Method for measuring surface deformation under action of metal interconnection line force/electricity coupling

A technology of metal interconnection and surface deformation, applied in the direction of measuring devices, optical devices, image data processing, etc., can solve the problems of complex optical systems, difficult to apply, easy to damage probes, etc., to achieve convenient data processing and spatial positioning Convenient and fast production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

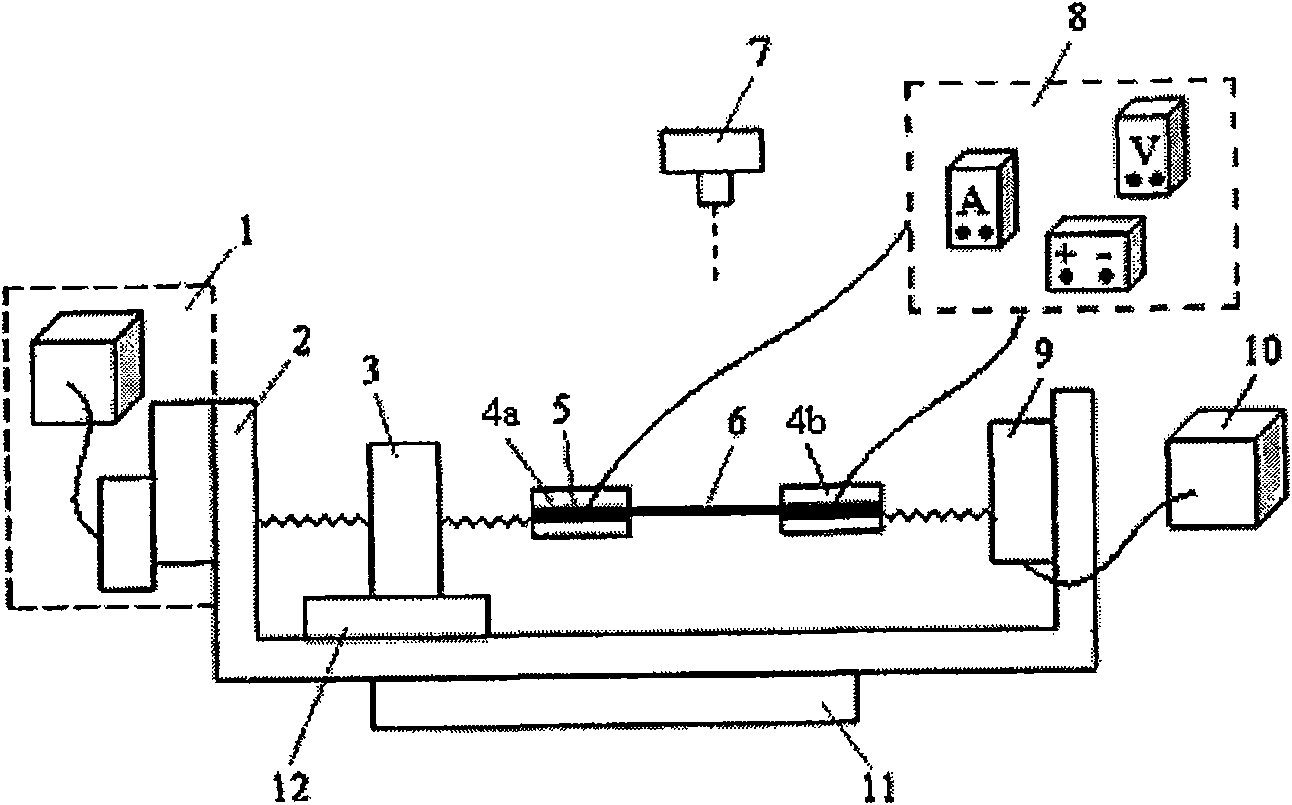

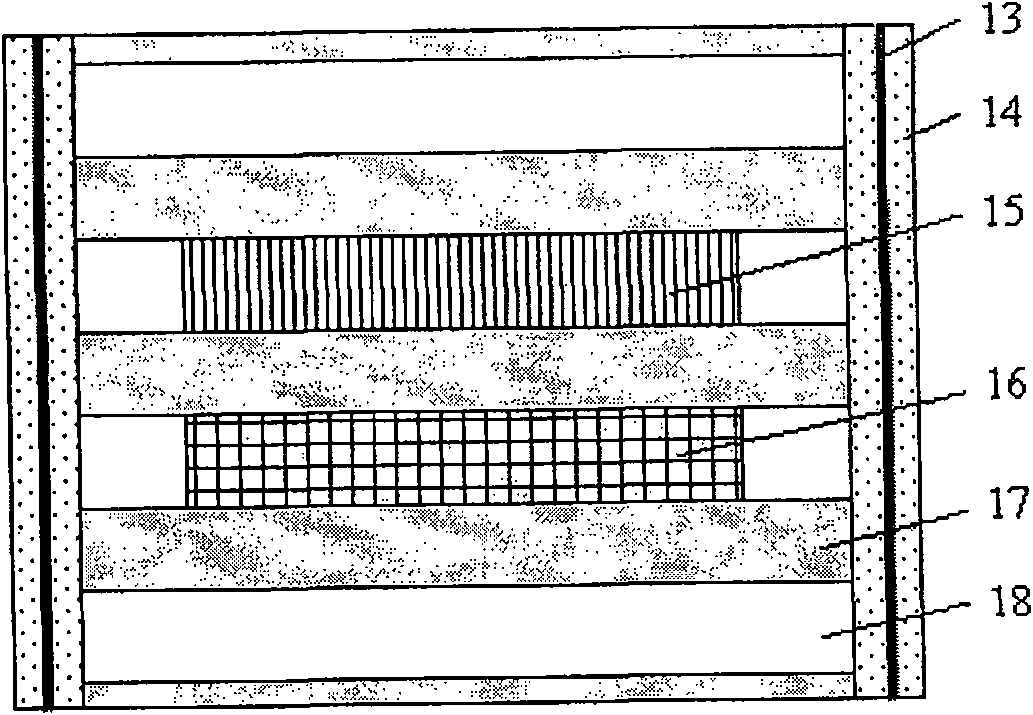

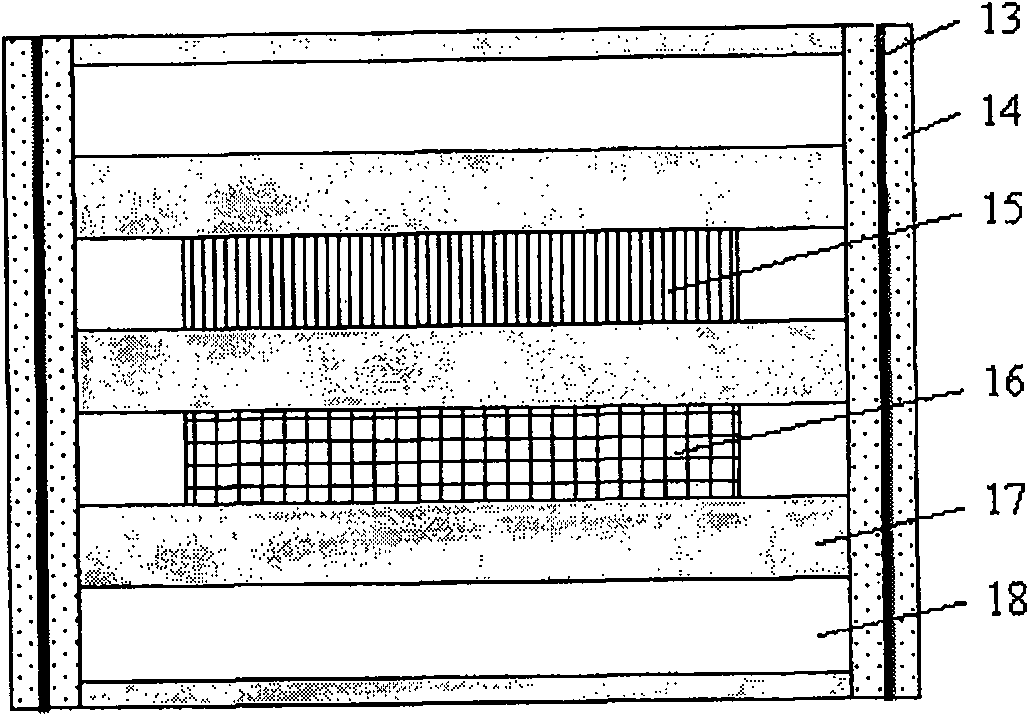

[0026] Take a sample of A1 interconnection line deposited on polyethylamide flexible substrate, the thickness of A1 interconnection line is 1 μm, the width is 8 μm, and the distance between the centers of adjacent A1 interconnection lines is 16 μm, and the sample is processed into a dumbbell-shaped pulley. Stretch the shape of the sample, the length direction of the sample is parallel to the length direction of the A1 interconnection line, the effective working area is 8mm×4mm, and 250 A1 lines are distributed in the working area, and the conductive silver glue is applied to both sides of the working area along the width direction. The two ends of these A1 lines are respectively connected to form a parallel distribution, and at the same time, two thin wires are connected from the area coated with conductive silver glue. Select two A1 interconnection wires from the sample, and use a focused ion beam microscope to fabricate orthogonal gratings with frequencies of 200l / mm and 1000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com