Copper wire tin-plating drier

A copper wire tin-plating and drying technology, applied in progressive dryers, dryers, drying solid materials, etc., can solve the problems of copper wire quality decline, long time, poor drying effect, etc., to speed up work efficiency , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

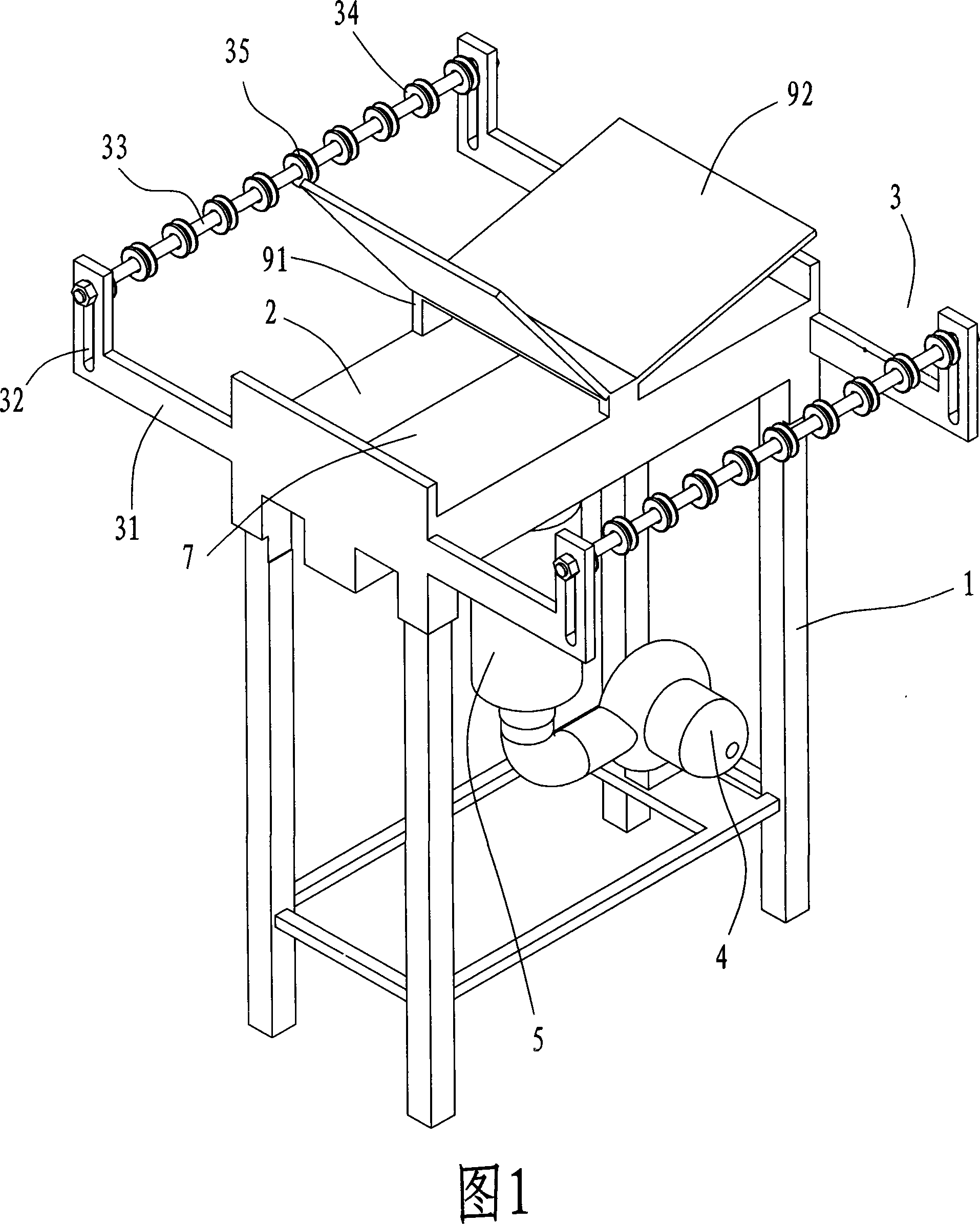

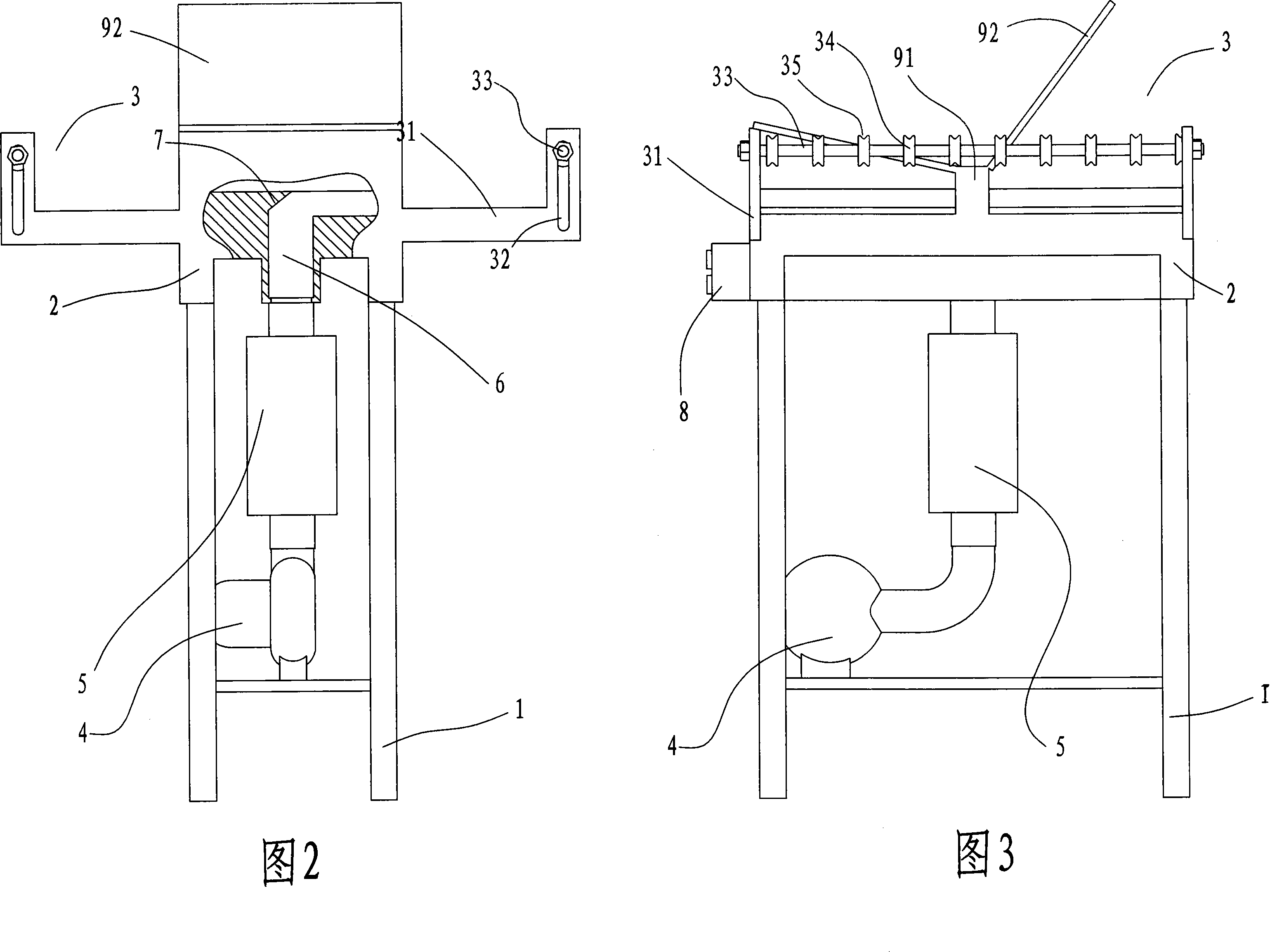

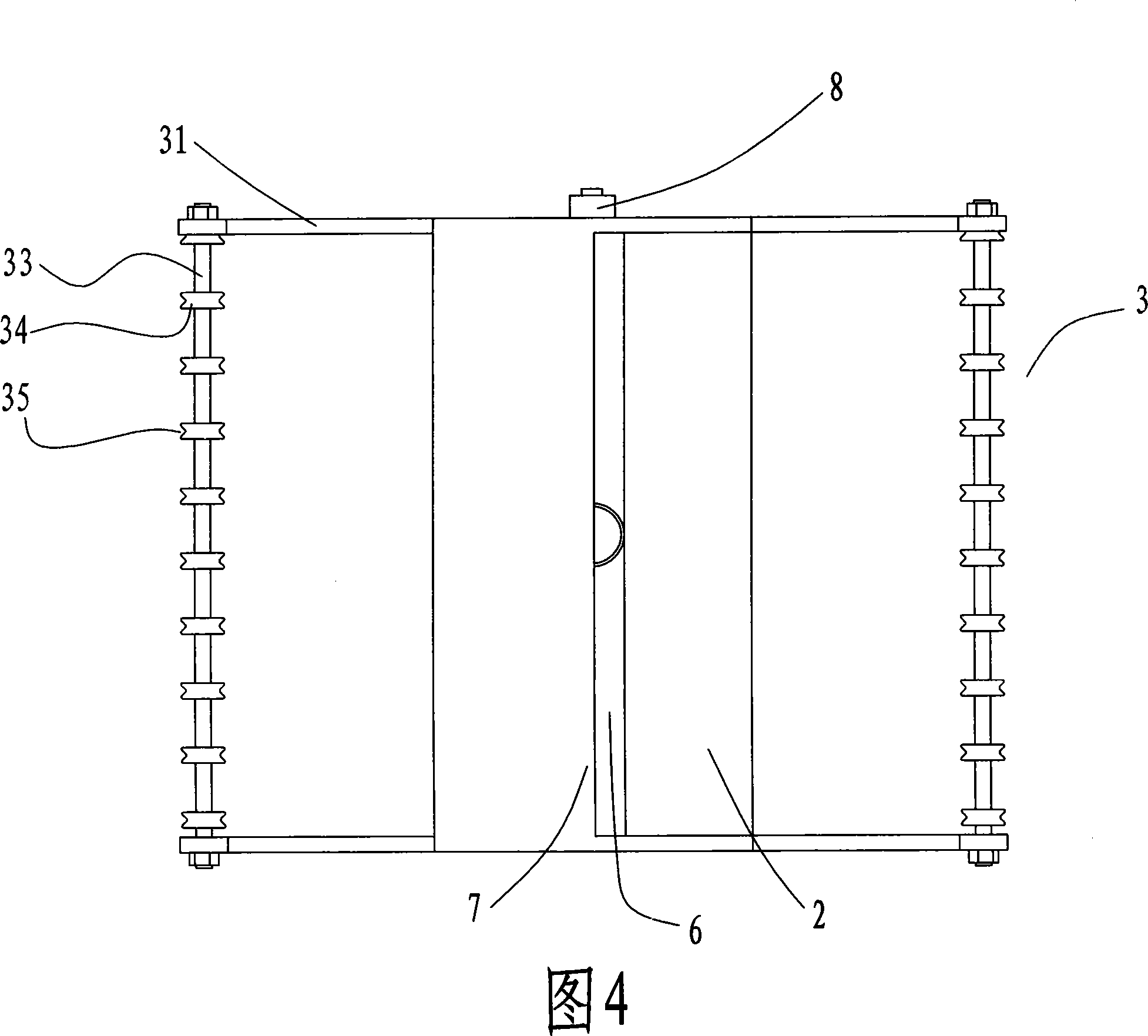

[0015] Below in conjunction with accompanying drawing, specific embodiment is described:

[0016] As shown in Fig. 1, Fig. 2, Fig. 3, and Fig. 4, a copper wire tinning dryer includes a frame 1, a workbench 2 is arranged on the upper plane of the frame 1, and a workbench 2 is arranged on the outer wall of both sides of the workbench 2. Wire outlet device 3; the wire inlet and outlet device 3 includes two upwardly extending L-shaped struts 31 protruding from both ends of the opposite side walls of the workbench 2, and the short struts of the L-shaped struts 31 are There is a long hole 32 in the longitudinal direction, and a wheel shaft 33 is threaded between the two long holes 32, and several rotating wheels 35 are sleeved at intervals on the wheel shaft 33, and an annular groove 35 is provided on the rotating wheel 34; the middle part of the workbench 2 A downwardly sunken air distribution groove 6 is provided, and the bottom of the air distribution groove 6 is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com