A high-voltage connection terminal

A high-voltage wiring and terminal technology, which is applied in connection, conductive connection, contact manufacturing, etc., can solve the problems of large structure, ablation damage of high-voltage wiring terminals, unreasonable contact of output and input terminals of transmission connections, etc., and achieve high voltage and large current And high-frequency pulse discharge transmission stable, compact structure, low inductance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

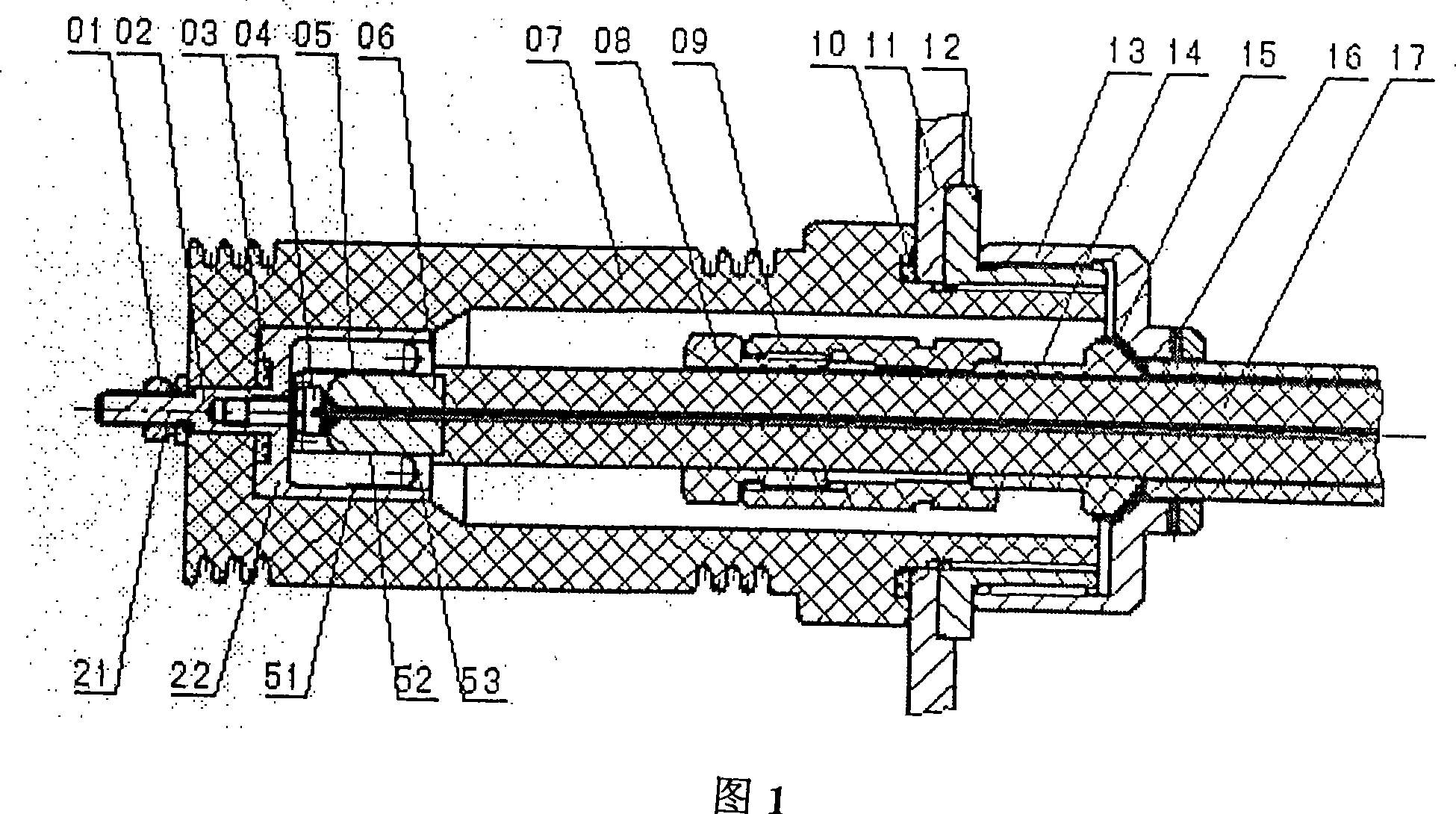

[0015] As shown in Figure 1:

[0016] The high-voltage terminal of the present invention comprises a high-voltage plug seat 02, a high-voltage plug shrapnel 05, a high-voltage plug 06, an insulating cylinder 07, and a fastening device.

[0017] The high-voltage plug socket 02 is divided into two parts: one part is a solid shaft 21 with external threads, and the solid shaft 21 protrudes from the hole at one end of the insulating cylinder 07; the other part is a cylinder 22, the cylinder 22 The bottom is connected to the solid shaft 21 and pressed against the inner surface of the insulating cylinder 07; the sealing ring 03 is used to seal the cylinder 22 and the insulating cylinder 07; the first fastening nut 01 fastens the high-voltage plug seat 02 to the insulating cylinder 07 superior. The high-voltage plug shrapnel 05 is a multi-lobe elastic double-layer cylindrical structure, and the longitudinal section of the connection 53 between the outer layer 51 and the inner layer 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com