Smoked sheet multiple roasting method and special-purpose equipment thereof

The invention relates to a special equipment and a technology for tobacco sheets, which are applied in the field of tobacco sheet redrying methods and special equipment, and can solve the problems of limited service life of magnetrons, difficulty in achieving high-flow redrying, and manufacturing power limitations, and achieve the goal of maintaining sensory quality, Small shredding, reducing the effect of shredding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

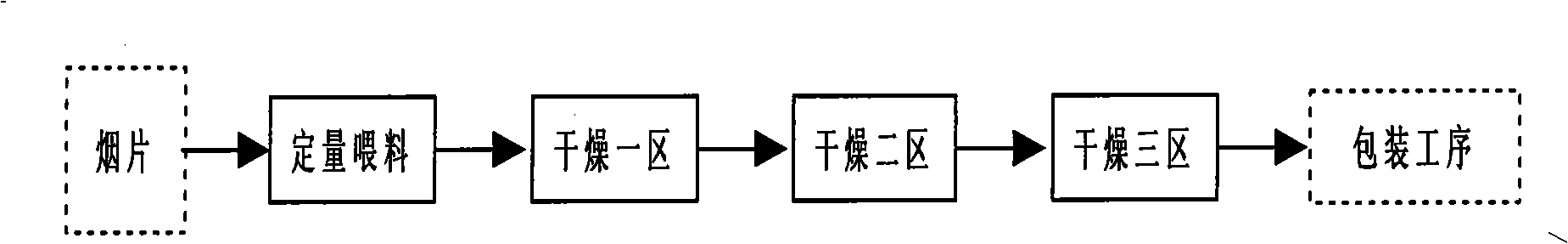

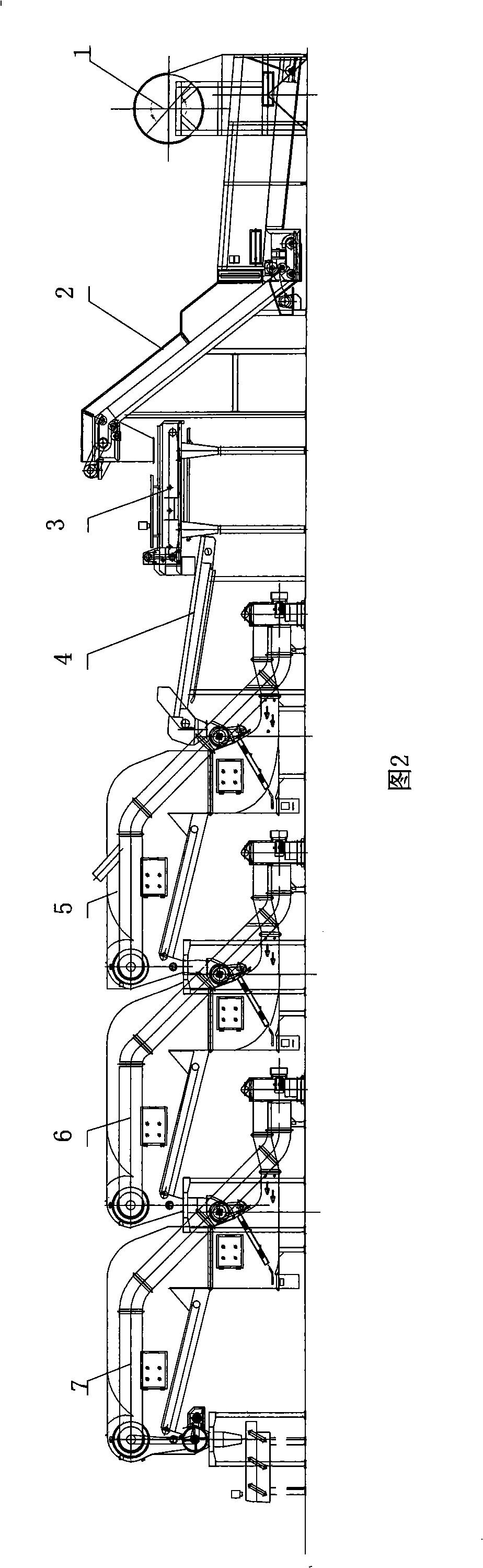

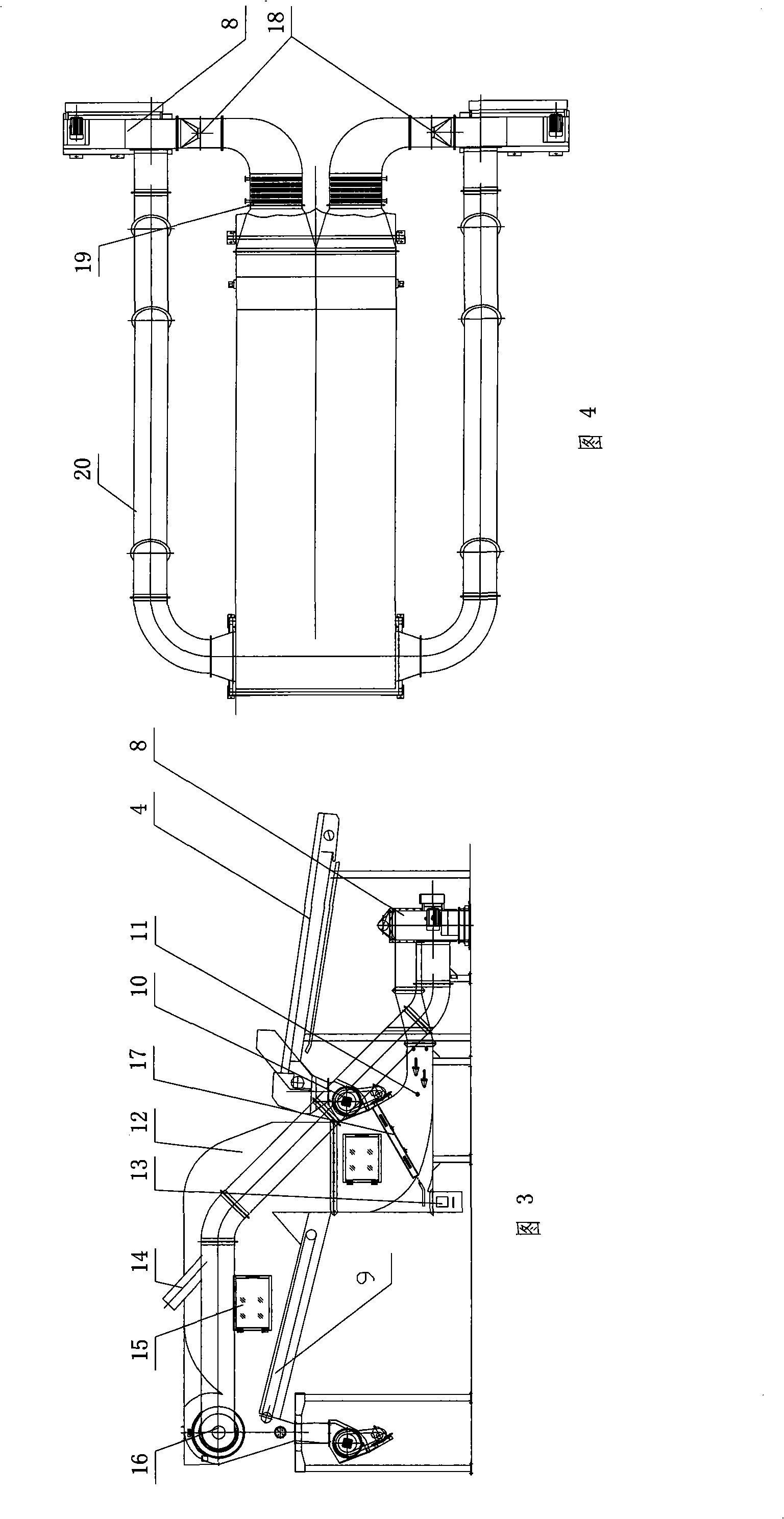

[0023] like figure 1 As shown, the tobacco sheet rebaking method of the present invention comprises the following steps: the tobacco sheet to be rebaked is fed into the storage feeder by the control of the feeder, such as a scraper feeder, and is set after the storage feeder. After being measured by the electronic scale, it is sent to the air-flow type tobacco sheet re-baking equipment through the belt conveyor at a constant flow rate, and then passes through the three serial drying areas of the air-flow drying chamber of the air-flow type tobacco sheet re-baking equipment. The hot air convection heating heats the fluidized tobacco sheets, and the three drying areas of the airflow drying chamber respectively realize the temperature rise, rapid dehydration and moisture balance of the leaves, so that the moisture in the tobacco sheets does not need to be cooled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com