Optical fiber sensor

An optical fiber sensor and optical fiber technology, which is applied in cladding optical fiber, using optical devices to transmit sensing components, instruments, etc., can solve problems such as light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

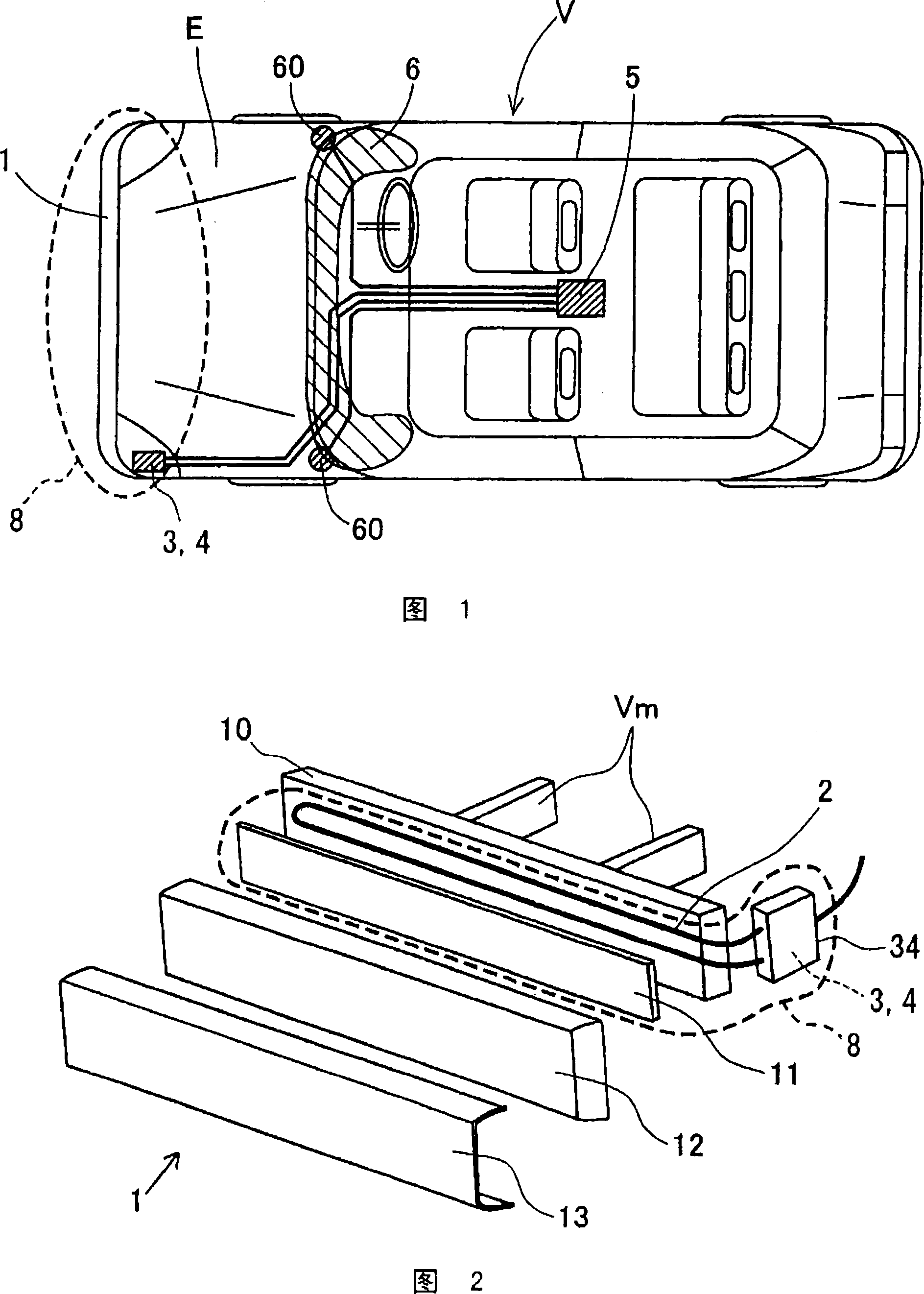

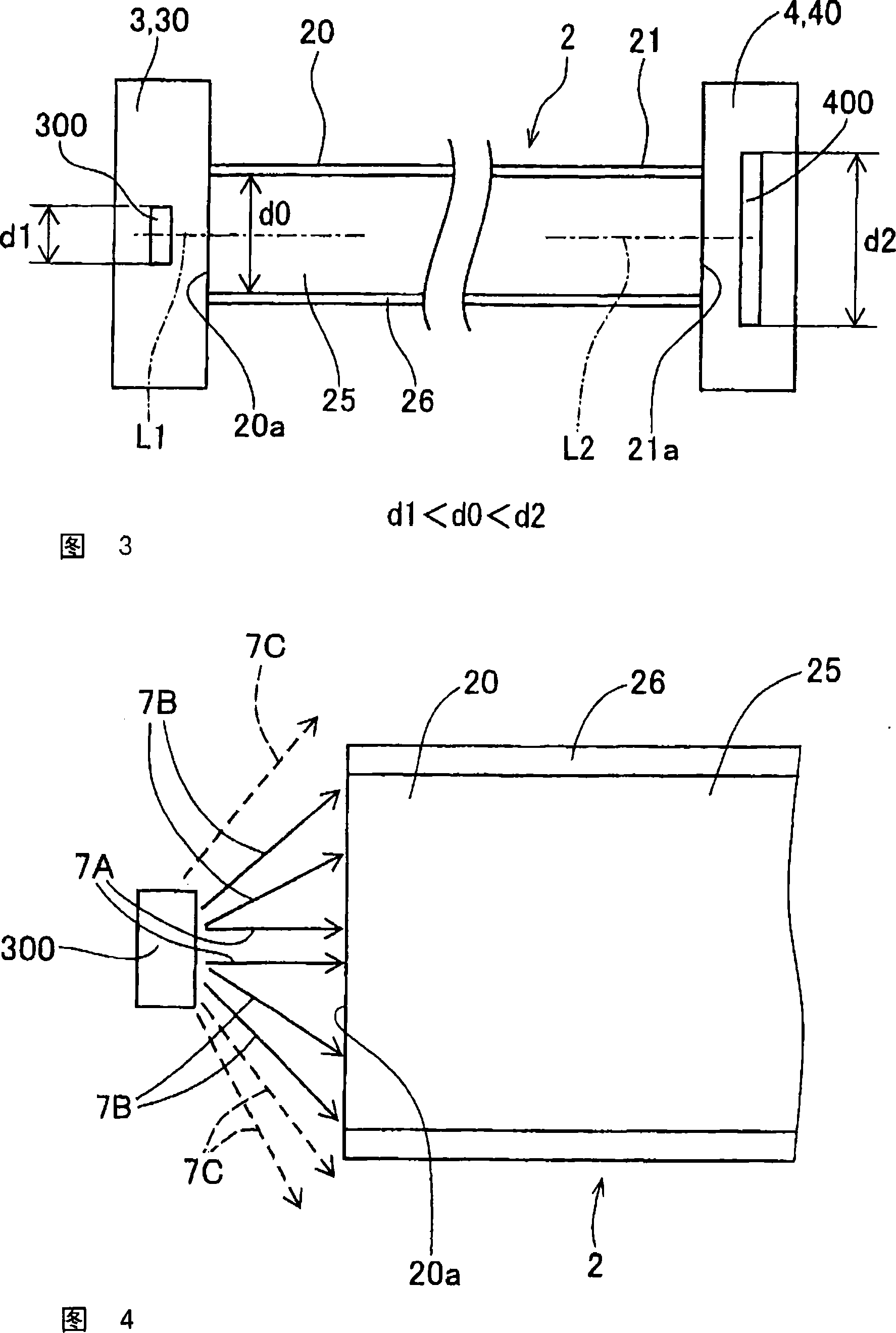

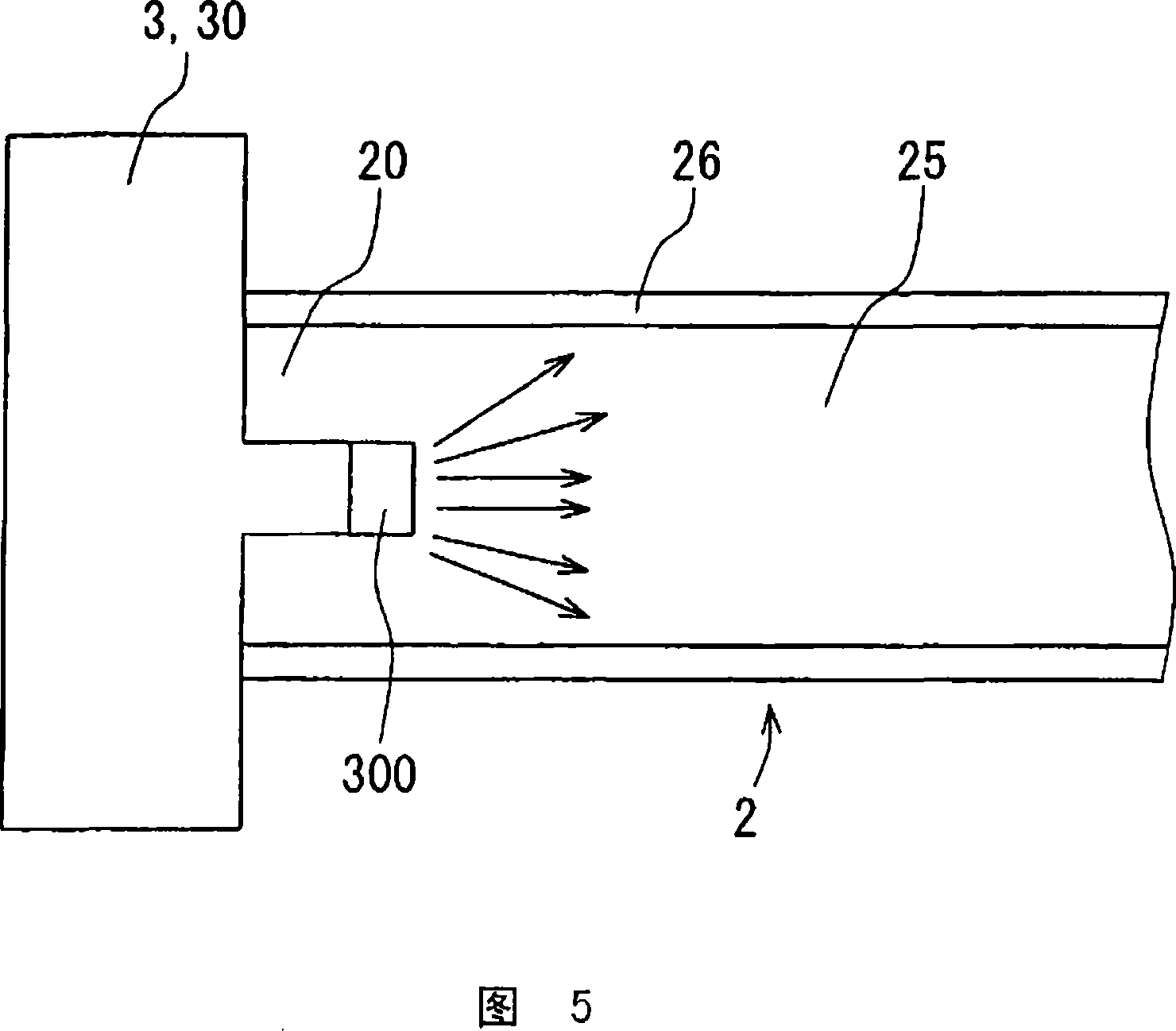

[0017] The optical fiber sensor of the present invention has an optical fiber, a light emitting member connected to a first end of the optical fiber, and a light receiving member connected to a second end of the optical fiber. The light emitting member emits light toward the first end of the optical fiber. Light is transmitted from the first end to the second end in the optical fiber, and is irradiated toward the light receiving member from the second end. Fiber optic sensors determine changes in light that occur when light passes through an optical fiber based on characteristics of light emitted from a light emitting member such as intensity and phase and characteristics of light received in a light receiving member. In addition, the fiber optic sensor calculates the stress applied to the fiber based on the change in light.

[0018] When stress is applied to the fiber, the fiber deforms and the light transfer characteristics change at the deformed portion of the fiber. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com