Glass pipe cutting device

A cutting device and technology for glass tubes, applied in the field of tube cutting devices, can solve problems such as unstable product quality, low efficiency, broken glass tubes, etc., and achieve the effects of not being easily broken, stable product quality, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

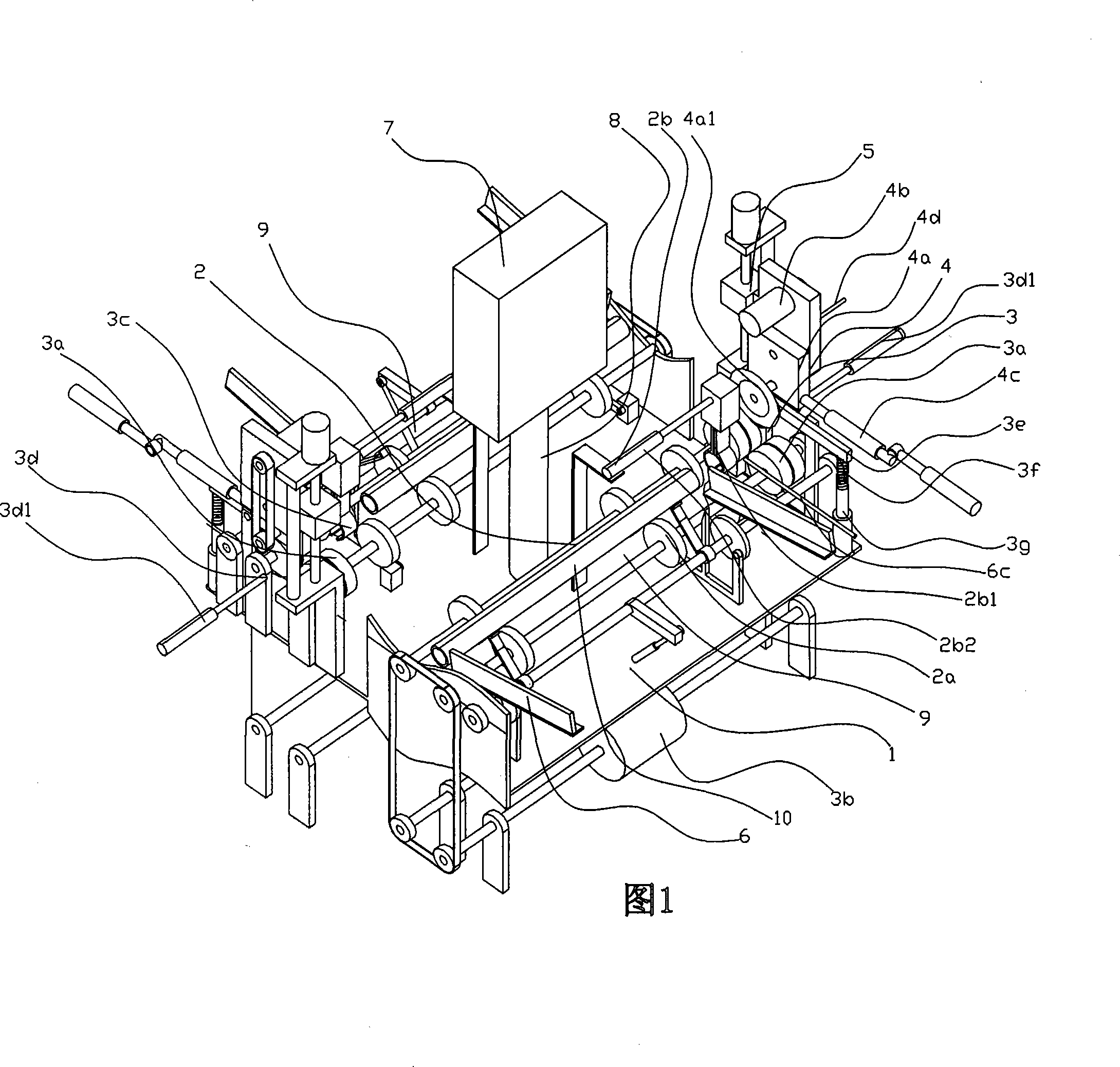

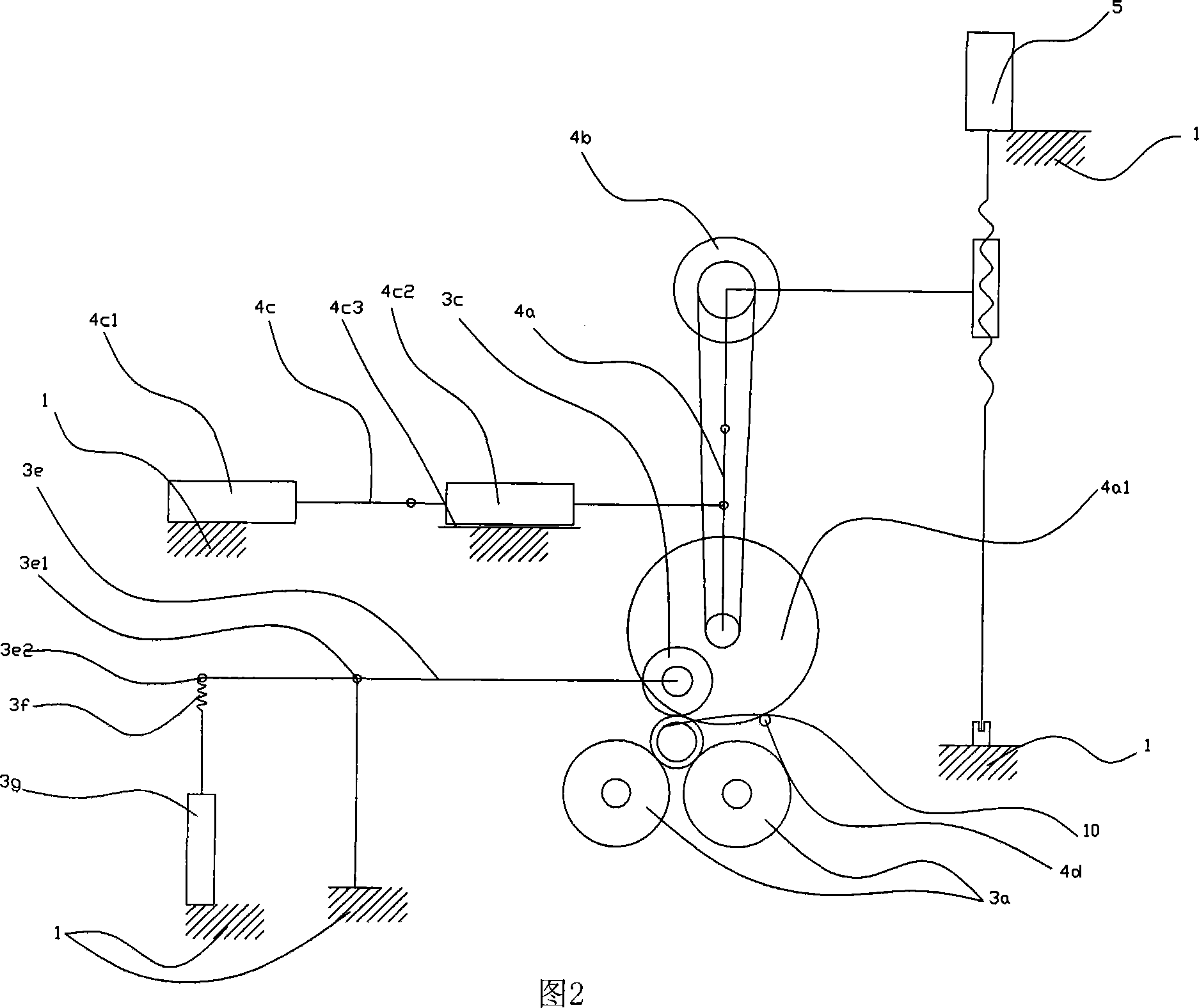

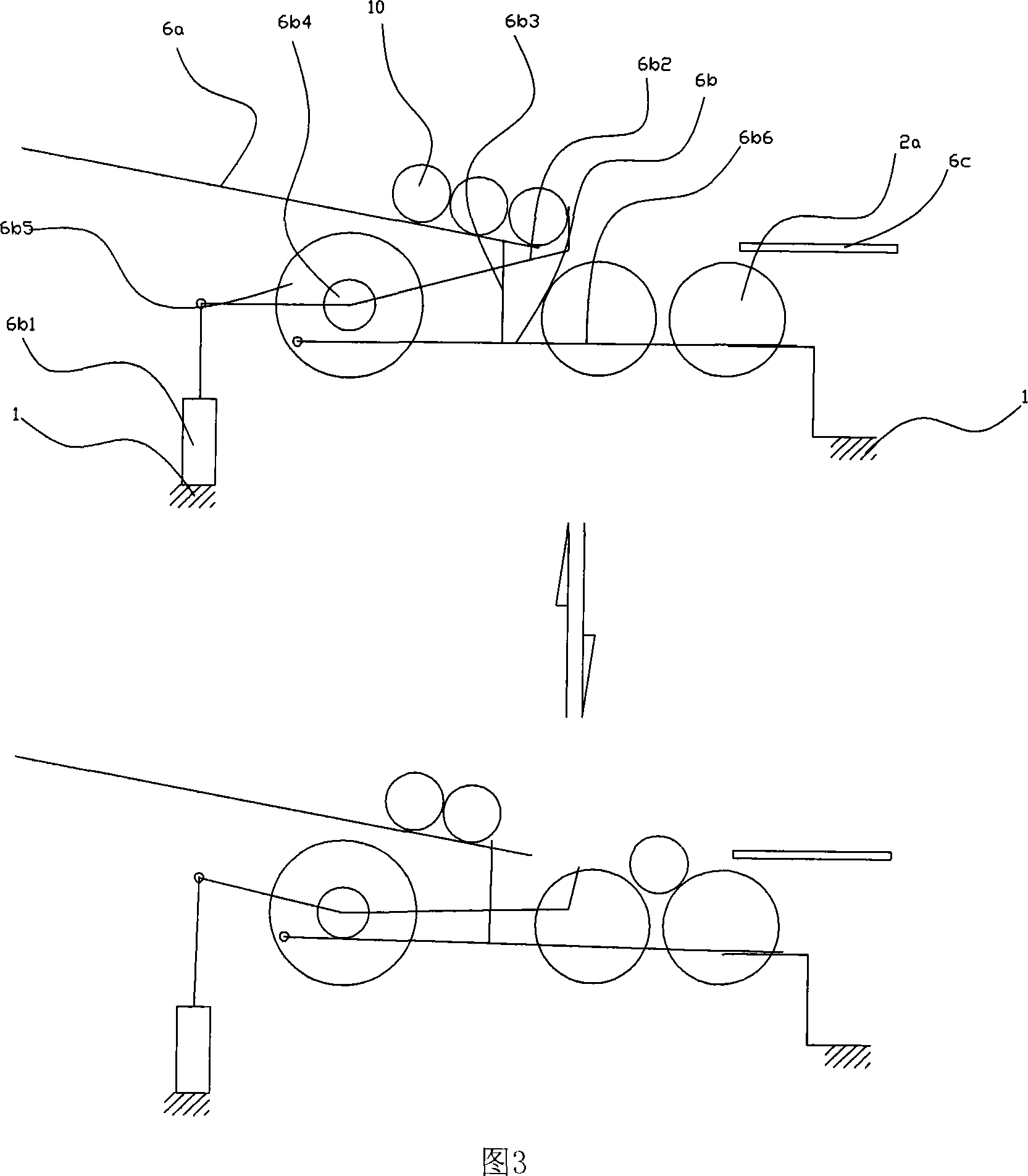

[0014] As shown in Figure 1, the present invention is made up of glass tube conveying device 2, glass tube positioning device 3, glass tube cutting device 4, control device 7 that are arranged on frame 1, and glass tube conveying device 2 consists of conveying track 2a, setting The glass tube pinching device 2b on the conveying track 2a is composed of a glass tube pinching device 2b consisting of a clip 2b1 and a power device 2b2 that drives the clip 2b1 to move back and forth. Wheel 3a, the transmission wheel power mechanism 3b that drives the transmission wheel 3a to rotate, the pressure wheel 3c positioned at the top of the transmission wheel 3a, and the positioning baffle 3d in front of the transmission wheel 3a constitute, and the positioning baffle 3d is connected with the piston rod of the positioning cylinder 3d1, In order to control the position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com