Air ground line downward link and method for ground line assembly

A technology of overhead ground wires and ground wires, which is applied to the configuration of ground wires, etc., can solve problems such as burnout and huge losses, and achieve the effects of reliable connection, reduced operating costs, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

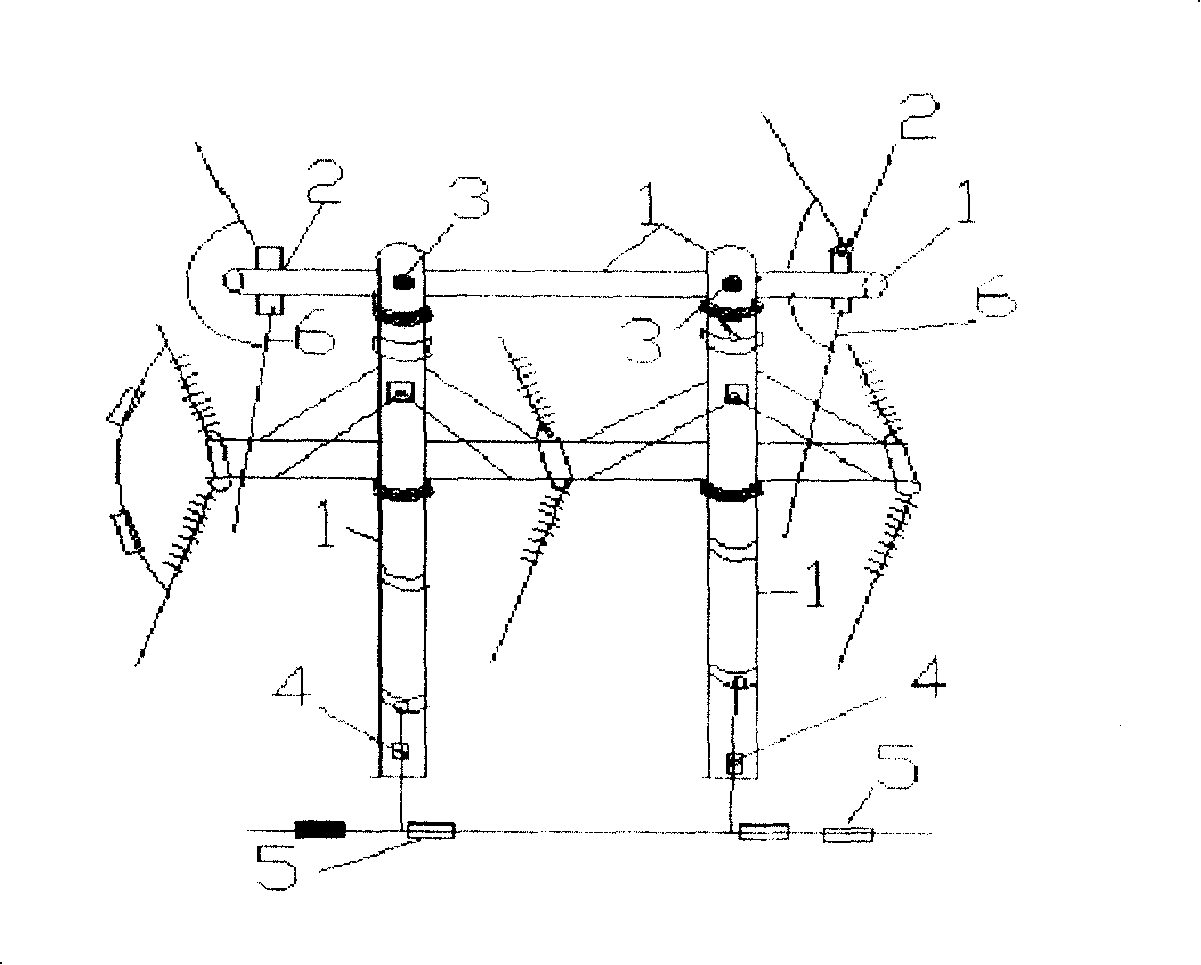

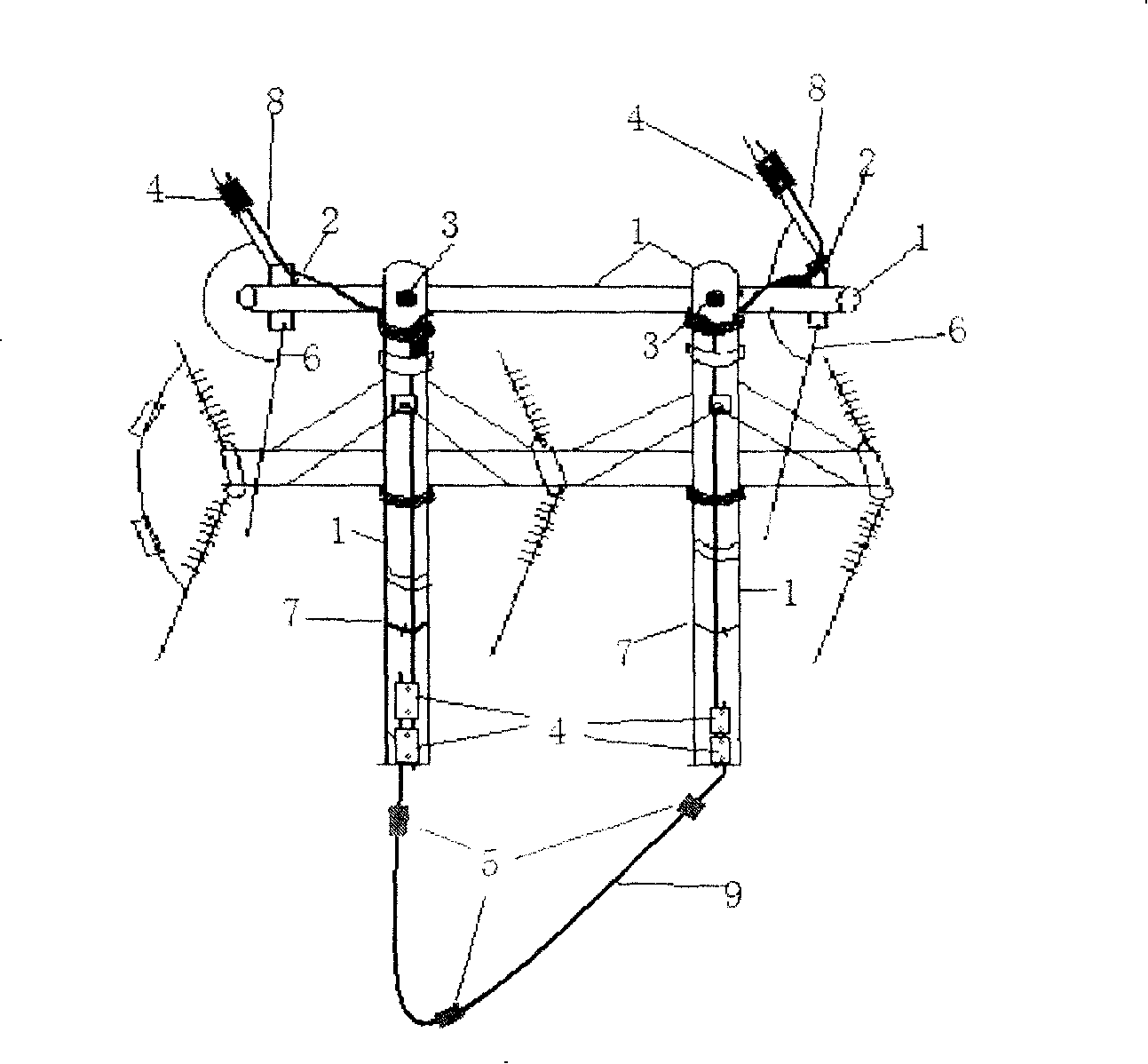

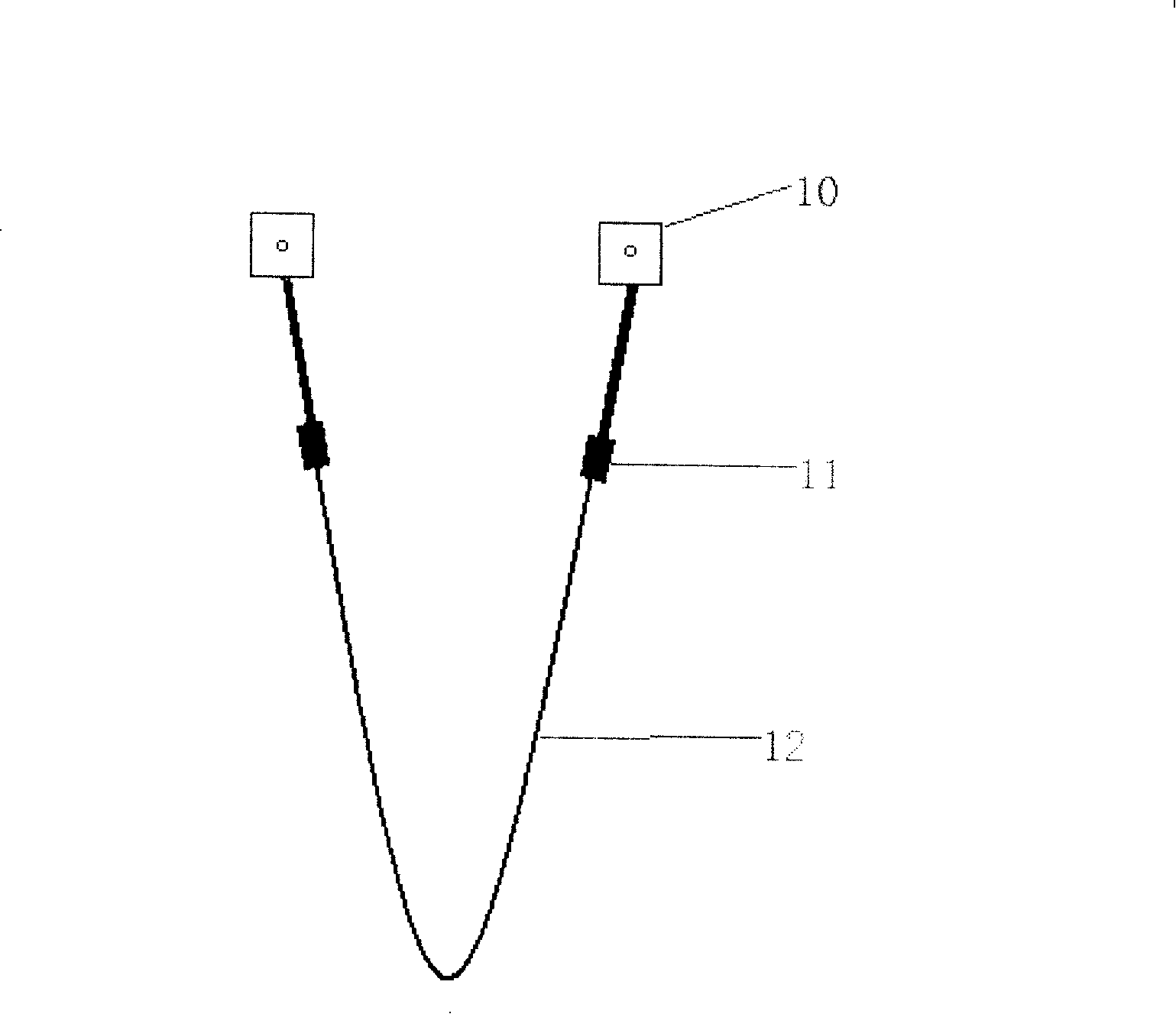

[0024] Such as figure 2 , image 3 Shown, a kind of overhead ground wire down-conducting connection of the present invention and the method for grounding wire assembly have the following specific steps:

[0025] 1) For the door-shaped pole of the cement pole, choose the material: use the GJ---35 type steel strand with the length of the pole minus one meter as the down conductor 8 of the overhead ground wire, and use the G---1 type parallel ditch clamp 4 fasten, fix the GJ---35 type steel strand on the cement rod body 1 with No. 10 iron wire 7.

[0026] 2) There are not many materials added to the newly erected lines, and the lines in operation can be operated live except for a single pole that cannot maintain safe live work. Carefully carry out construction under supervision. In order to prevent the GJ---35 steel strand from swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com