Device and method for picking up semiconductor chip

A pick-up device, semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as difficulty in reliably preventing damage, slow pick-up speed, and reduced productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

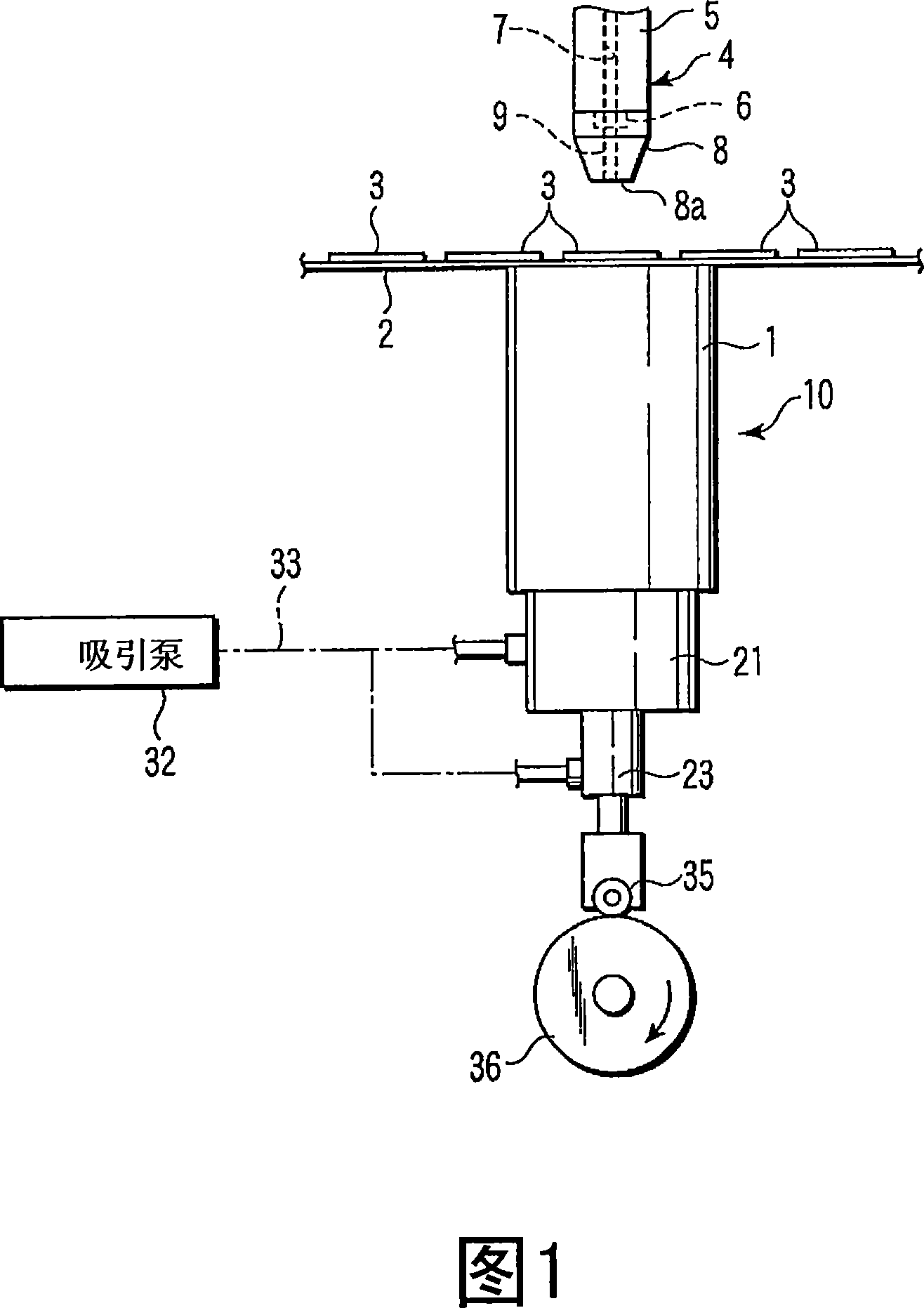

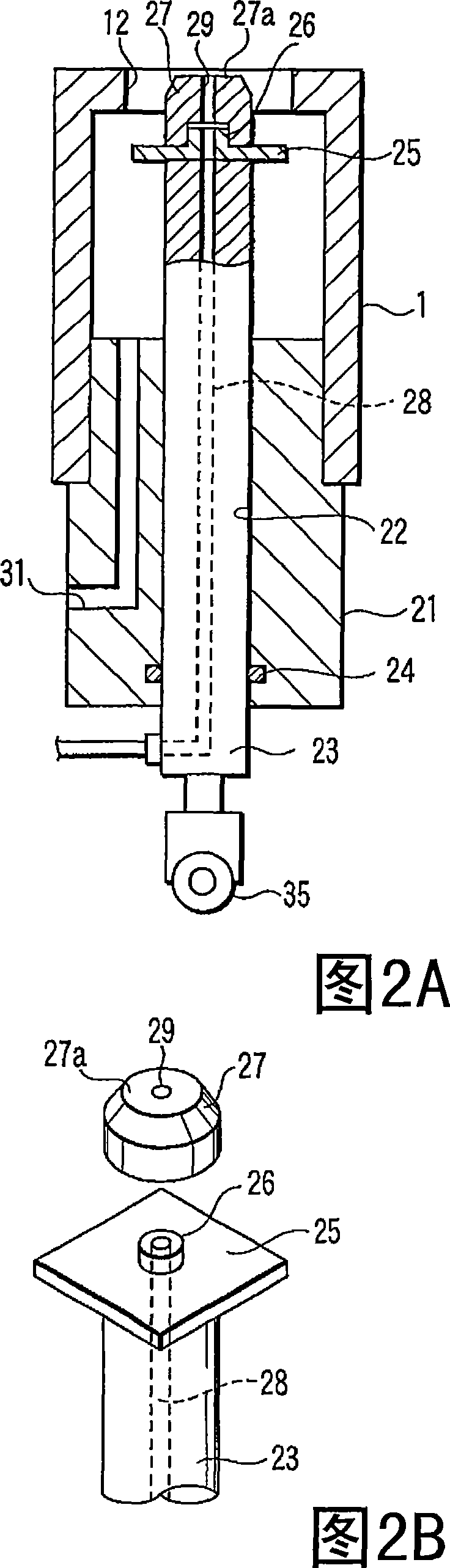

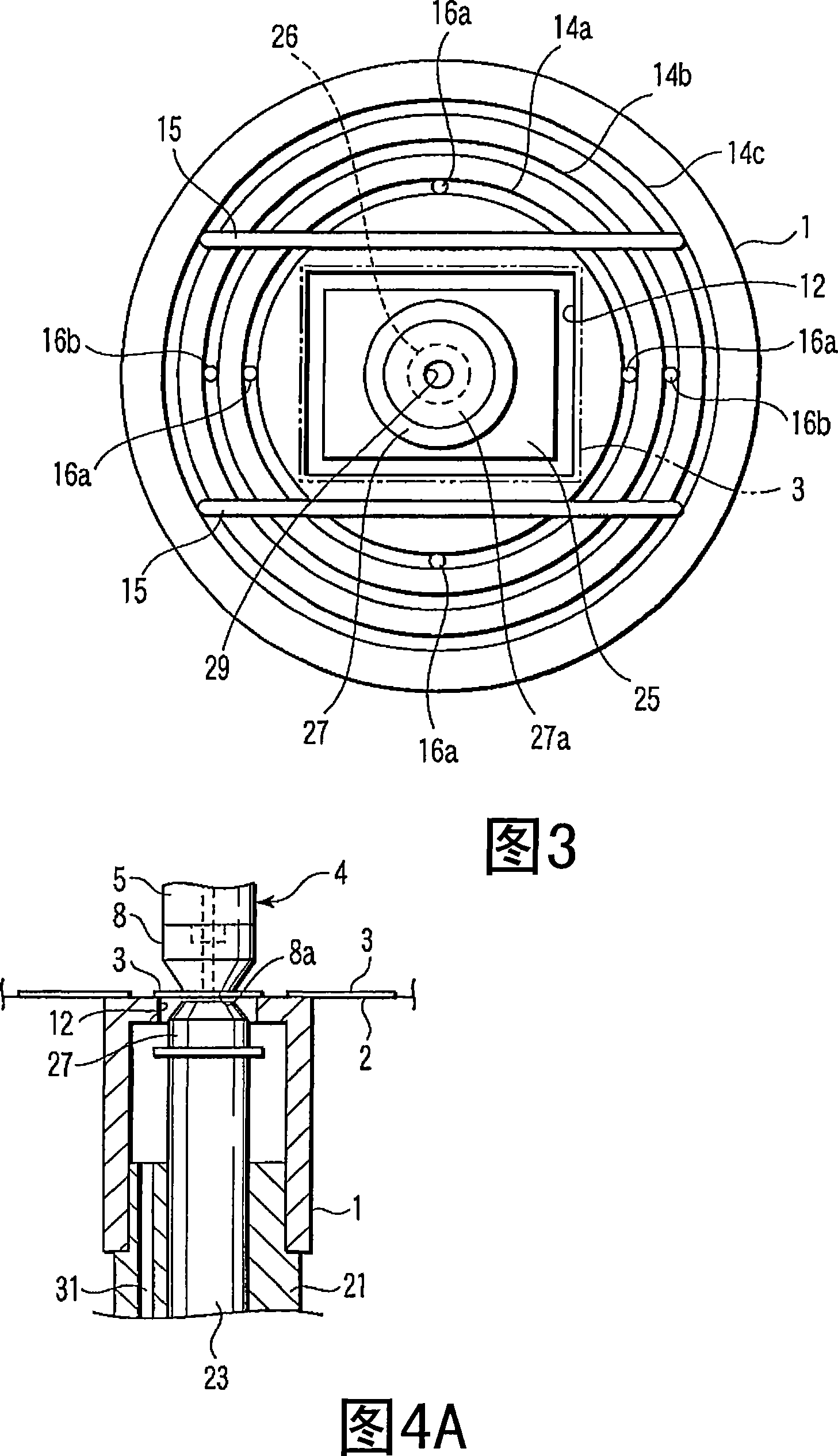

[0031] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings.

[0032] 1 to 5 show a first embodiment of the present invention. The pickup device shown in FIG. 1 has a support unit 10 . This support unit 10 is provided opposite to the lower surface side of the adhesive sheet 2 tensioned on the unillustrated wafer ring, and is supported along the Z direction by an unillustrated Z driving source as will be described later. The supporting unit 10 is driven between a position where the upper surface of the body 1 is in contact with the adhesive sheet 2 and a position where it is separated from the adhesive sheet 2 .

[0033] On the upper surface of the above-mentioned adhesive sheet 2, a plurality of semiconductor chips 3 divided into small quadrangular blocks are pasted. The wafer ring is driven in the horizontal direction by X and Y drive sources (not shown).

[0034] Accordingly, the semiconductor chip 3 attached to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com