Semi-automatic hydraulic wall board conveying upending vehicle

A semi-automatic, hydraulic technology, applied in the direction of construction, building structure, building materials, etc., can solve the problems of low work efficiency, difficult erection of wall panels, high labor intensity, etc., to reduce labor intensity, convenient loading and unloading, and easy operation and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

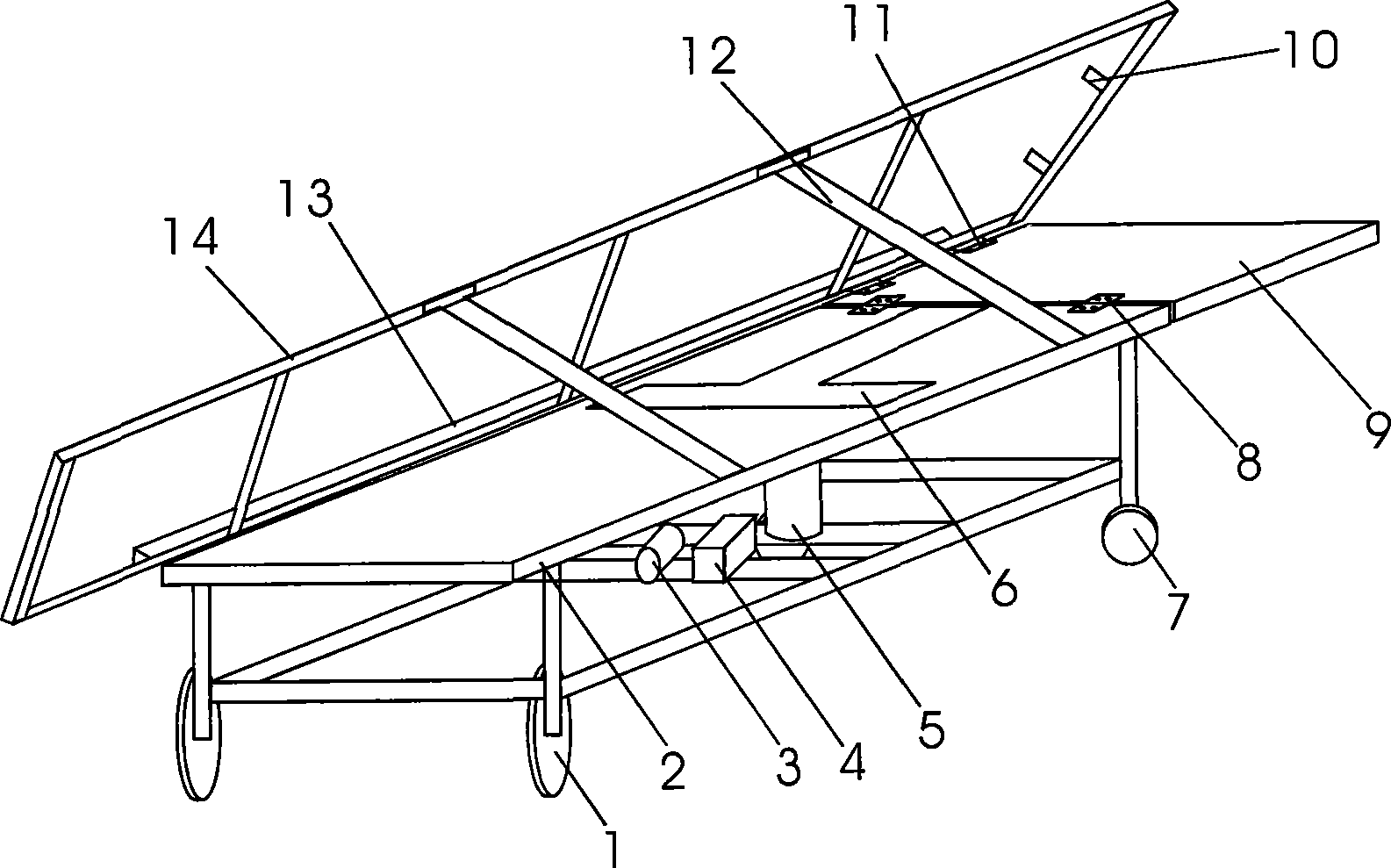

[0007] Now refer to the attached figure 1 , described as follows in conjunction with the embodiment: The semi-automatic hydraulic wallboard handling vertical vehicle according to the present invention relates to a directional rear ground wheel 1, a hydraulic oil pump 2, a power machine 3, a hydraulic jack 4, a vehicle frame, a universal front ground wheel 6, a transverse Hinge 7, forward slope plate 8, front baffle plate 9, longitudinal hinge 10, erect top plate 11, side stand pole 12, side baffle plate 13 and supporting plate 14 form. The vehicle frame 5 is the main part of the semi-automatic hydraulic wall panel handling and erecting vehicle of the present invention, which is a frame structure as a whole and is welded by angle steel or round steel. The rear grounding support point of the vehicle frame 5 is provided with a directional rear ground wheel 1 , and the front grounding support point of the vehicle frame 5 is provided with a universal front ground wheel 6 . In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com