Method of preparing micro needle array syringe

A technology for microneedle arrays and syringes, which is applied in the field of preparation of microneedle array syringes, can solve the problems of impossibility to apply low-cost hollow microneedle arrays, limit the application field and scope, etc., achieve short preparation cycle, reduce preparation cost, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

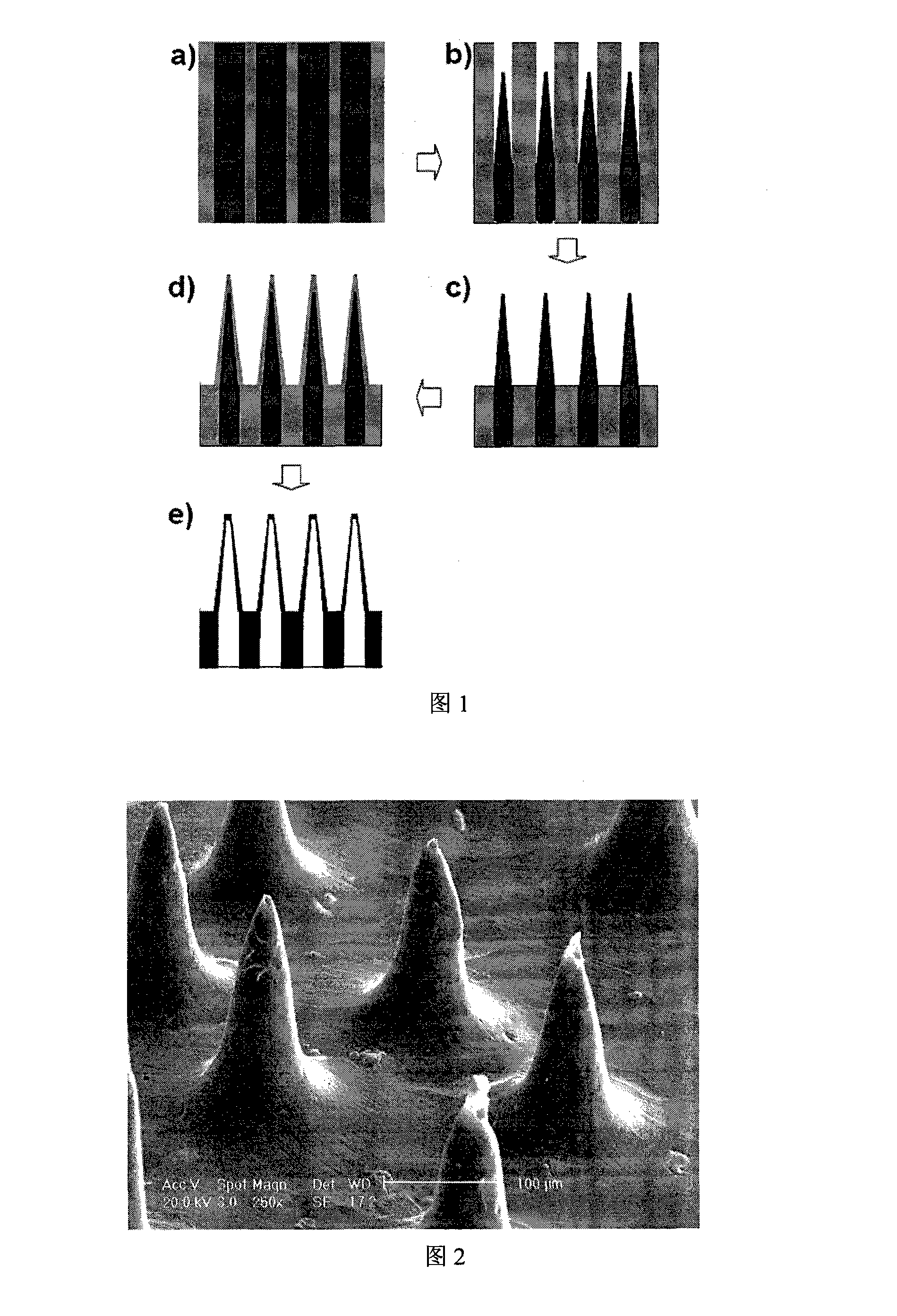

Method used

Image

Examples

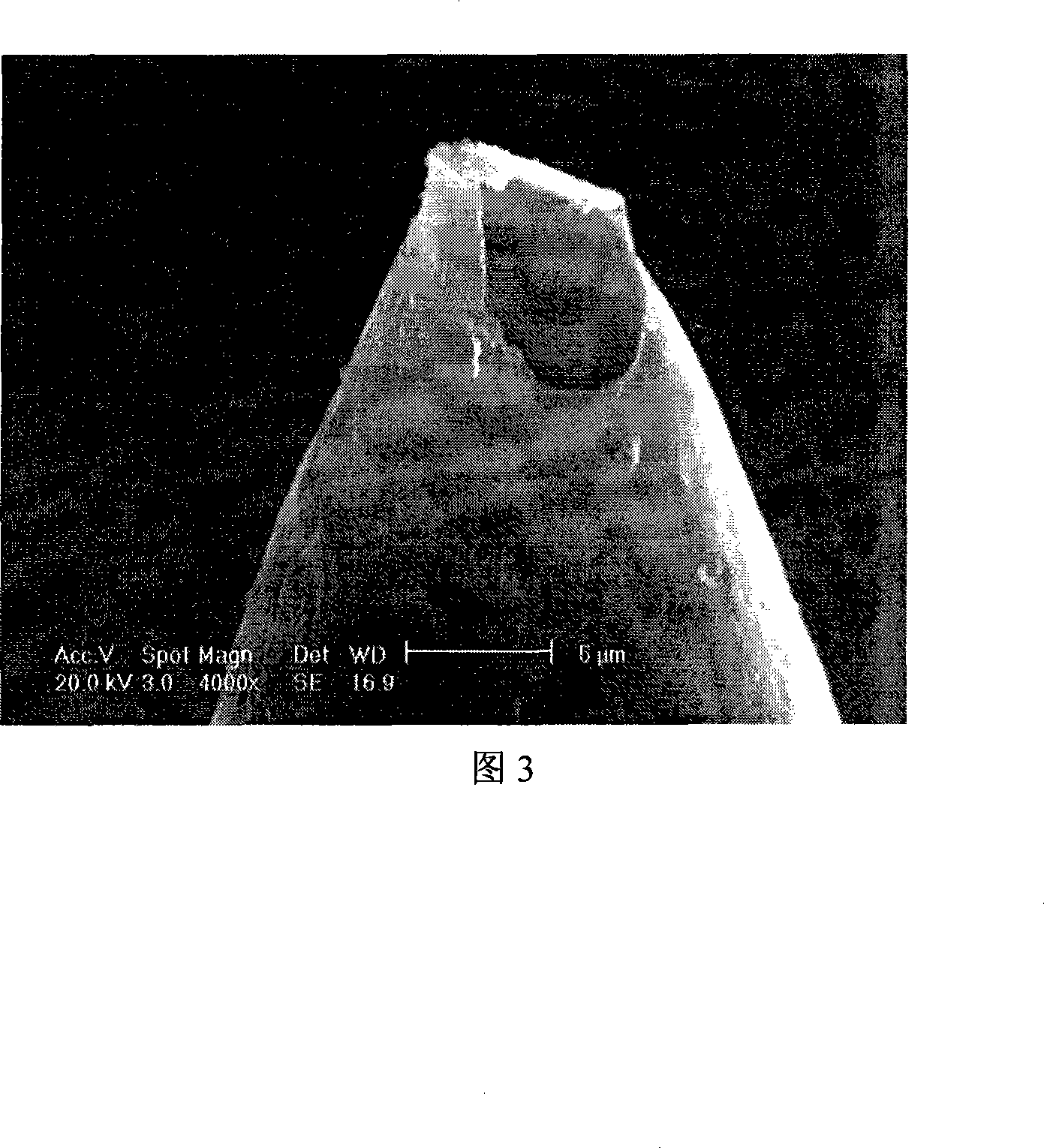

Embodiment 1

[0022] Example 1: SiO with a fiber diameter of 100 microns 2 Put the fiber bundle into the MMA (polymethyl methacrylate) solution added with BPO, place it in a water bath at 60 ° C for 24 h to cure the polymer, and then cut it into thin slices with a thickness of 5 mm, and use 40% HF acid solution for 30 Corrosion at a constant temperature of ℃ for 1 h, ultrasonic cleaning with deionized water, and drying to obtain the nanoneedle array. Then put into the chloroform solution and dissolve for 20min, after drying, use the spin coating method to spin-coat PMMA with a thickness of 20um on the surface, put it into a 40% HF acid corrosion solution and corrode it for 5h at a temperature of 30°C to obtain the PMMA material. Hollow Microneedle Array Syringes.

Embodiment 2

[0023] Embodiment 2: SiO with a fiber diameter of 8 microns 2 Put the fiber bundle into a styrene solution with lithium hexamethyleneimide, place it in a water bath and heat treat at 60°C for 24 hours to solidify the polymer; then cut it into thin slices with a thickness of 3mm; use 20% The HF acid solution was corroded for 30 min, and the nanoneedle array was obtained after ultrasonic cleaning with deionized water and drying. Then it was dissolved in chloroform solution for 5 minutes, after drying, Au with a thickness of 1 um was deposited on the surface by magnetron sputtering method, and it was put into a 40% HF acid corrosion solution and corroded at 30 ° C for 5 hours to obtain PS as Au-based hollow microneedle array injectors.

Embodiment 3

[0024] Embodiment 3: SiO with a fiber diameter of 20 microns 2 The fiber bundles were immersed in molten polystyrene (PS) resin at 120°C, cooled and sectioned after filling, corroded with 40% HF acid solution for 10 min at a constant temperature of 40°C, ultrasonically cleaned with deionized water, and microneedle arrays were obtained after drying. Then place it on the surface of the polydimethylsiloxane film at 90°C for embossing, then deposit Au with a thickness of 2um on the surface by electroless plating, put it into a 20% HF acid etching solution and etch it at 40°C for 8h , to obtain PS-based Au hollow microneedle array injectors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap