Instant heating/cooling device for injection mold and mold temperature control method thereof

A technology of instant heating and injection mold, applied in the control field of controlling the temperature of the mold, can solve the problems of poor mold temperature uniformity, larger temperature control machine, affecting production efficiency, etc., to improve the yield rate, simplify the template, improve the The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

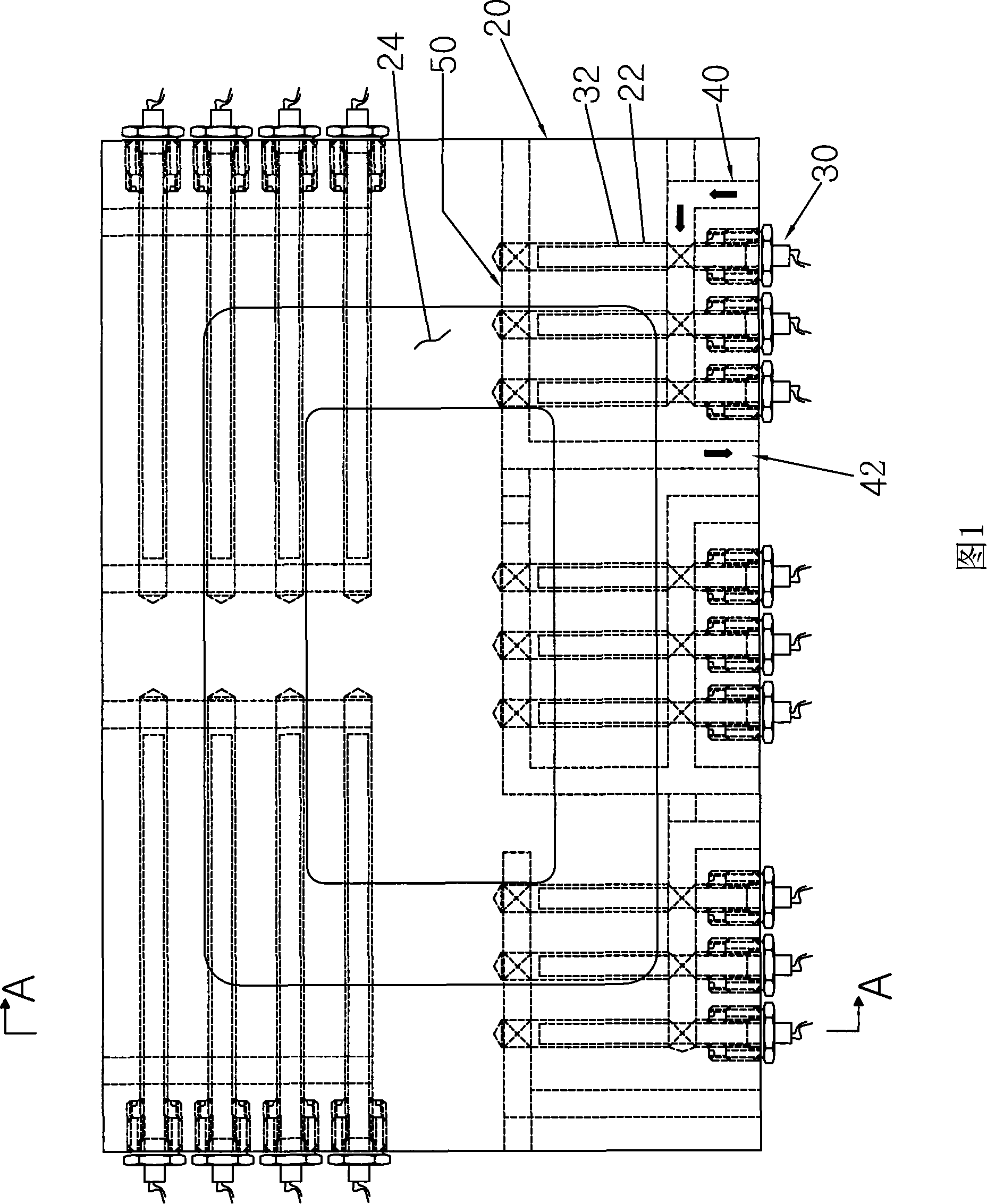

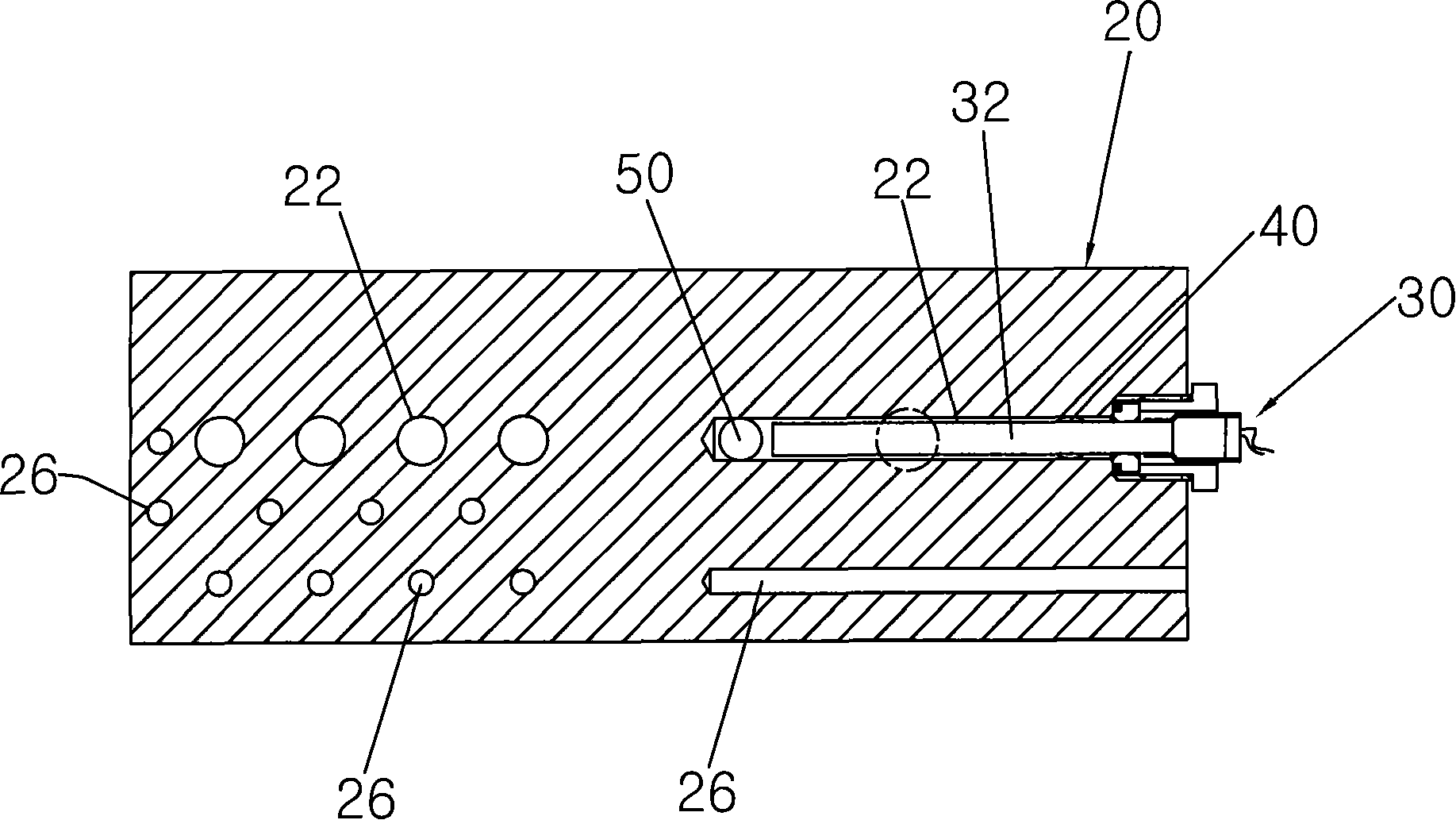

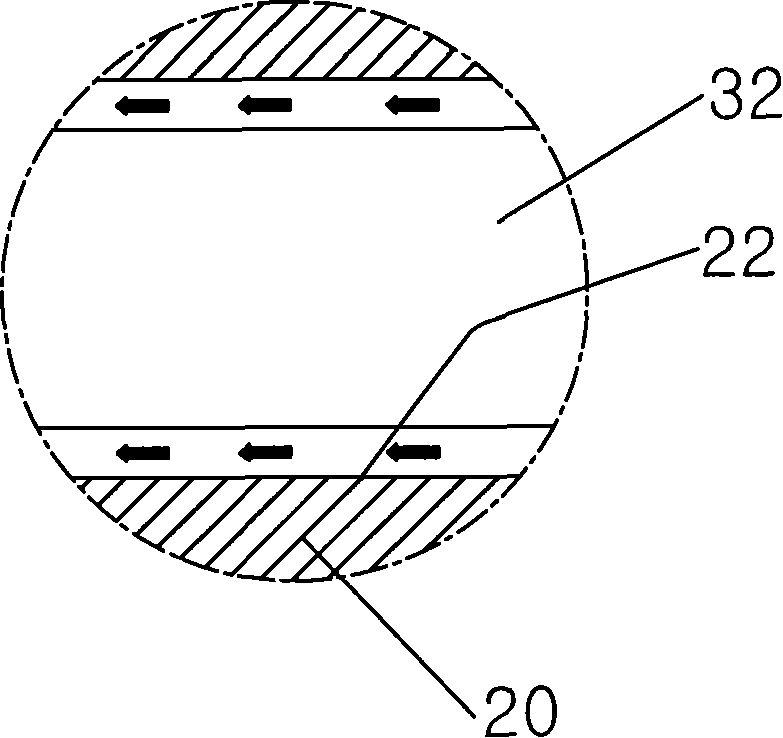

[0036] Embodiment one: see Fig. 1 to Figure 5 As shown, an instantaneous heating / cooling device for an injection mold includes a template 20, the template 20 is provided with a cavity 24, and the template 20 is provided with 5 circulating water circuits 50, which are respectively connected to the cooling water circuit 8 The inlet 40, the channels arranged around the cavity 24 and the outlet 42 connected to the cooling water circuit 8 are composed of 3 (or 4) channels connected to the circulating water circuit 50 corresponding to each channel of the circulating water circuit 50. In the joint hole 22 between the inlet 40 and the outlet 42, a heating rod 30 is inserted in each joint hole 22, and there is a gap between the heating part 32 at the inner end of the heating rod 30 and the wall of the joint hole for cooling water or the heated part 32 The saturated water vapor transformed by heating passes through, and the outer end is connected to the power supply through the heating...

Embodiment 2

[0043] Embodiment two: see Image 6 , 7 As shown, an instantaneous heating / cooling device for an injection mold, in this embodiment, its structure is similar to Embodiment 1, the difference is that: the outer edge of the heating rod 30 is spirally wound with a heat transfer plate along the length direction 60. The heat transfer plate 60 is in close contact with the inner wall of the coupling hole 22 for heat transfer between the heating part 32 of the heating rod 30 and the inner wall. The heat transfer plate 60 has a certain thickness and width, and is made of a material with a high heat transfer rate. Made, so that the heat generated by the heating part can be more effectively transferred to the inner wall of the bonding hole, and the heating template 20 can be heated more quickly.

Embodiment 3

[0044] Embodiment three: see Figure 8 , 9 As shown, an instantaneous heating / cooling device for an injection mold, in this embodiment, its structure is similar to that of Embodiment 1, the difference is that: the outer edge of the heating rod 30 is evenly distributed with a plurality of 32 a heat transfer plate 60 extending in the length direction, the heat transfer plate 60 is in close contact with the inner wall of the coupling hole 22 for heat transfer between the heating rod 30 and the inner wall, the heat transfer plate 60 has a certain thickness and width, and adopts heat transfer Made of high-efficiency materials, the distance between adjacent plates can be adjusted according to the needs of heat conduction, and the number of heat transfer plates can be increased or decreased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com