Ultraviolet flame sensor and manufacturing method thereof

A flame sensor and ultraviolet technology, which is applied in the field of flame detectors, can solve the problems that the rigidity and impact resistance of the detector need to be improved, it is difficult to ensure the distance and parallelism between the cathode and the anode, and the reliability and consistency of the sensor are not good. Guaranteed electrode distance and sensitivity, small and beautiful structure, little effect on working time and environmental interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

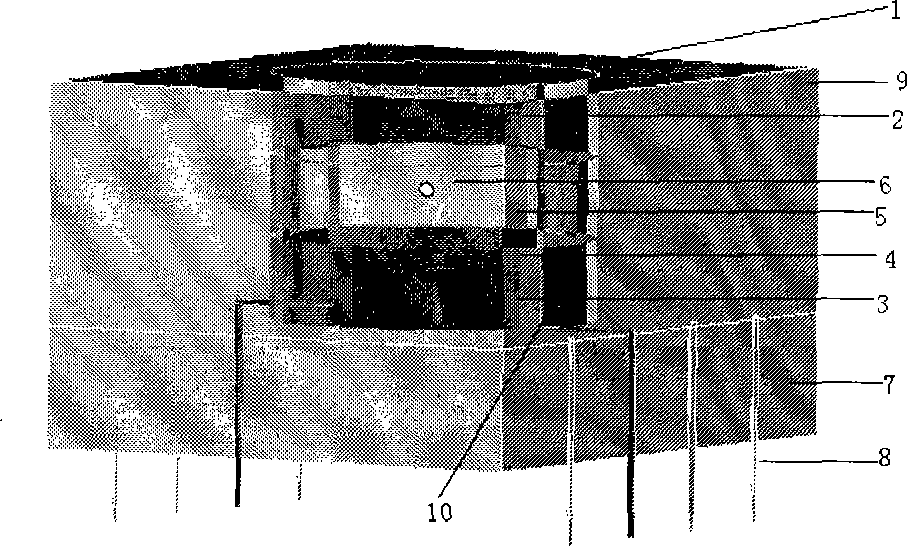

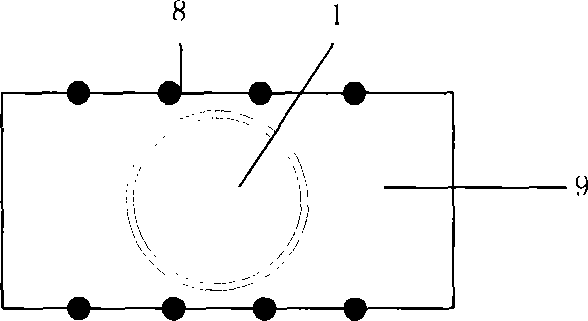

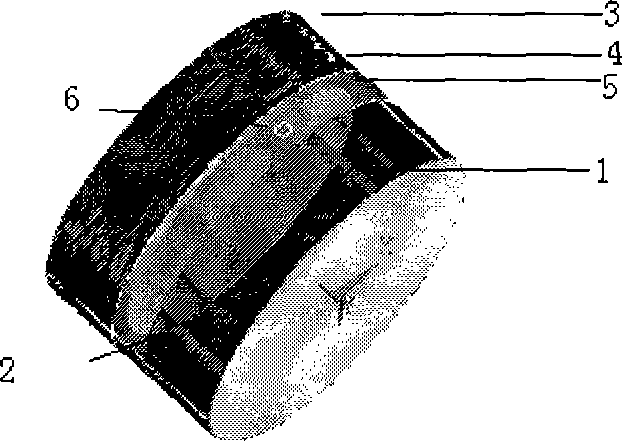

[0036] The ultraviolet flame sensor of the technical solution will be further described below in conjunction with the accompanying drawings.

[0037] refer to figure 1 and figure 2 , The invention is a novel ultraviolet flame sensor with compact structure, good impact resistance and high rigidity. The electrode anode 2 is plated on the lower layer of the transparent purple glass sheet 1, the photocathode 4 is plated on the upper surface of the cathode substrate glass sheet 3, and the upper and lower glass sheets and the glass ring 5 form a glass cavity. The glass cavity is bonded on the plastic base 7 , and the electrode leads are connected to the aeration circuit wires 10 on the plastic base 7 and connected to each pin 8 . The plastic-encapsulated base 7, the glass cavity and the plastic shell 9 are hermetically bonded to form an integrated compact detector. Therefore, the structure is relatively solid, the rigidity and impact resistance of the detector are improved, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com