Steam sterilizing system and sterilizing and cooling method thereof

A steam sterilization and steam technology, applied in heating and other directions, can solve the problems of long sterilization time, long cooling time, bacterial contamination of the sterilization tank, etc., to improve the sterilization effect, reduce the sterilization time, and avoid the dead corner of sterilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

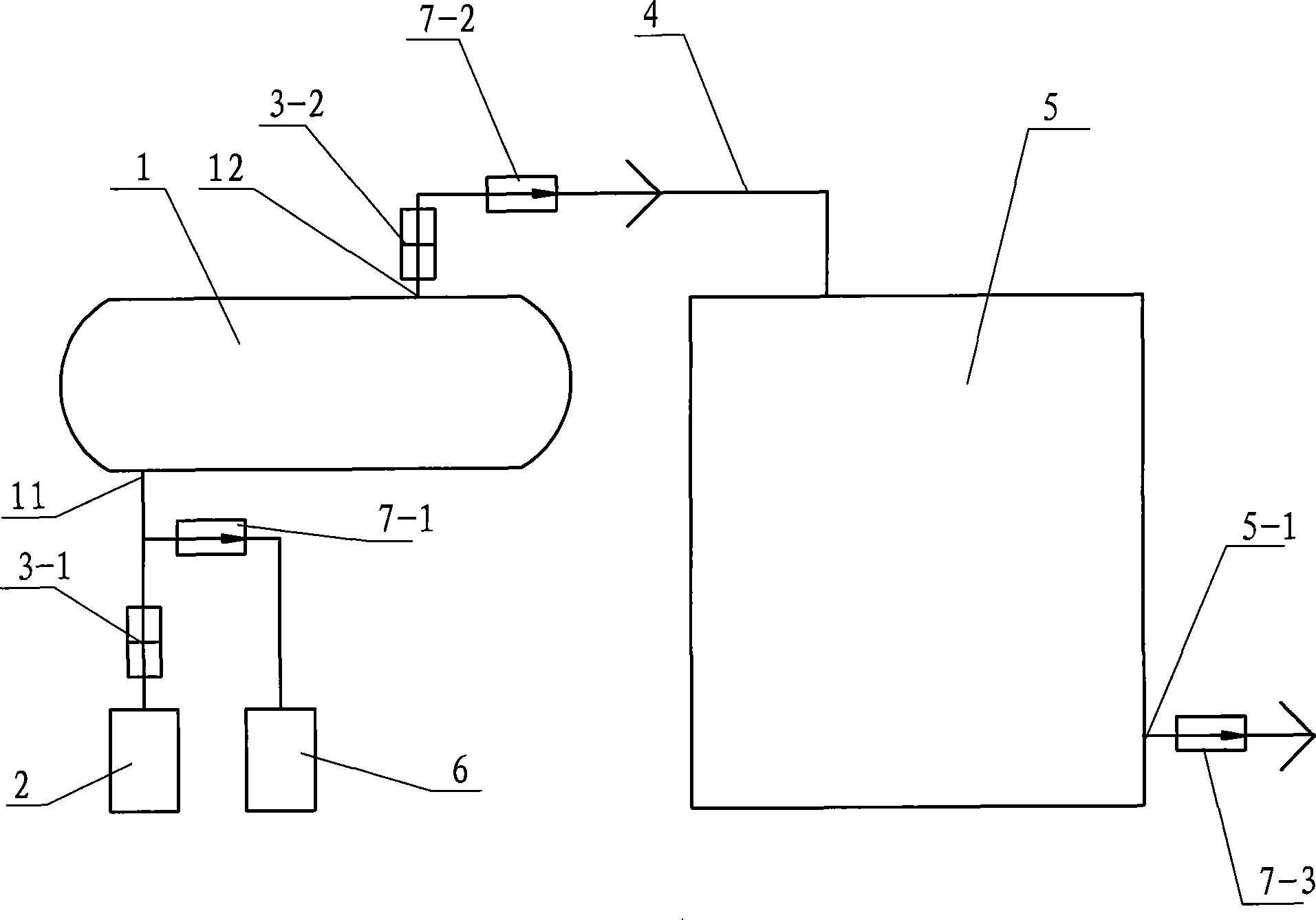

[0013] As shown in the figure, the embodiment of the sterilization system of the present invention includes a steam sterilizer 1 that can be fed with high-temperature steam. The steam sterilizer has a conventional steam inlet and a steam exhaust port, and also has an air inlet 11 and An air outlet 12, an air pump 2 is connected to the air inlet 11 through an air filter 3-1, and the air outlet 12 leads to a sterile space 5 through a section of air transmission pipeline 4, which can be a sterile culture room , Aseptic inoculation room and other necessary aseptic environment in the fermentation production process. In addition, the system also includes a vacuum pump 6, which is connected to the air inlet 11 on the steam sterilization tank through a check valve 7-1, so that the air inlet can be used as a suction port during the vacuuming process.

[0014] In order to further prevent recontamination in the steam sterilization tank, an air filter 3-2 and a check valve 7-2 are also ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com