Supporting leg longitudinal seam automatic welding machine

An automatic welding machine and longitudinal seam technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reducing product manufacturing precision and product quality, cumbersome steps, poor welding effect, etc., to solve the problem of manpower A lot of resources are wasted, the structure design is reasonable, and the product quality is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

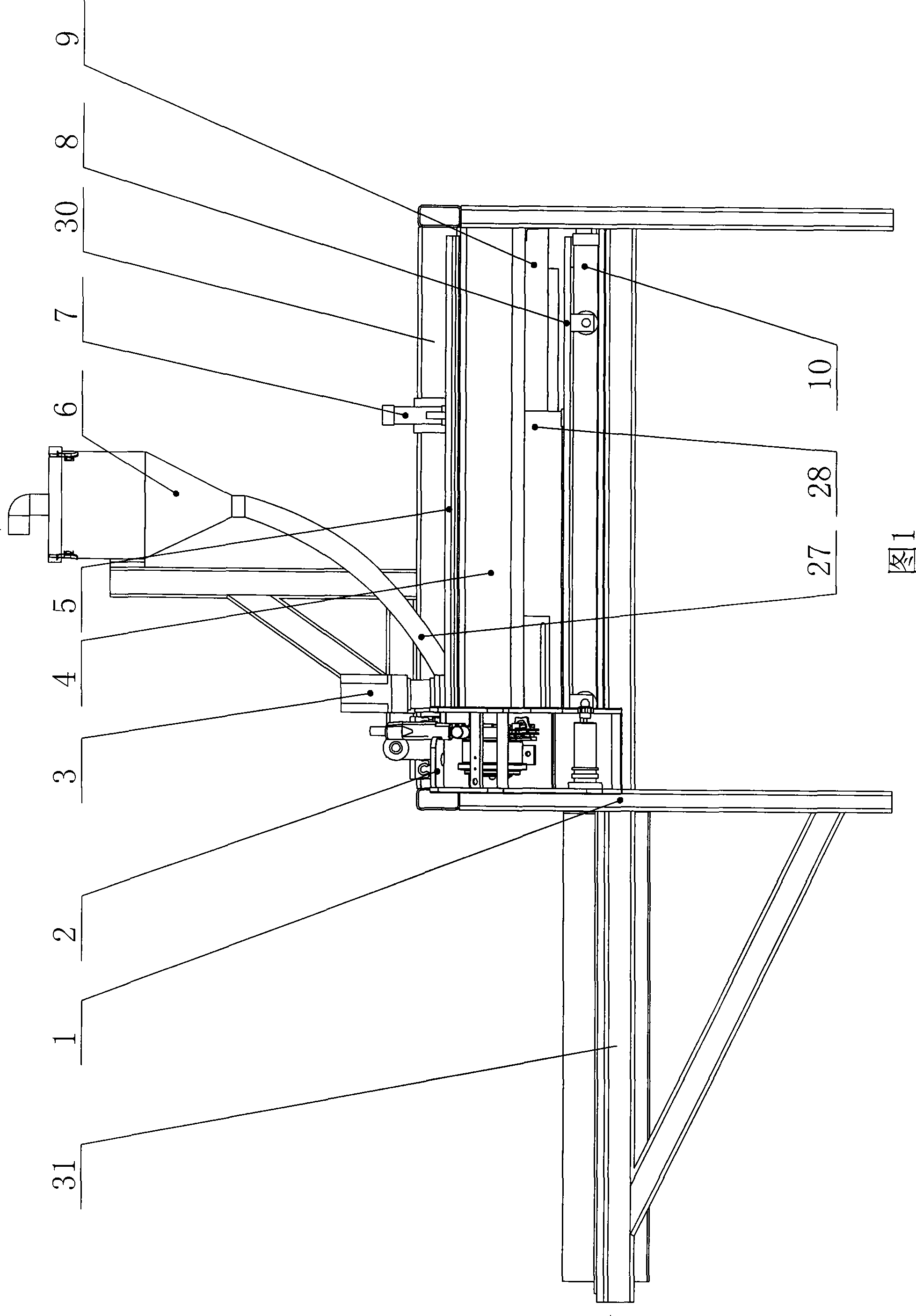

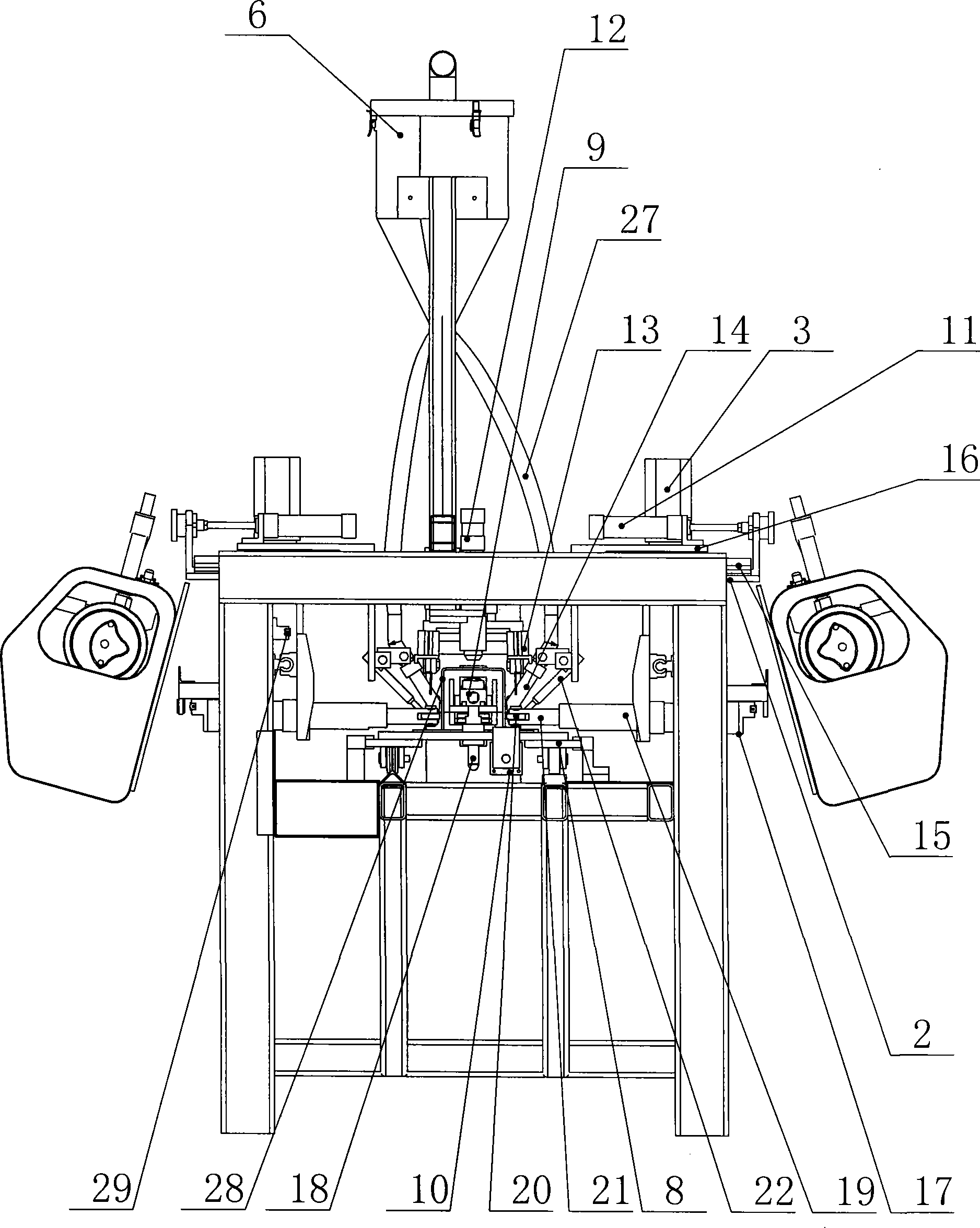

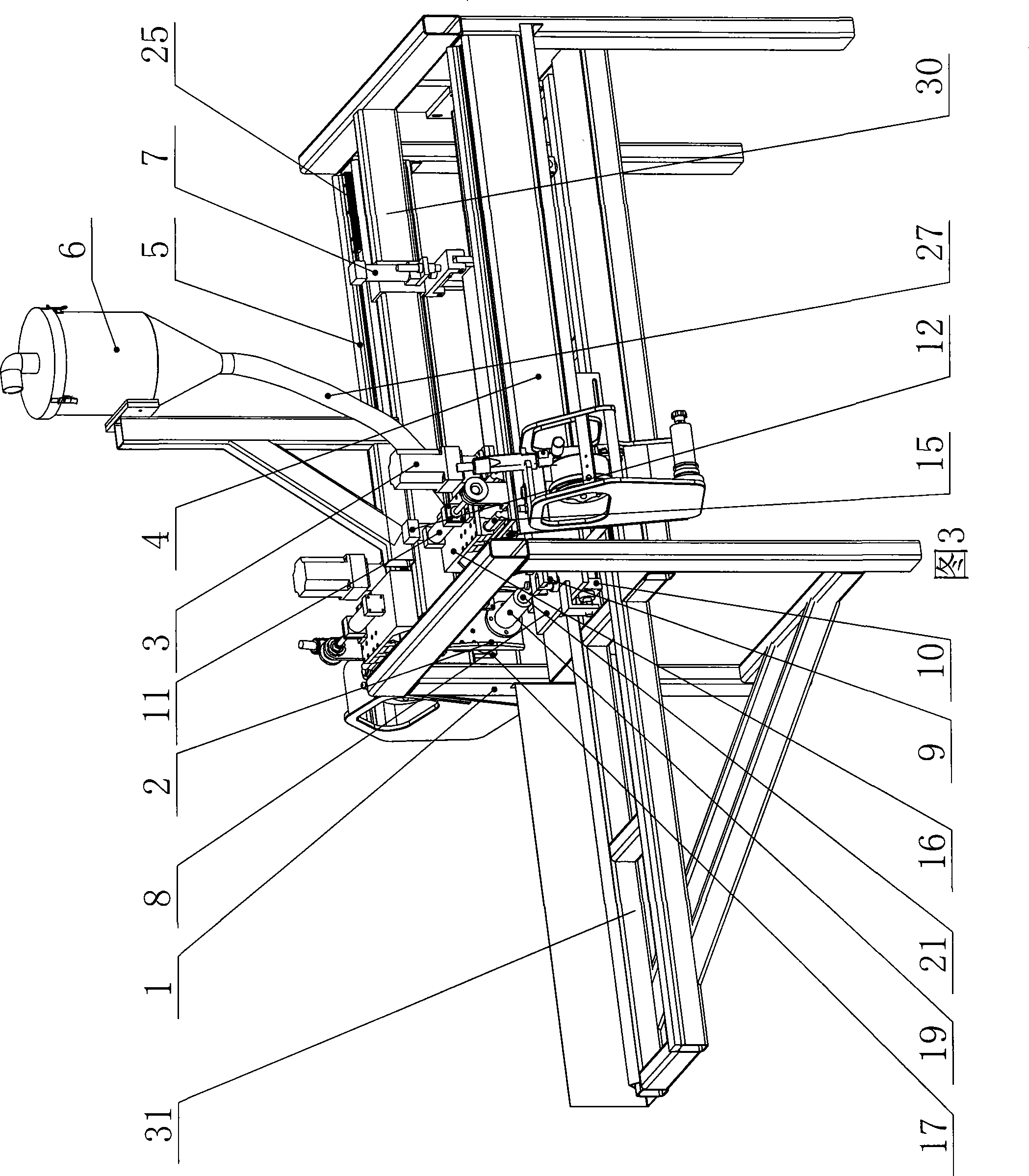

[0009] Figure 1, figure 2 As shown in Fig. 3, the automatic welding machine for longitudinal seam of legs according to the present invention includes a frame 1, a top beam 30 is arranged on the top of the frame 1, a crossbeam 4 is arranged on one side of the frame 1, and an upper guide rail 5 is arranged on the crossbeam 4 , the welding mechanism is installed on the upper guide rail 5, the front positioning and pressing device 12 is installed on the top beam 30, the welding platform 8 is installed on the frame 1, the inner lining plate device 9 is installed on the welding platform 8, and the front positioning and pressing device 12 is located in the inner lining above the plate assembly 9. The welding mechanism can be a welding torch, and the welding torch can move back and forth along the upper guide rail 5 to adjust the position of the welding torch 22 . During use, the welding workpiece 28 is placed on the welding platform 8, the inner liner device 9 is positioned in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com