Plat type heat transfer machine

A thermal transfer machine, flat-bed technology, applied in rotary printing machines, printing machines, transfer printing, etc., can solve the problems that the transfer paper cannot be uniformly thermally transferred, cannot be quickly thermally transferred, and has poor results. Achieve uniform heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

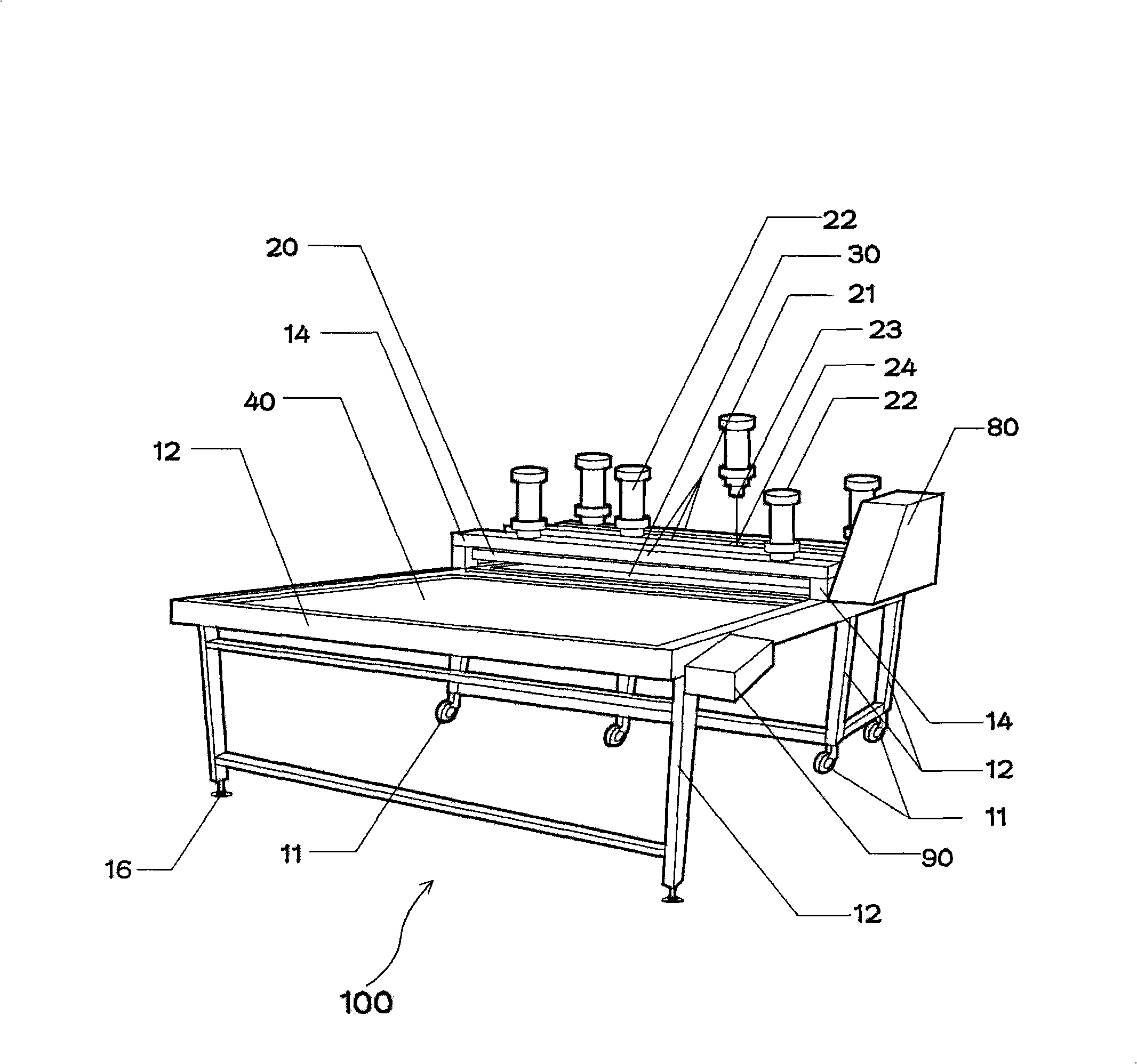

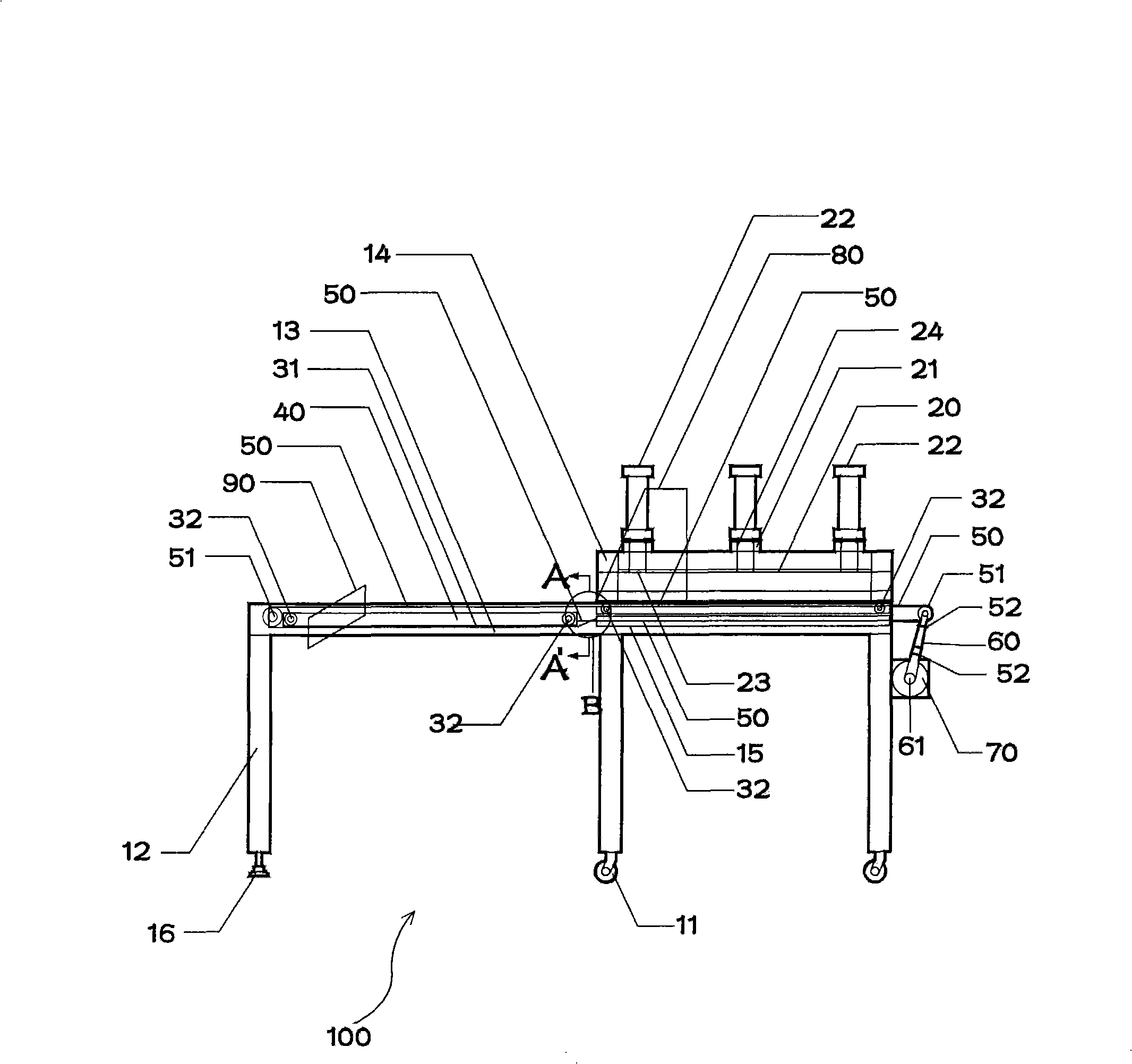

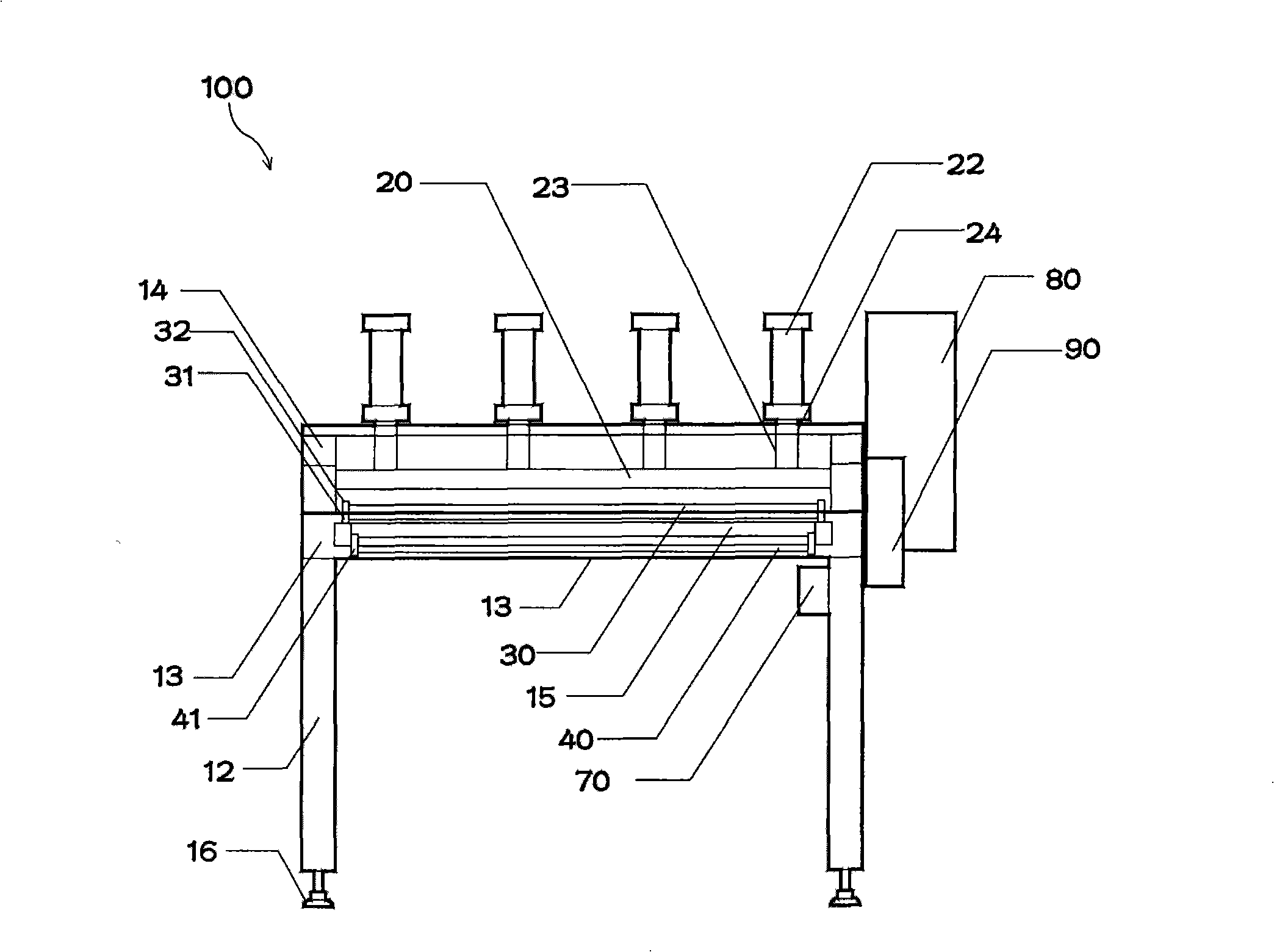

[0032] Such as Figure 1-6 As shown, the flatbed thermal transfer machine 100 consists of a body 10 and a base 15, a bracket 21, a cylinder 22, an electric heating plate 20, the first and second transfer parts 30, 40, the first and second connecting members 50, 60, and the motor 70 , The first and second control components 80,90 are composed.

[0033] The above-mentioned body 10 is composed of a frame 13 and a supporting frame 14, the upper face of the frame 13 forms a base 15, and the supporting frame is located above the rear side of the frame.

[0034] Several supports 12 are arranged below the above-mentioned frame, and the support at the front part of the above-mentioned frame 13 forms a fixed ring 16 at the bottom;

[0035] The electric heating plate 20 forms a plurality of brackets 21 at the lower part of the support frame 14 , and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com