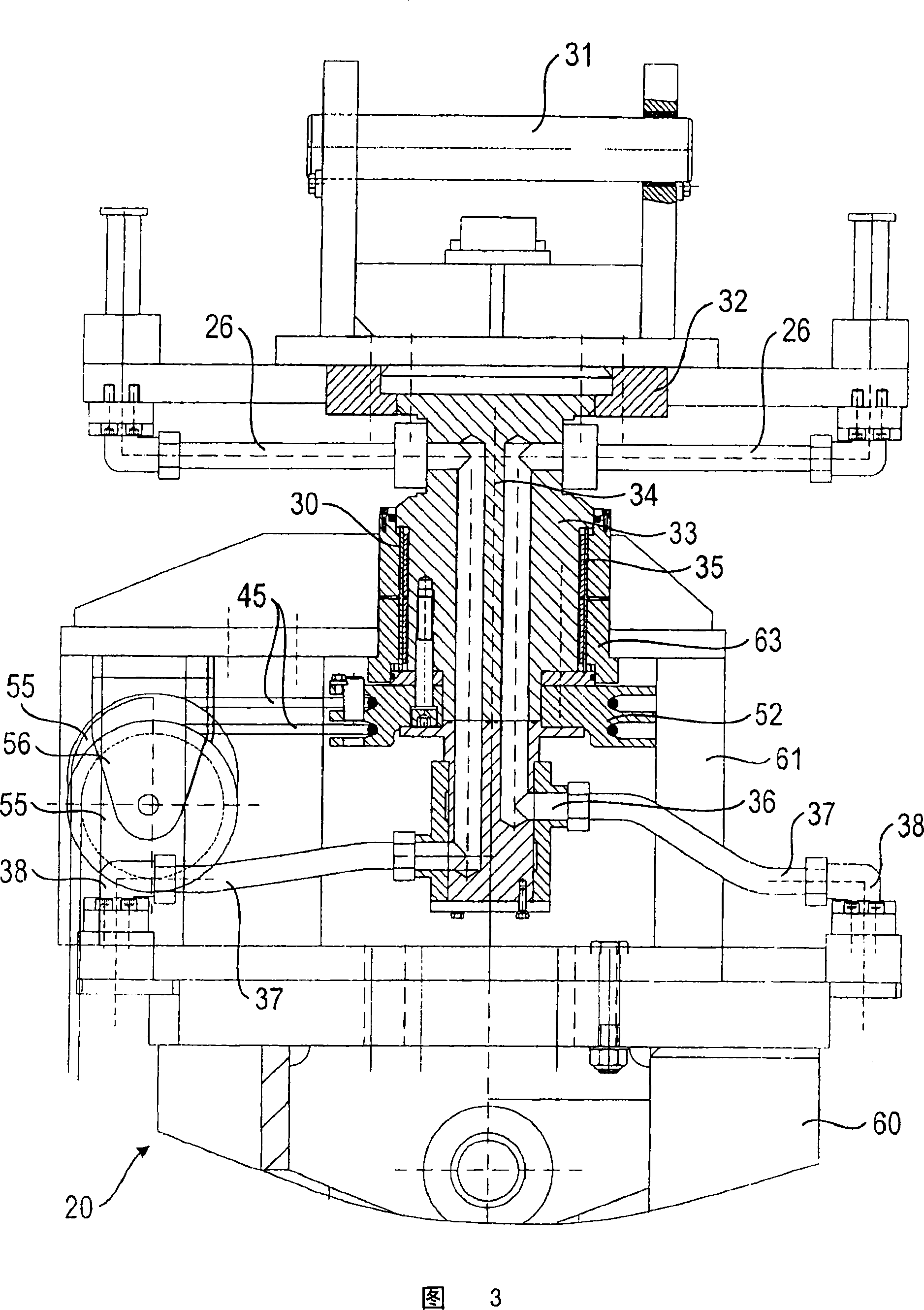

[0029] According to FIG. 2 , a soil stripping device 10 according to the invention is shown designed as a ditch wall grab. The ditch wall grab comprises a frame 24 with a centrally arranged longitudinal girder 60 , on which lateral guide plates 64 are arranged in a known manner via crossbars 62 . Two grappling blades 66 with teeth 68 pivot at the lower end of the longitudinal spar 60 to act as the soil stripping tools 22 . By means of a hydraulically actuated cylinder 70 centrally located on the longitudinal spar 60, the grab blade 66 can be opened or closed by means of an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com