Space three-rotation freedom parallel mechanism

A technology with three rotations and degrees of freedom, applied in the field of robotics, can solve the problems of increasing the quality of the kinematic chain and unfavorable high-speed movement of the mechanism, and achieve the effect of easy high-speed movement, good dynamic characteristics of the mechanism, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

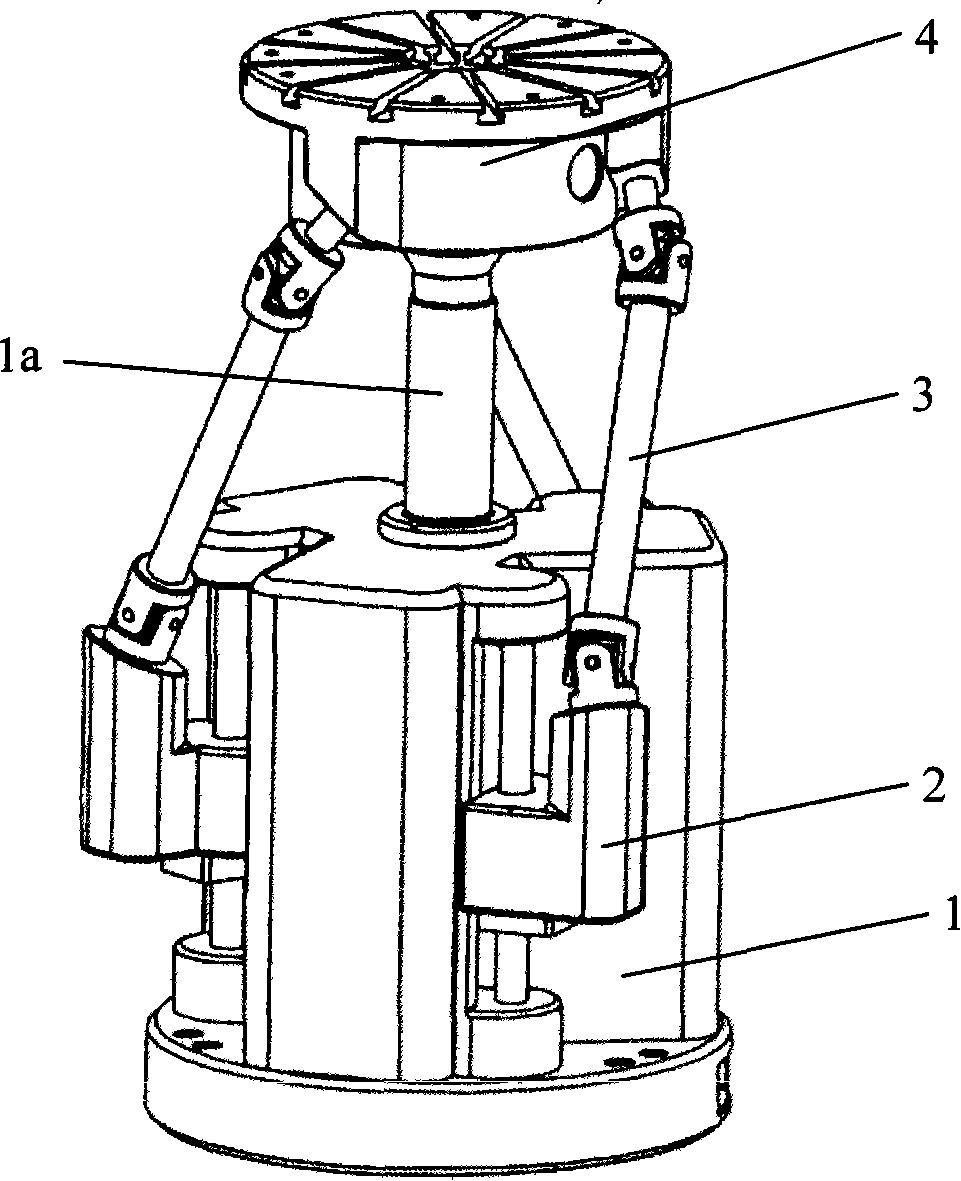

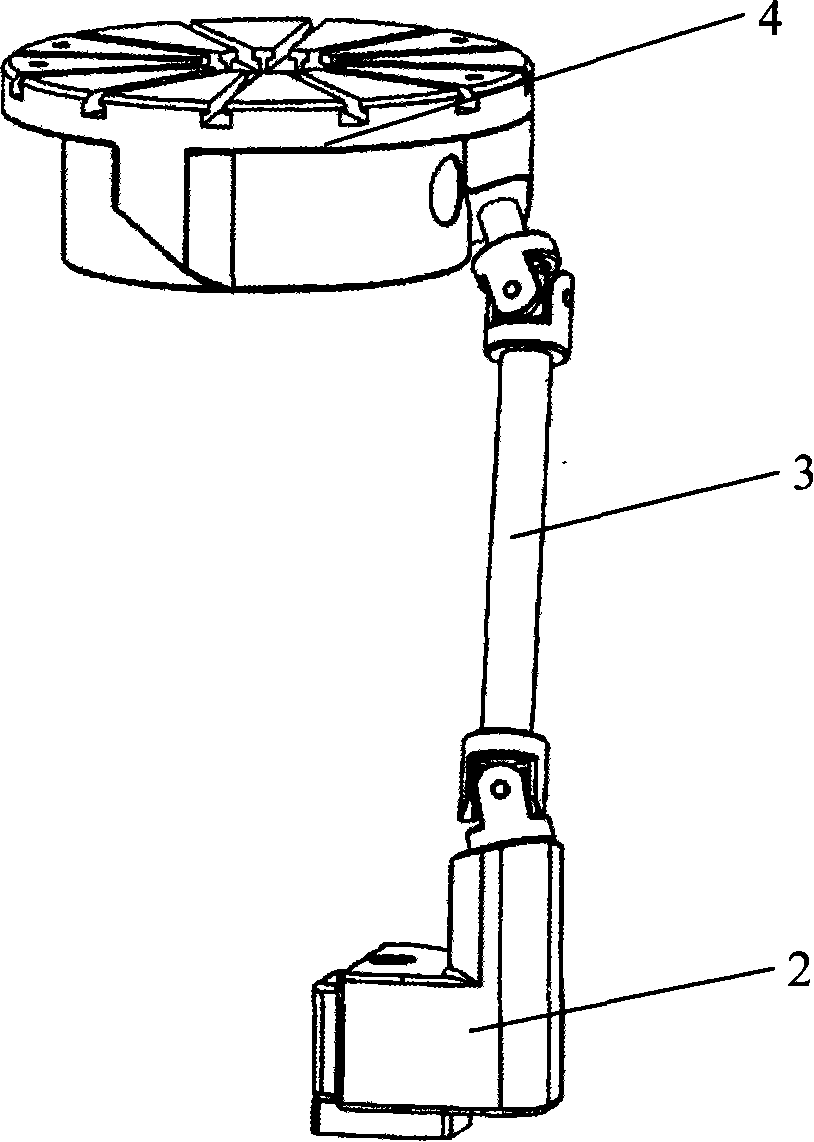

[0012] Such as figure 1 and figure 2 As shown, the present invention is a parallel mechanism with three rotational degrees of freedom in space. The fixed frame 1, the movable platform 4 that is ball-hinged with the bracket 1a on the fixed frame, and the fixed frame 1 and the movable platform 4 are respectively axisymmetrically and evenly arranged on the fixed frame 1 and the movable platform 4. The three kinematic branch chains with the same structure are formed; the three kinematic branch chains are composed of sliders 2 and connecting rods 3 respectively, and adopt the form of external drive, and the driving device is installed on the fixed frame 1. The connection between the moving platform 4 and the fixed frame 1 is as follows: the moving platform 4 is connected to the end of the bracket 1a fixed on the fixed frame 1 by using a ball joint. There are two ways to conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com