Oscillatory type non-straight-long bar automatic sorting feeding machine

An automatic sorting and vibrating technology, which is applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of low accuracy of feeding position, jamming or blocking of steel bars, and high labor intensity, so as to improve stability and reliability performance, ensure stable material supply, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

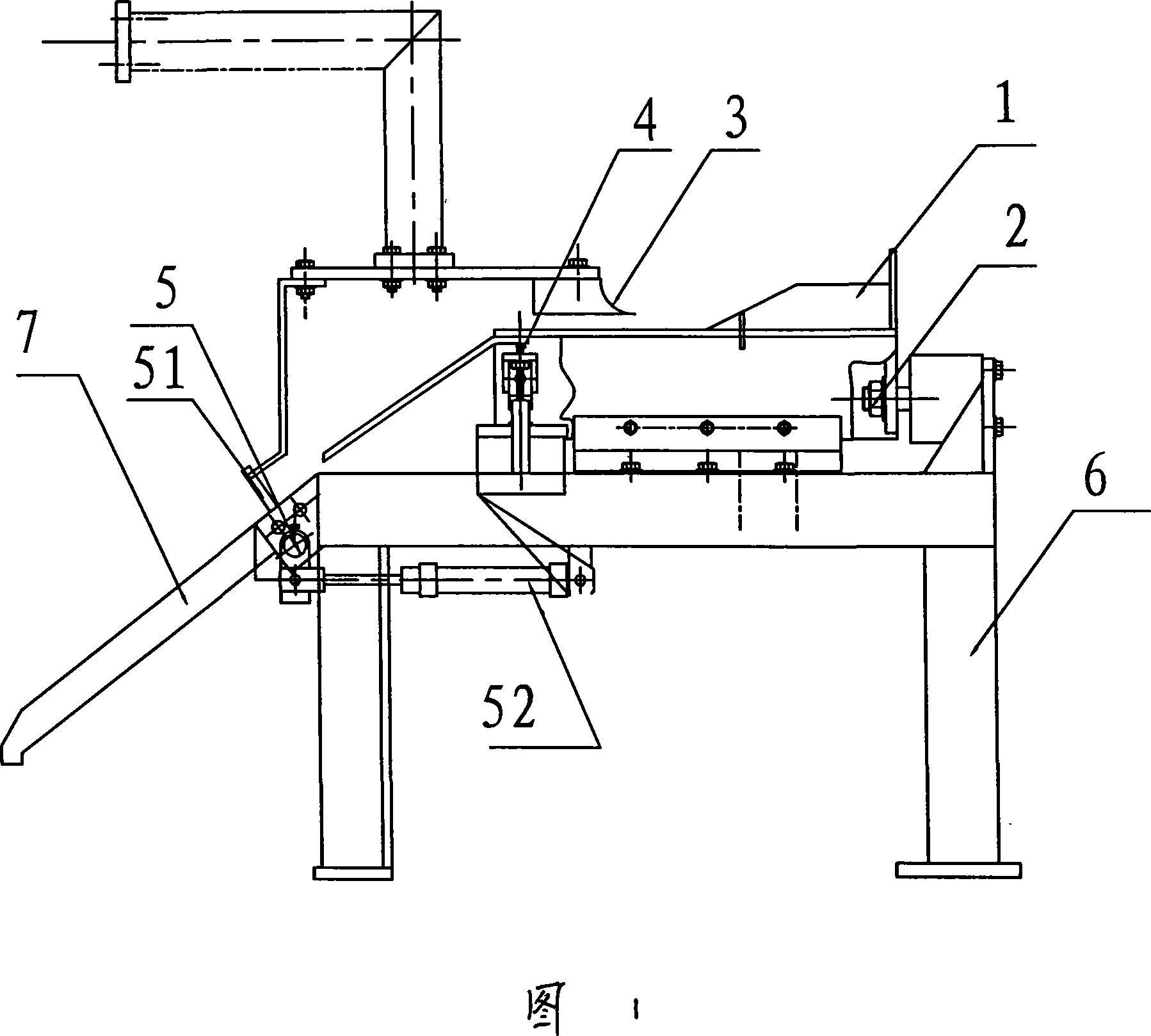

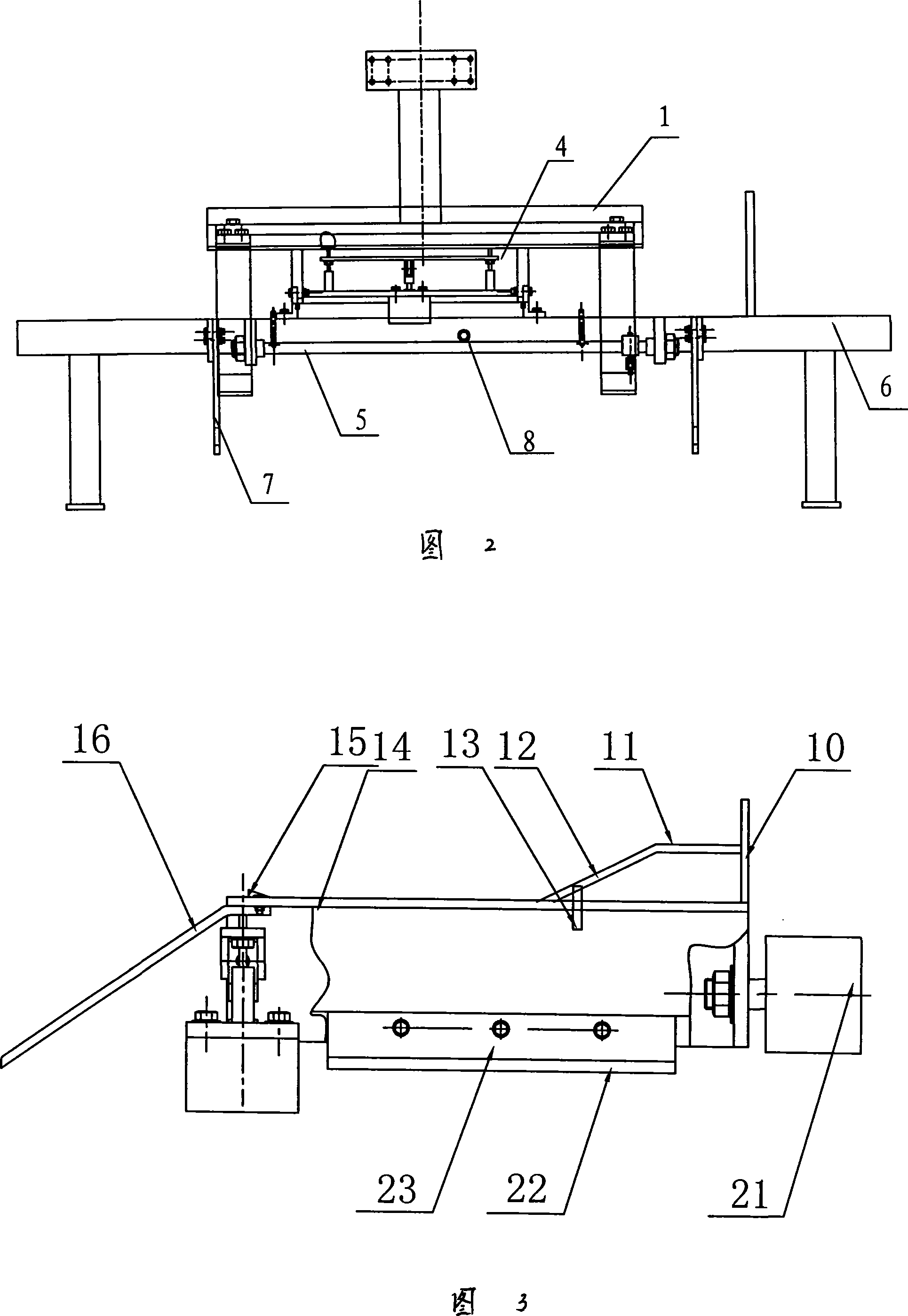

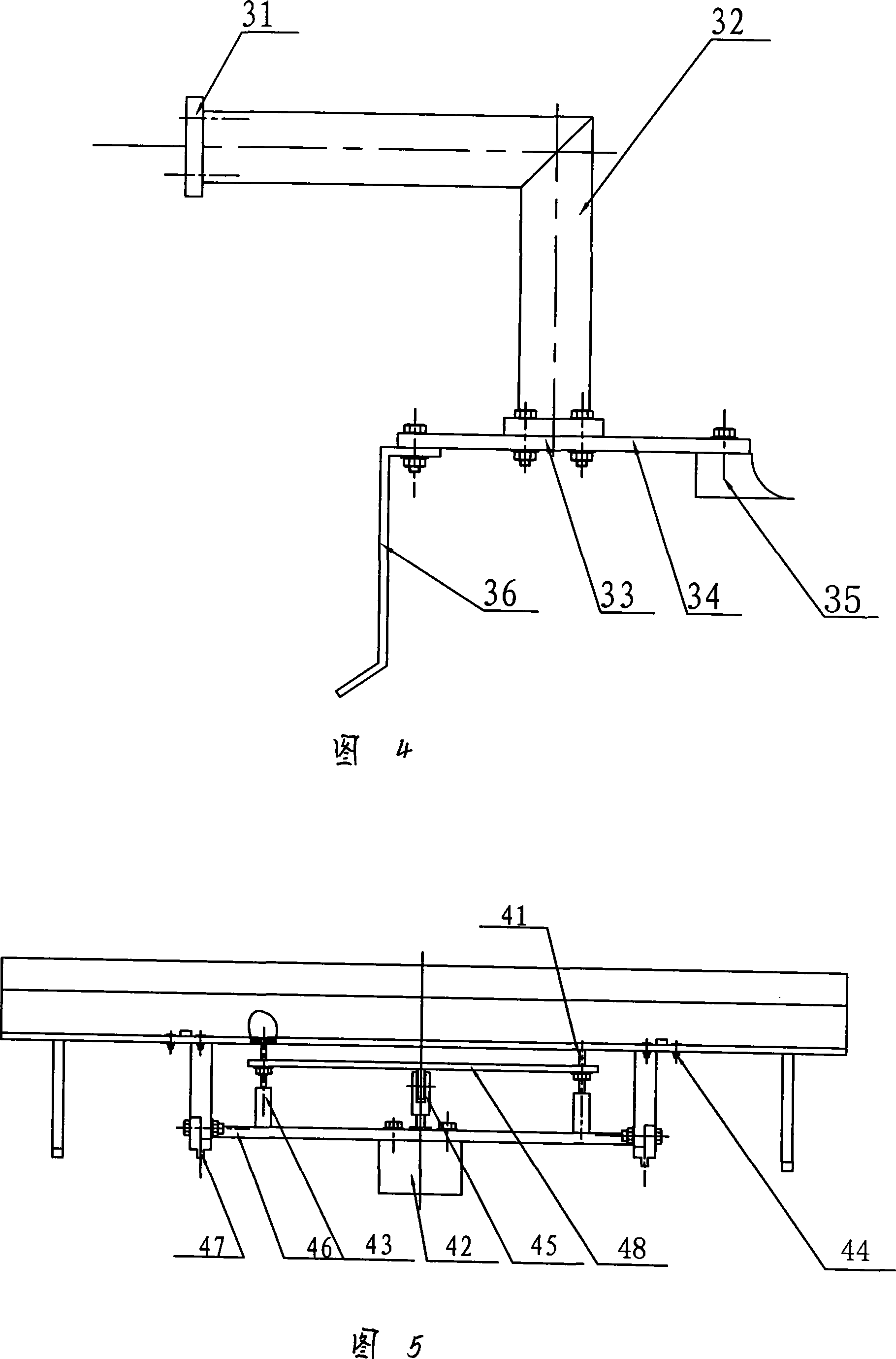

[0017] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

[0018] As shown in Figures 1 and 2, the automatic sorting and feeding machine for vibrating non-straight rib materials includes a feed bin 1 and a frame 6, and is characterized in that it also includes: the frame 6 is equipped with There is a vibrating mechanism 2, the feed bin 1 is arranged on the vibrating mechanism 2, and the feeding mechanism 7 is arranged on one end of the frame 6; Described material receiving mechanism 7 is provided with material receiving position adjustment mechanism 5, is provided with photoelectric switch 8 on the frame 6 of the bottom of material receiving position adjustment mechanism 5; Described material receiving position adjustment mechanism 5 is for receiving material The top of the mechanism 7 is provided with a stop rod 51 and a cylinder 52 connected to the stop rod. The lower end of the stop rod 51 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com