Sheet cutting device and sheet cutting method

A cutting device and sheet technology, which is applied in the direction of manufacturing tools, program control manipulators, chucks, etc., can solve the problems of operators touching tools and being injured, and achieve the effects of reducing danger, improving cutting ability, and easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

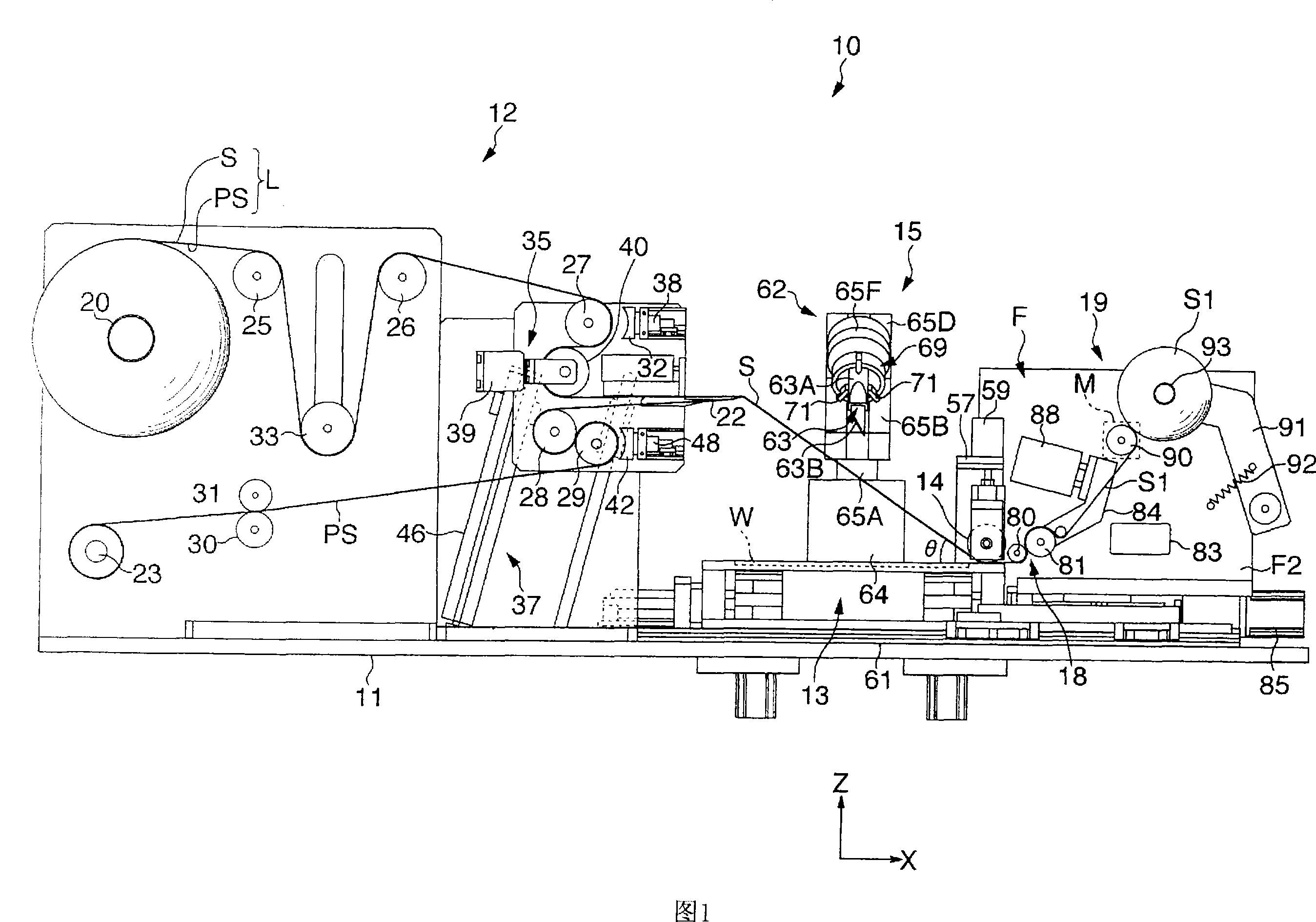

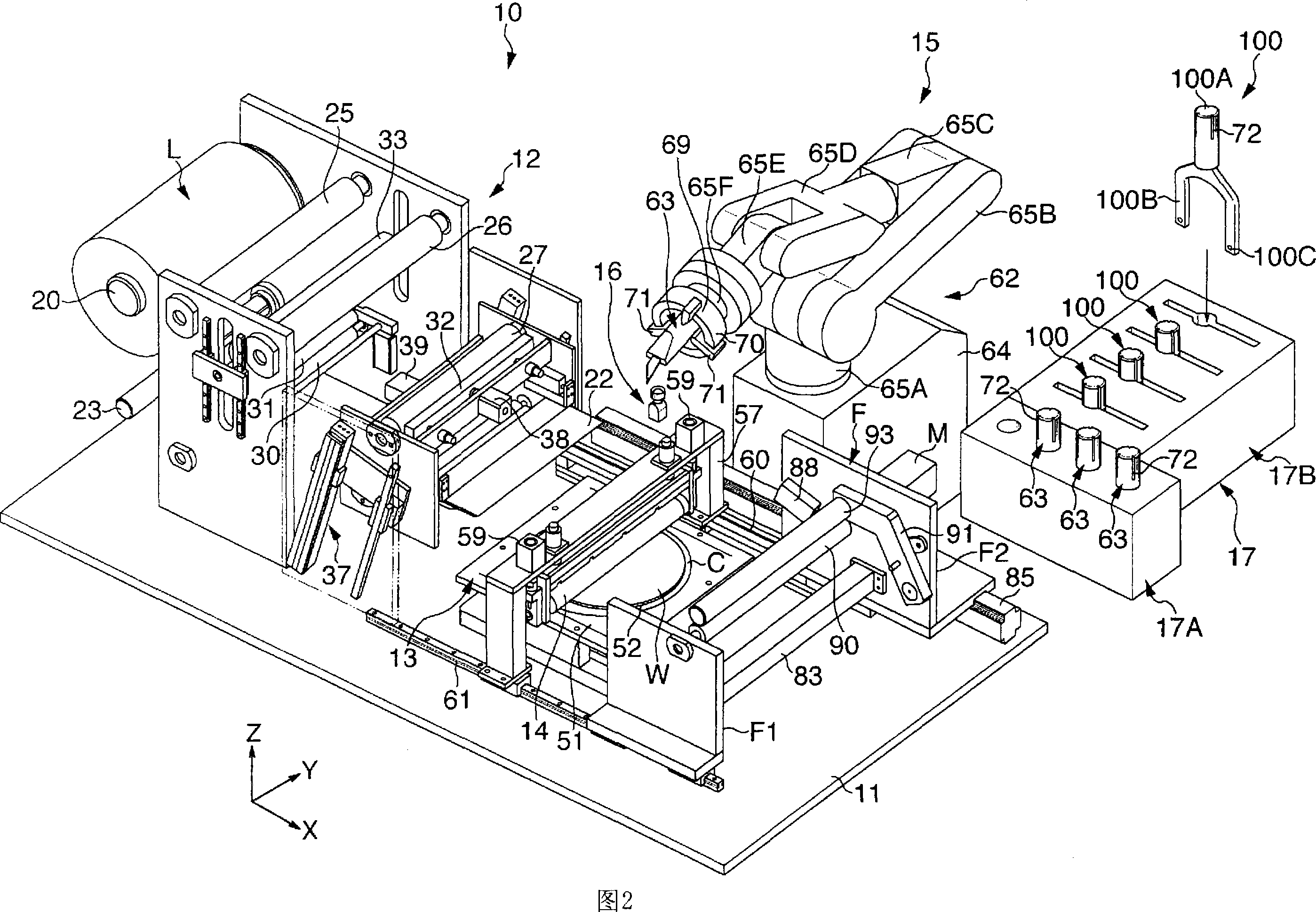

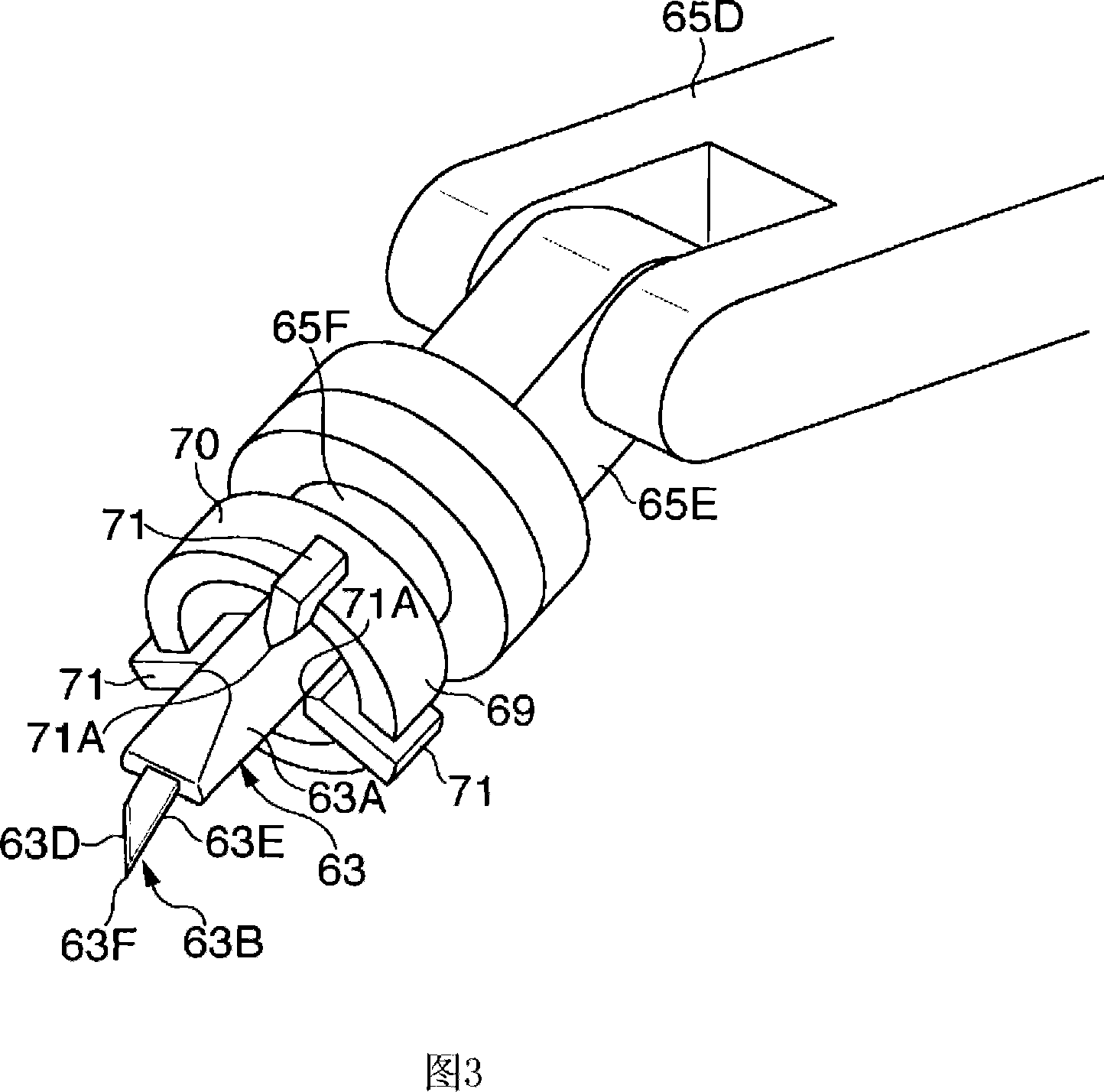

[0067] FIG. 1 is a schematic front view showing a sheet sticking device to which the cutting device according to the present embodiment is applied, and FIG. 2 is a schematic perspective view thereof. In these two figures, the composition of the sheet sticking device 10 includes: a sheet lead-out unit 12 arranged on the upper part of the base 11; a support table 13 supporting a wafer W as an object to be pasted; Adhesive sheet S, and stick it to the push roller 14 on the wafer W; after sticking the adhesive sheet S to the wafer W, a cutting device that cuts the adhesive sheet S along the outer edge of the wafer W 15; the inspection mechanism 16 (referring to FIG. 2 ) for inspecting the cutter blade 63 described later of the cutting device 15; the storage device 17 for the cutter blade 63 etc.; A peeling device 18 for peeling the upper surface; a winding device 19 for wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com