Punch and its using method

A stamping machine and punch technology, applied in the field of stamping machines, can solve the problems of substrate whitening, gold finger peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

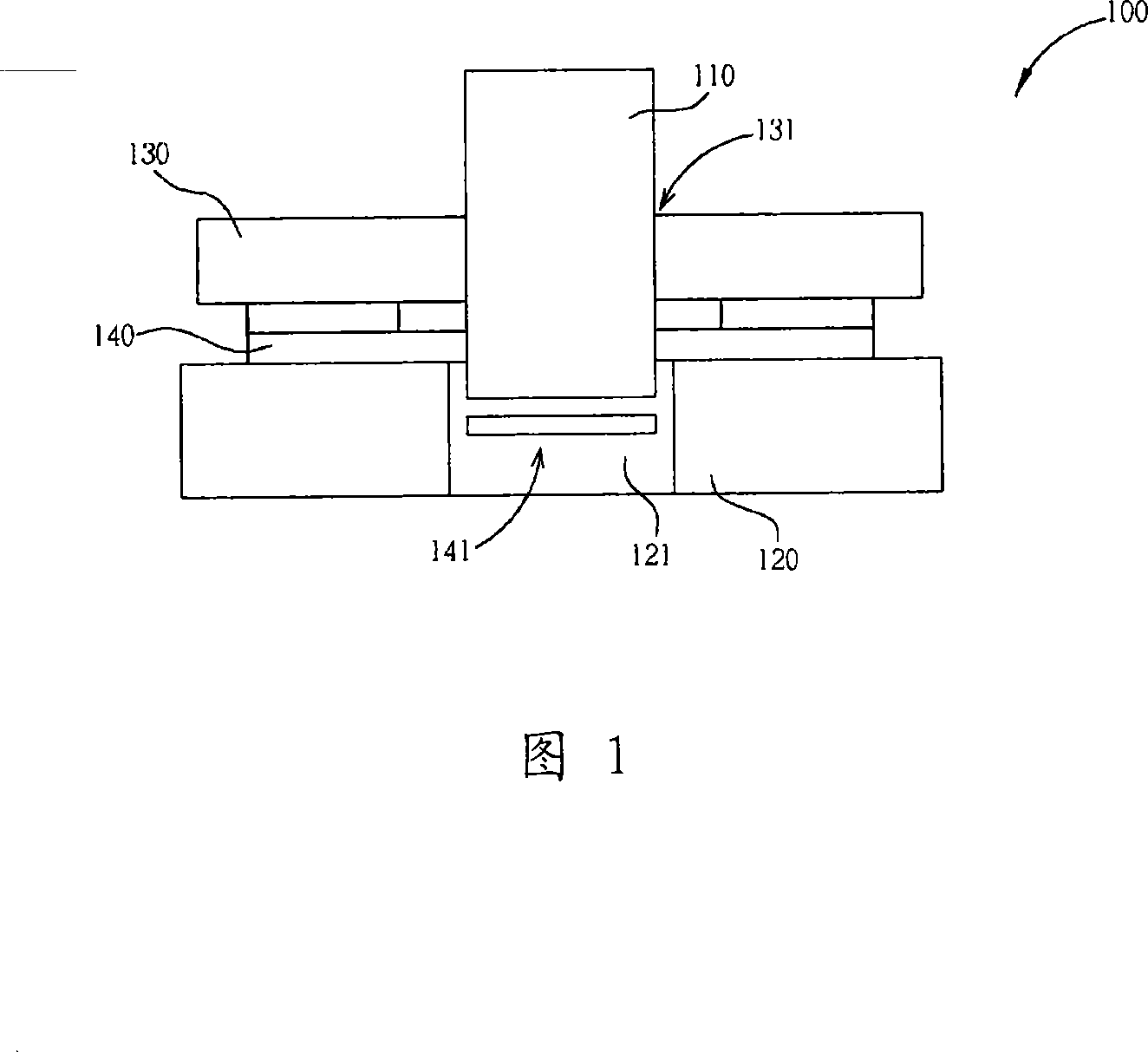

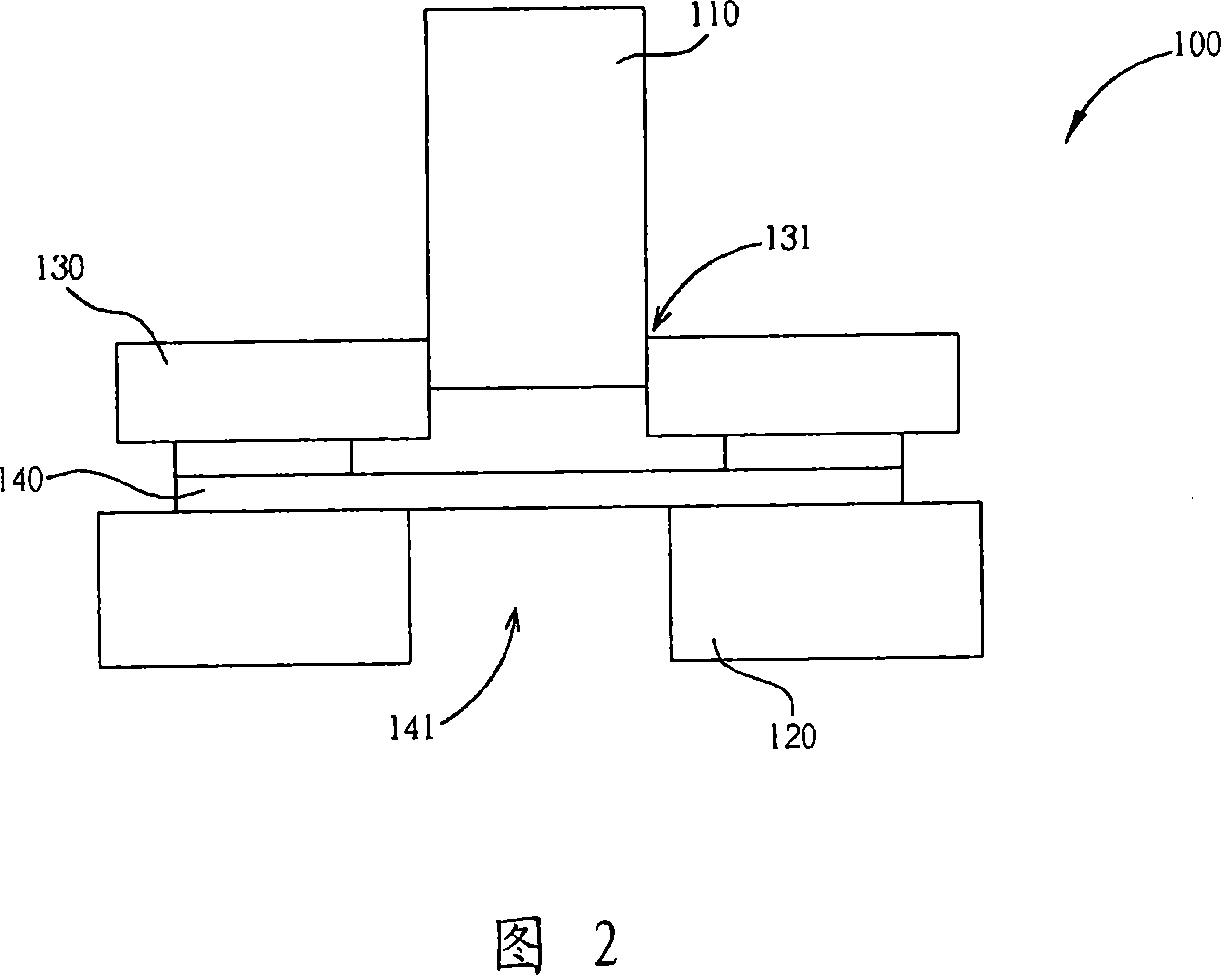

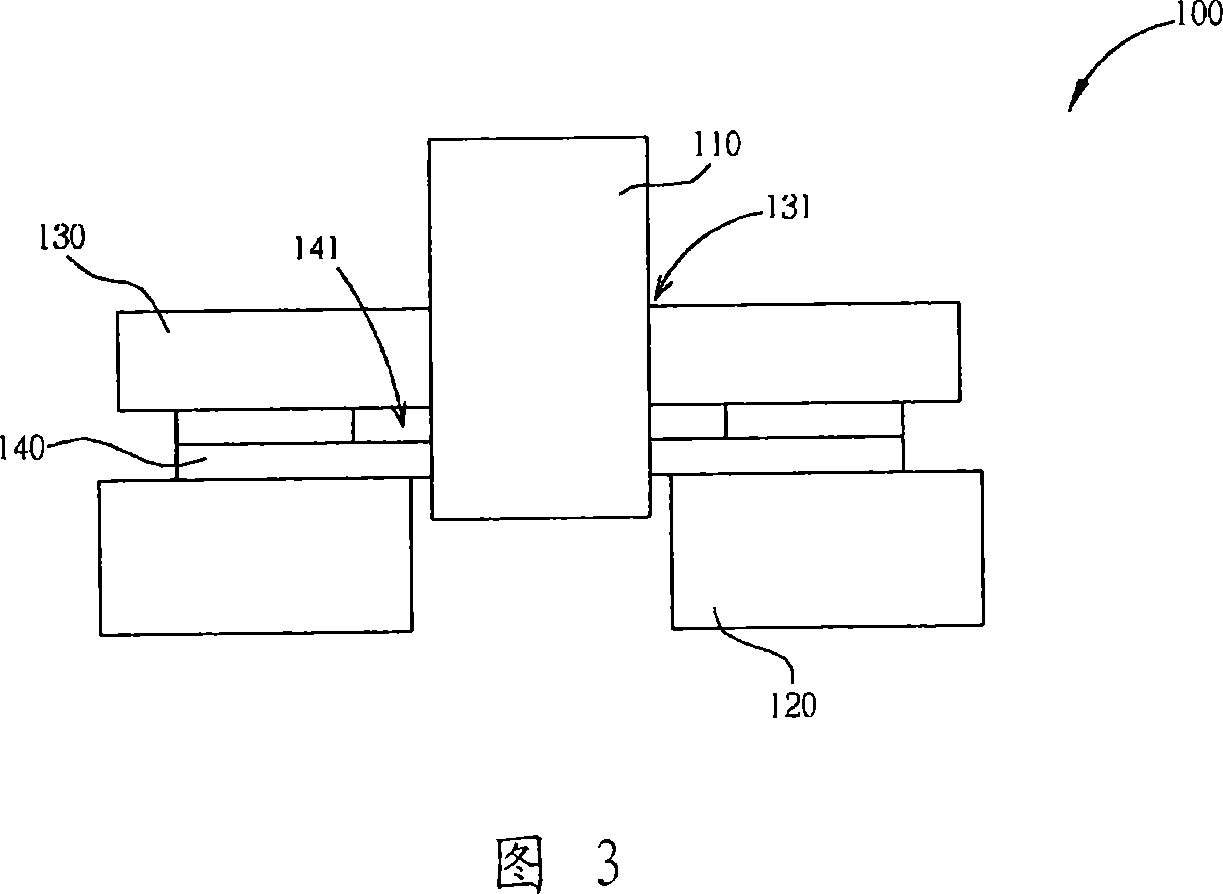

Image

Examples

Embodiment Construction

[0026] The present invention provides a novel stamping machine and its use method, which are used to solve the problems of peeling of gold fingers on the base material and whitening of the base plate when the punch moves upward in the traditional stamping machine. The punching machine of the present invention uses a gas with pressure to fix the substrate, so as to avoid peeling off of golden fingers and whitening of the substrate. The novel stamping machine of the present invention can greatly improve the yield rate and competitiveness of products.

[0027] FIG. 5 illustrates a punching machine 200 of the present invention for processing a substrate 240 , including a punch 210 , a lower die 220 and a stripping member 230 . The punch 210 is used to form a narrow hole 241 on the substrate 240 . The base material 240 can be a substrate to be stamped such as a board-on-chip (BOC). On the substrate 240 there is an area where a narrow hole 241 is to be formed and a green paint (So...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com