Fan and motor thereof

A technology for motors and bearing housings, applied in the field of fans and their motors, which can solve problems such as inability to meet adjustment needs, weakening of the magnetic field, and influence on the characteristics of the motor 10, so as to improve reliability, reduce distance, and avoid component wear and noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A fan and its motor according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference symbols.

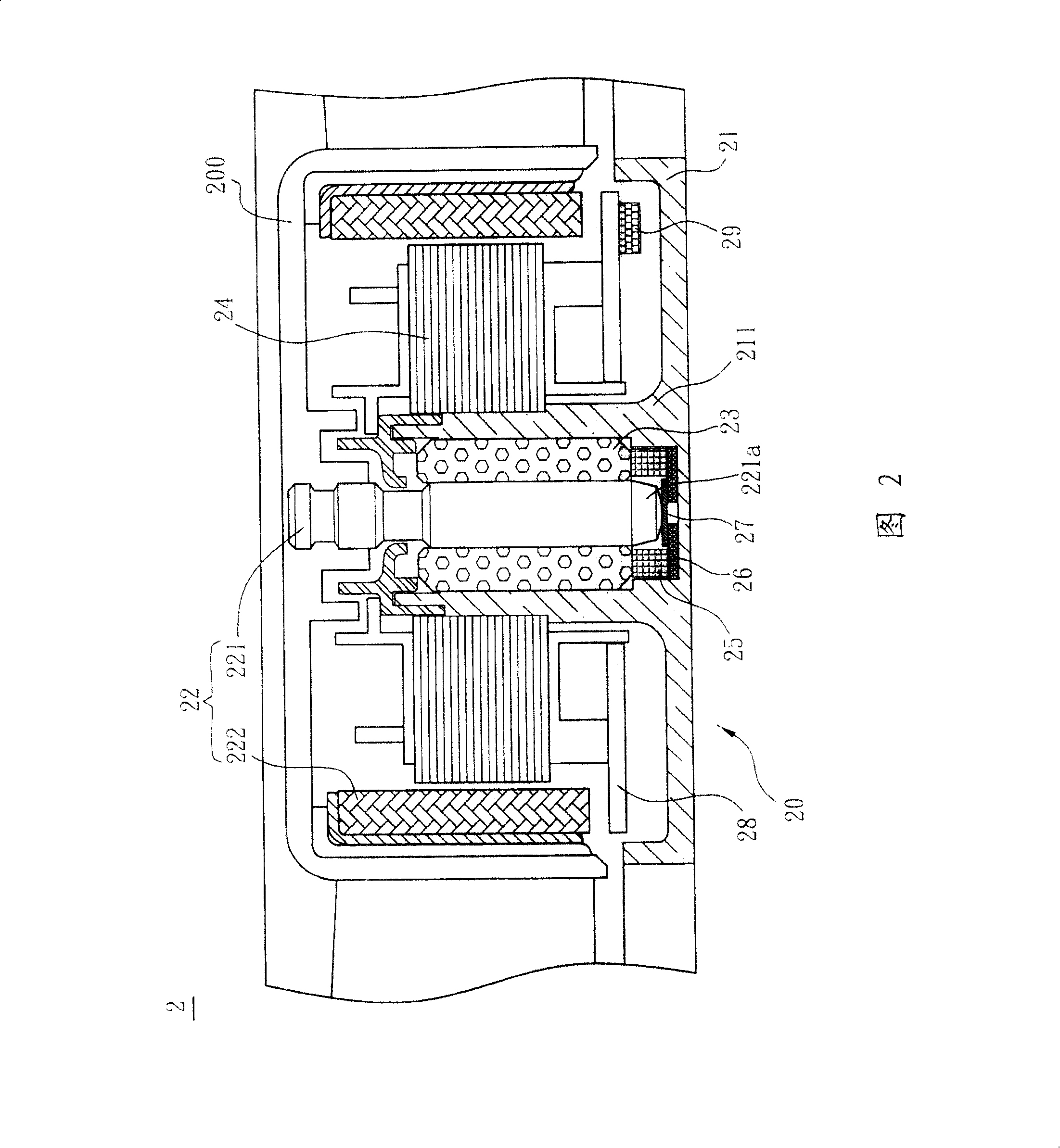

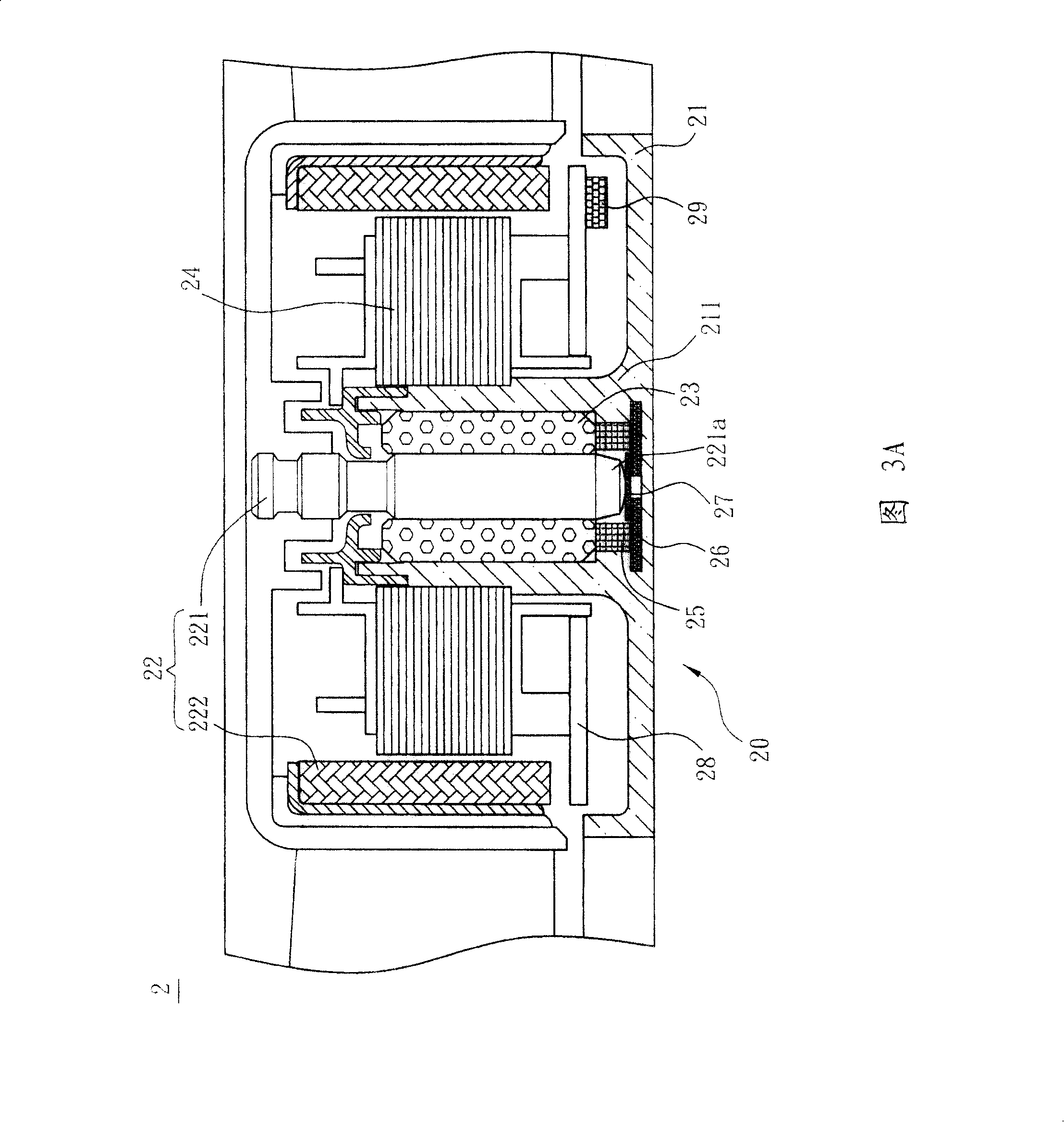

[0027] See also shown in Fig. 2, a kind of fan 2 of preferred embodiment of the present invention comprises a motor 20 and an impeller 200, and motor 20 drives impeller 200 to rotate, and motor 20 comprises a base 21, a bearing 23, a stator 24, a The rotor 22 and a magnetic body 25 . The center of the base 21 extends to form a bearing seat 211, the bearing 23 is accommodated in the bearing seat 211, the stator 24 is placed on the outer periphery of the bearing seat 211, the rotor 22 has a rotating shaft 221 and a magnetic ring 222, the magnetic ring 222 and The stator 24 is arranged correspondingly. The stator 24 is formed by winding a plurality of silicon steel sheets with a coil, and the rotating shaft 221 is passed through and installed on the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com