Device for continuously producing polypeptide series products

A series of peptide protein technology, applied in the field of synthesis, can solve the problems of low production efficiency and total production benefits, and achieve the effects of extending the shelf life, reducing storage space, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is now more specifically described by way of examples in conjunction with the accompanying drawings. The present invention will be further described below in conjunction with the accompanying drawings and implementation examples. This implementation example does not limit the application scope of the present invention.

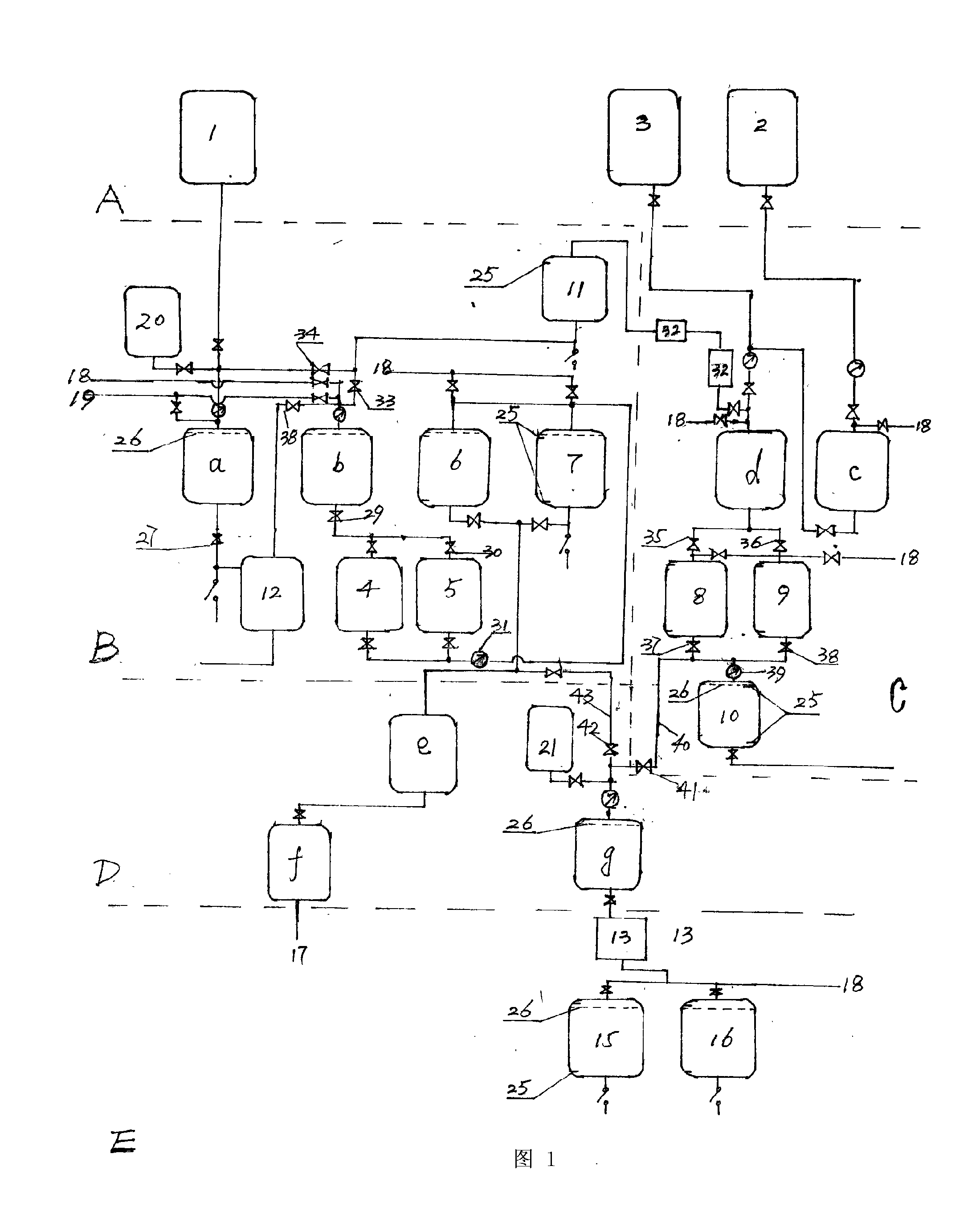

[0025] Figure 1 is a schematic diagram of the installation layout of the present invention.

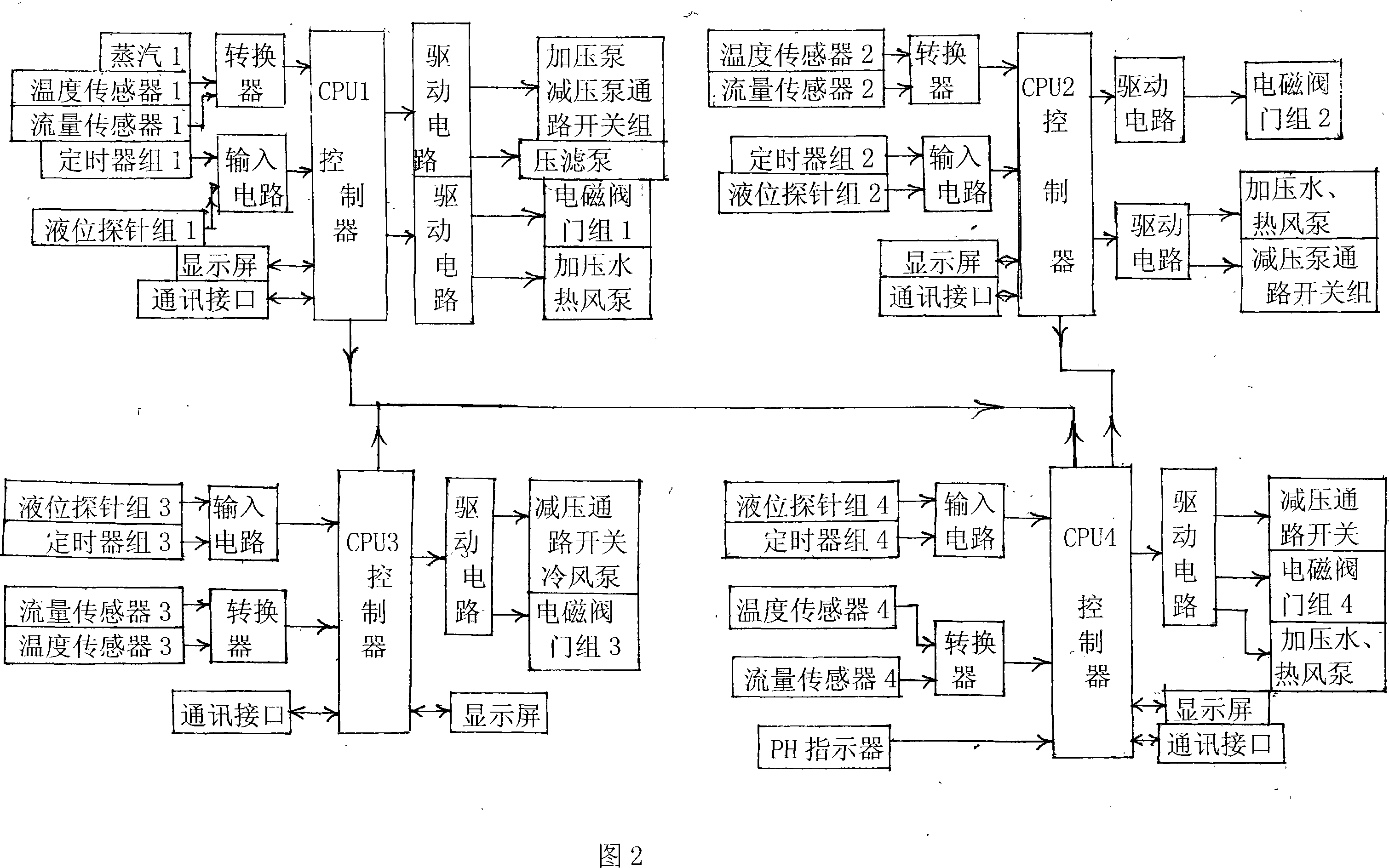

[0026] Figure 2 is a schematic diagram of the circuit structure of the controller of the present invention.

[0027] As shown in Figures 1 and 2, the present invention is set to be made up of five working areas, A area 1, 2, and 3 are raw material storage tanks, and each storage tank has a liquid level display tube with an external transparent material tube; Some are basically operated manually.

[0028]Area B a and b are reaction kettles for the production of polypeptide protein liquid. The feeding ports are evenly equipped with feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com