Method for manufacturing multiple-layer composite floor

A multi-layer composite, manufacturing method technology, applied in the direction of manufacturing tools, adhesive types, aldehyde/ketone condensation polymer adhesives, etc., can solve the problems of no three-dimensional effect, waste of raw materials, inability to combine graphics, etc. The effect of strong sex, decorative antique and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

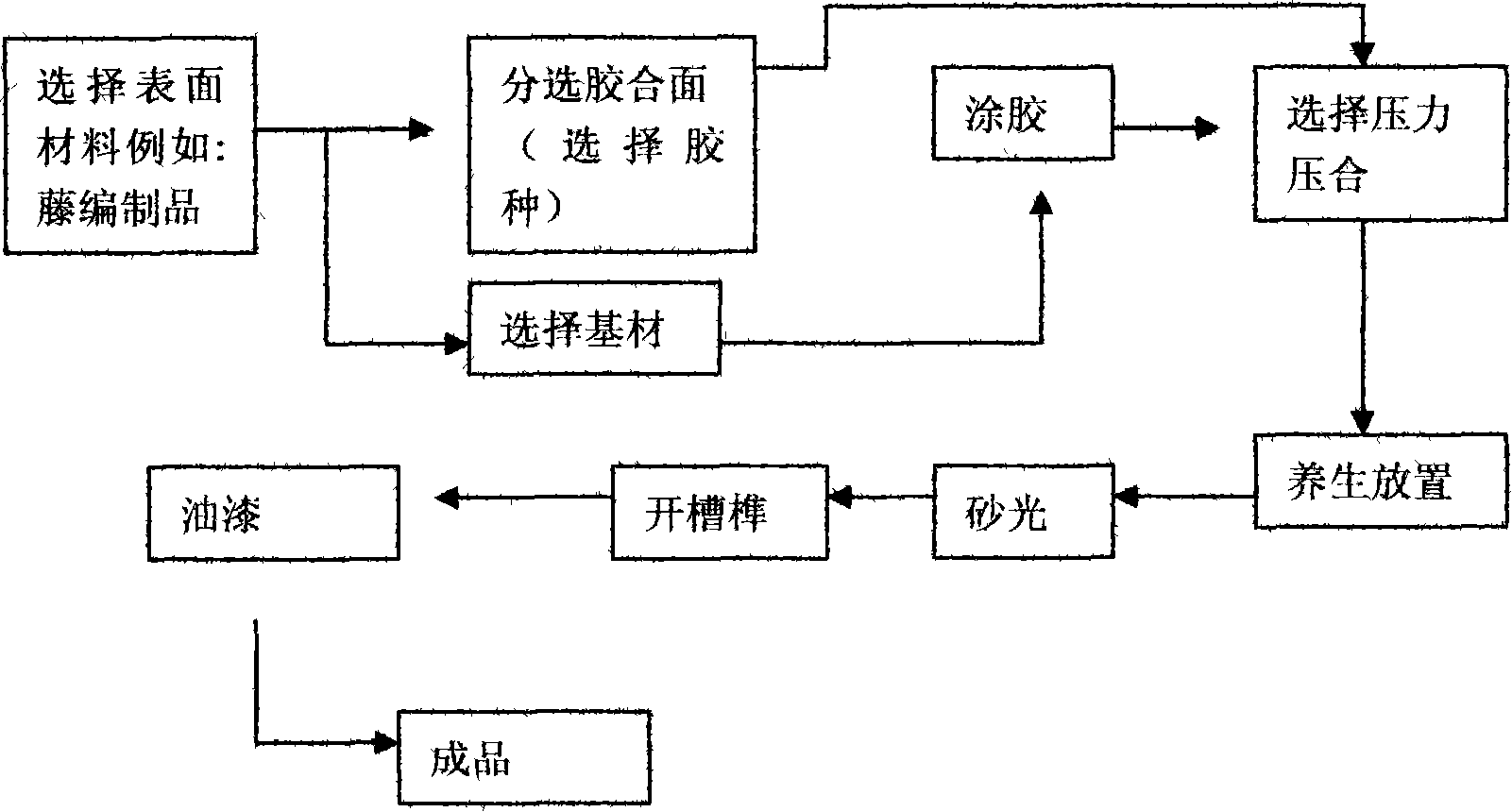

[0017] The manufacturing method of the multi-layer composite floor of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings. See figure 1 , the manufacture method concrete steps of multilayer compound flooring are as follows:

[0018] (1) Choose surface materials such as rattan or bamboo products, textiles, plastic products, animal skins, and animal hair to make veneer layers; choose wooden substrate layers;

[0019] (2), glue coating: coating amount ≤ 80g / m 2 ;

[0020] (3), Pressing: select the pressure ≤ 13kg / cm 2 Lamination;

[0021] (4) Placement for health preservation: room temperature for 48 hours, pressure 13KG / CM 2 ;

[0022] (5), surface sanding: use 60 # 80 # 100 # 120 # 150 # Lightly polish the surface with sandpaper to meet the standard of oiling or painting;

[0023] (6) Slotted tenon: The matching clearance of the slotted tenon is 0.2mm-0.5mm, and the splicing height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com