Front window shield for vehicle

A vehicle and front window technology is applied in the field of vehicle front windows, which can solve the problems of inability to reduce the burden of assembling operators, large number of parts, high cost, etc., and achieve the effect of simple and inexpensive structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

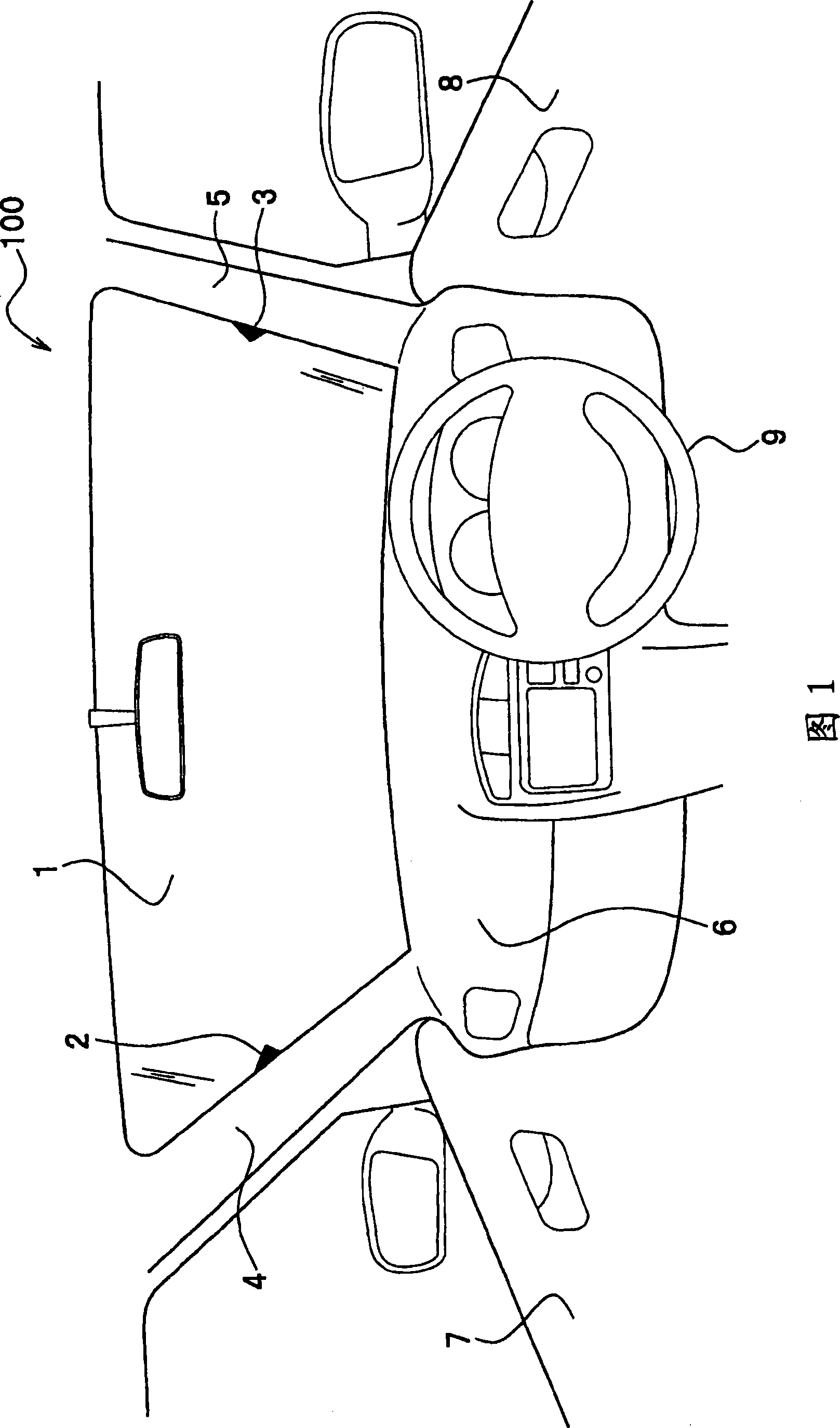

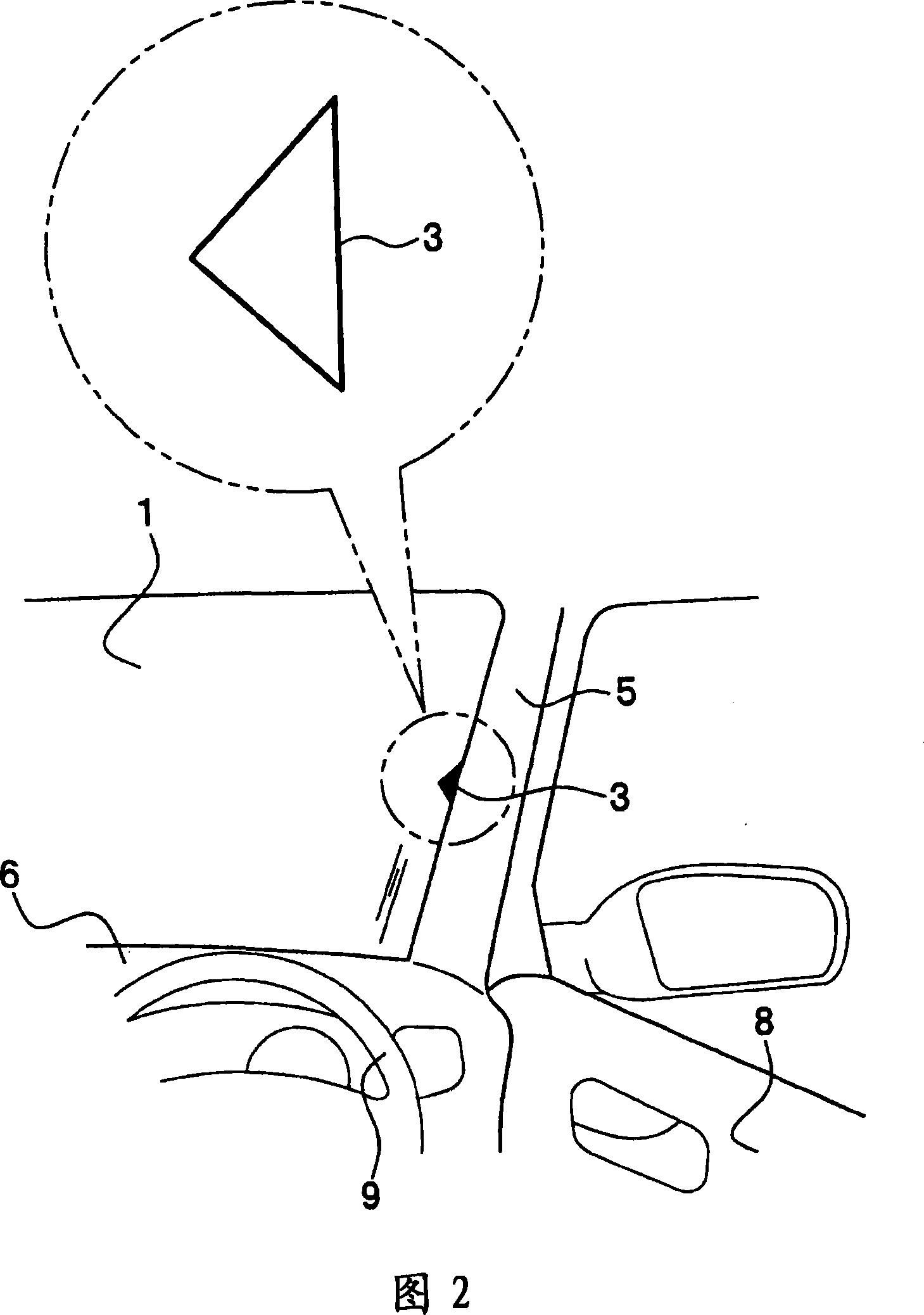

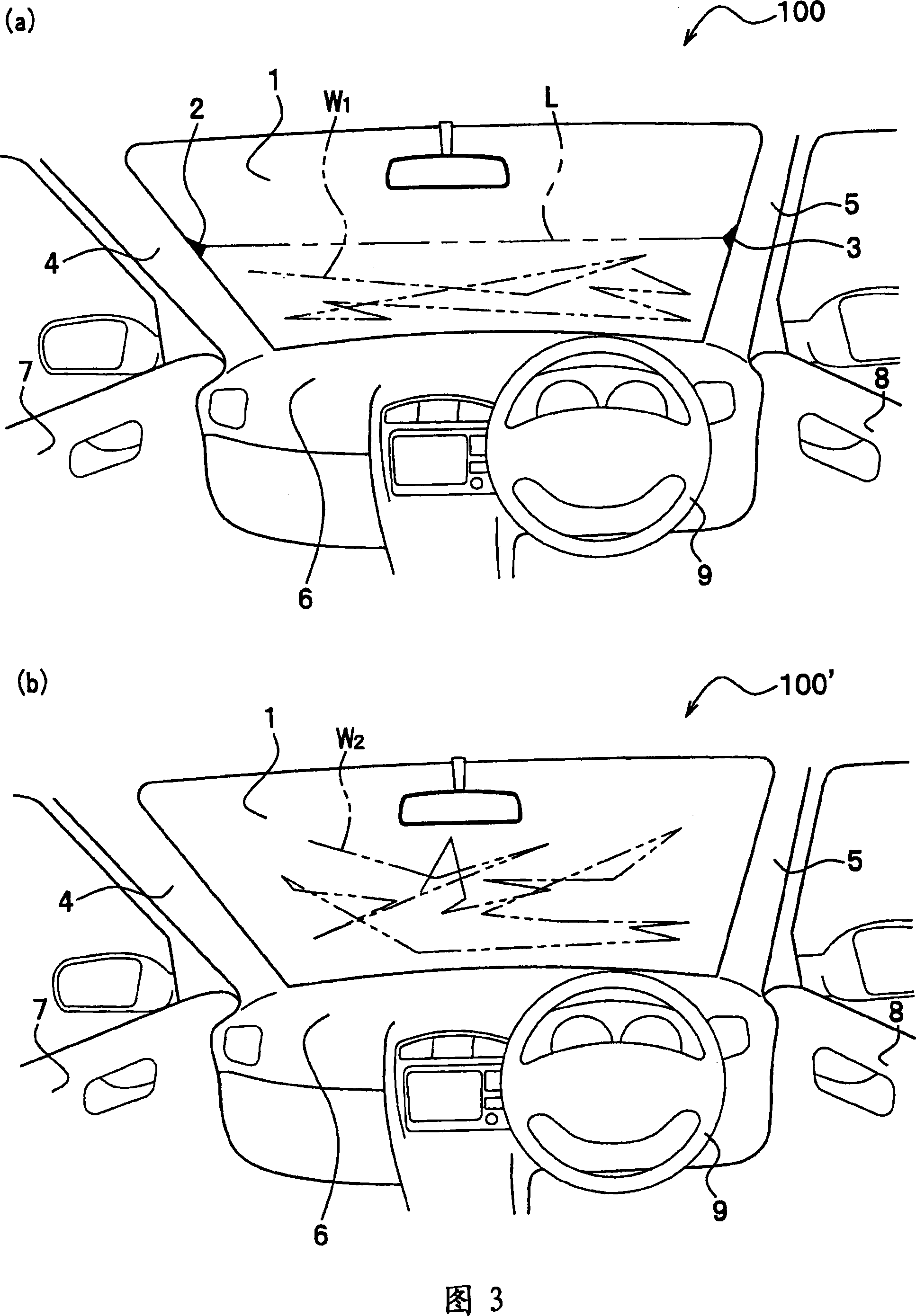

[0056] First, refer to figure 1 The schematic diagram shown is for explaining the vehicle windshield of the first embodiment. That is, the case where the vehicle comes into contact with a horizontal road surface will be described here.

[0057] Such as figure 1 As shown, in this vehicle 100 , a pair of marks 2 and 3 showing a substantially horizontal direction are provided on a vehicle front window (hereinafter referred to as "front window") 1 . The marks 2 and 3 are formed at the same height positions on the left and right sides of the front window 1 . Accordingly, the driver can perceive an imaginary straight line connecting the pair of marks 2 and 3 .

[0058] The markings 2, 3 are formed of so-called black ceramic prints (hereinafter referred to as "black porcelain"). Therefore, when black porcelain is formed on the edge of the glass of the front window 1 etc., the marks 2 and 3 may be formed on the front window 1 by making a part of it into a pair of isosceles trian...

Embodiment approach 2

[0089] Next, refer to Figure 8 The schematic diagram shown is for explaining the front window of Embodiment 2. FIG. and, in Figure 8 In, symbols 1, 4, 5, 6, 7, 8, 9 and figure 1 All parts shown are the same. In this vehicle 300 , regions 1 a , 1 b having lower transmittance than the high transmittance region of the windshield 1 are formed at the center of the upper and lower portions of the windshield 1 . Therefore, the regions with high transmittance other than the regions 1a and 1b with low transmittance are formed in a substantially H-shape.

[0090] Furthermore, the difference in transmittance between the high region and the low region may be any different ratio as long as the two can be distinguished. Furthermore, the regions 1a and 1b may be formed so that the transmittance changes when viewed from the driver's seat side (here, the right side). The regions 1 a and 1 b are formed by sandblasting the front window 1 , but they are not limited to this as long as the ...

Embodiment approach 3

[0098] Next, refer to Figure 9 The schematic diagram shown is for explaining the vehicle windshield of Embodiment 3. FIG. and, in Figure 9 In, symbols 1, 4, 5, 6, 7, 8, 9 and figure 1All parts shown are the same. In this vehicle 400 , when viewed from the driver's seat, the lower edge portion B of the windshield 1 has a substantially horizontal straight line shape, and the left end of the lower edge portion B intersects the horizontal waistline A on the left front pillar 4 . , the right end of its lower edge portion B crosses with the horizontal waistline C on the right front post 5 . That is, the lower end edge B and the waistlines A and C are at the same height.

[0099] The lower end edge B is formed in a substantially horizontal curved shape, and is formed of black porcelain (edge auxiliary body) 1c formed in a substantially horizontal linear shape visually viewed from the driver's seat. Since the front window 1 is formed in a curved shape protruding forward, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com