Fuel injection device for I.C. engine

A technology for a fuel injection device and an internal combustion engine, which is applied to a fuel injection device, a fuel injection device with an oil accumulator, a combustion engine, etc., can solve problems such as time-consuming, and achieve the effect of stabilizing the switching time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

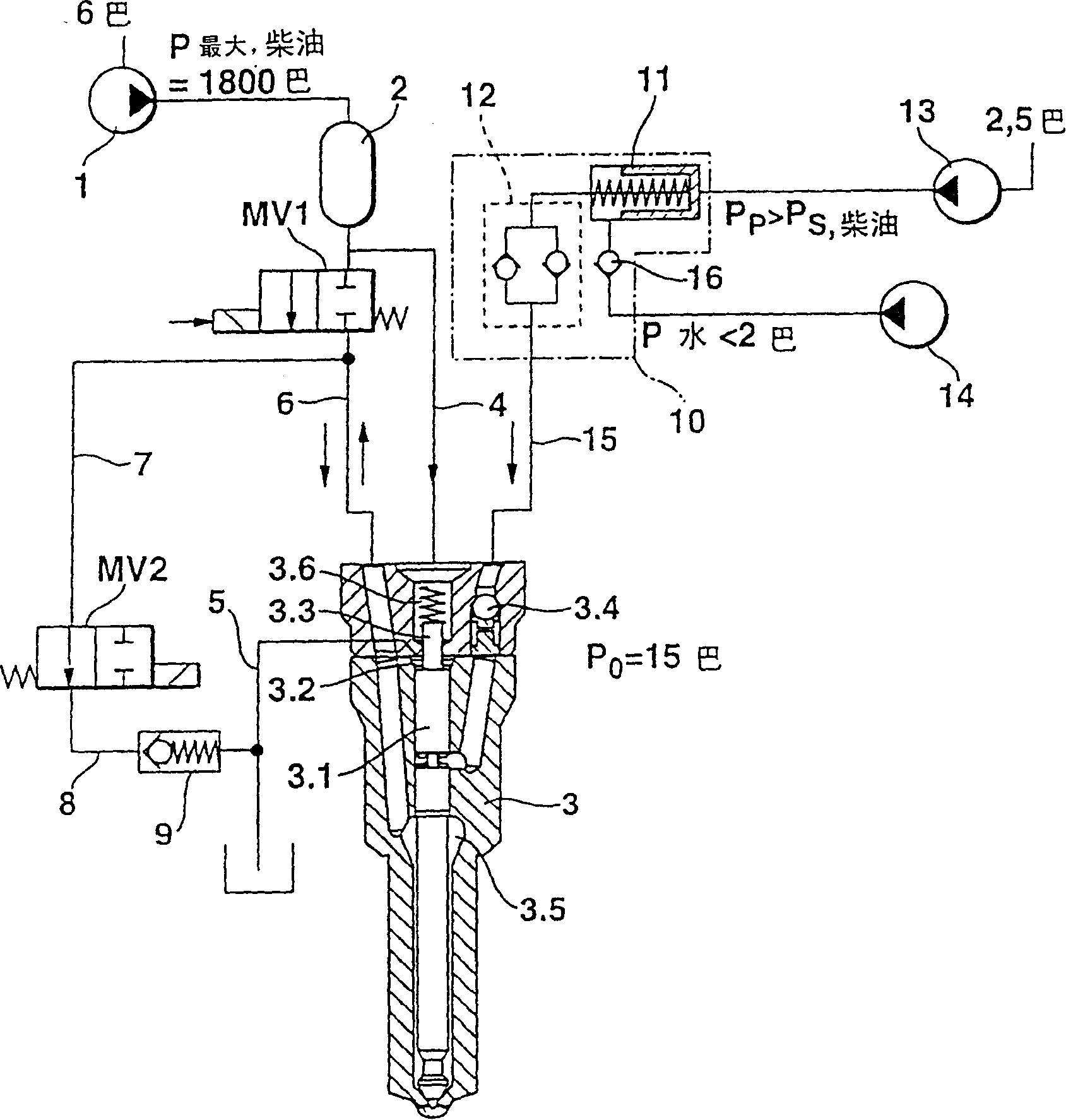

[0019] exist figure 1 In the shown first embodiment of the internal combustion engine fuel injection device for injecting fuel (usually diesel oil) and an additive liquid (usually water) two-fluid according to the present invention, a high-pressure pump 1 feeds the common rail-accumulator Unit 2 supplies fuel at a pressure level of approximately 1800 bar. Because the previously conventionally used fuel injection pump is replaced by a combination of the common rail-accumulator 2 and a simple high-pressure pump 1 and there is always a certain level of rail-pressure, now, in the common rail-accumulator 2 A dosing element must be installed between the pressure accumulator and the pressure chamber 3.5 surrounding the injection needle 3.1 of the double-material nozzle 3, which is supplied with fuel from the pressure accumulator via an injection line 6. In the configuration of the invention, a first 2 / 2-way valve MV1 takes over this task. The valve should be designed as a fast sole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com