Device for etching TFT LCD glass substrate and etching method thereof

A glass substrate and etching device technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of complicated etching process and increased etching time, and achieve the effect of shortening etching time and simplifying etching process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

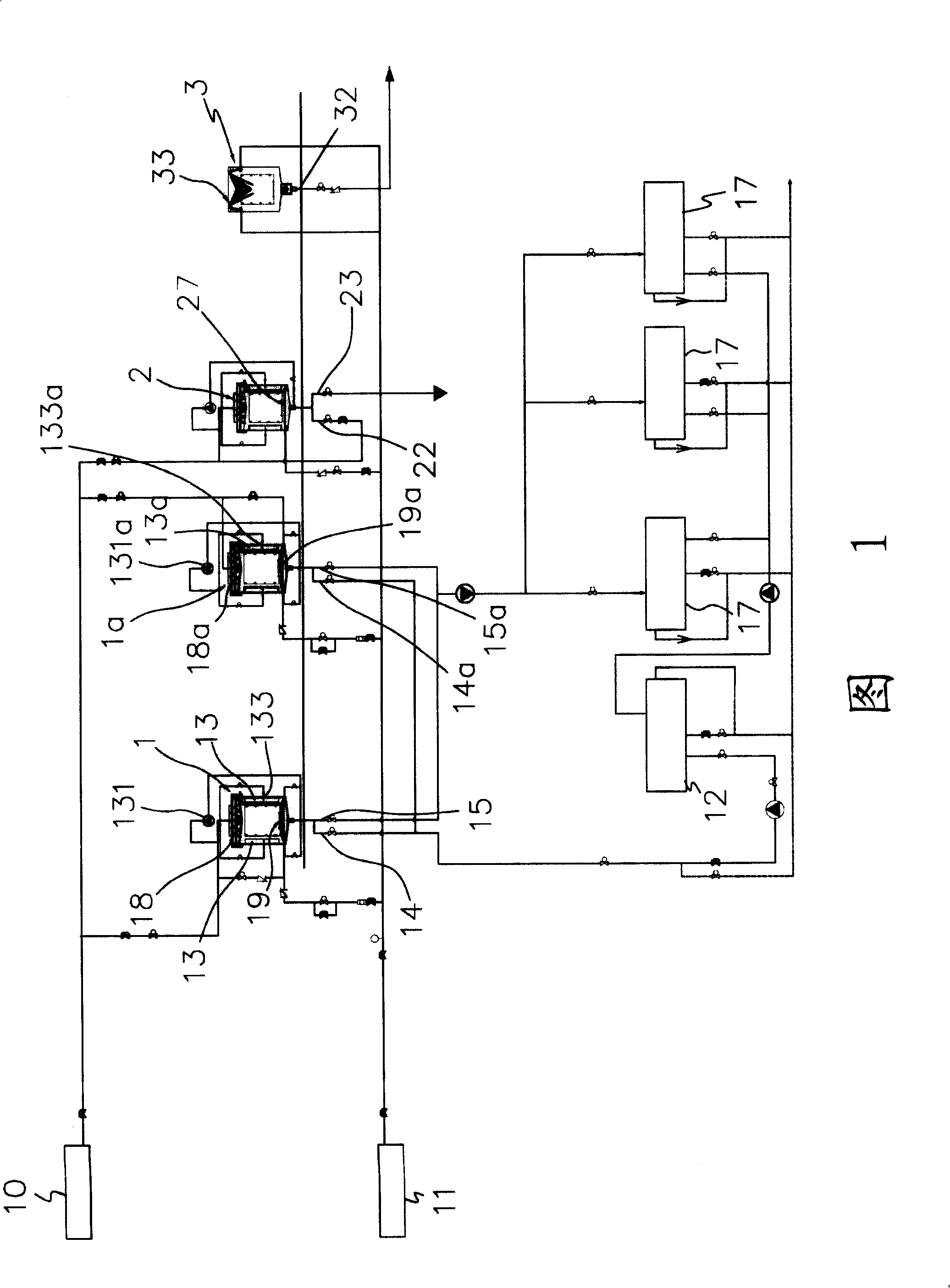

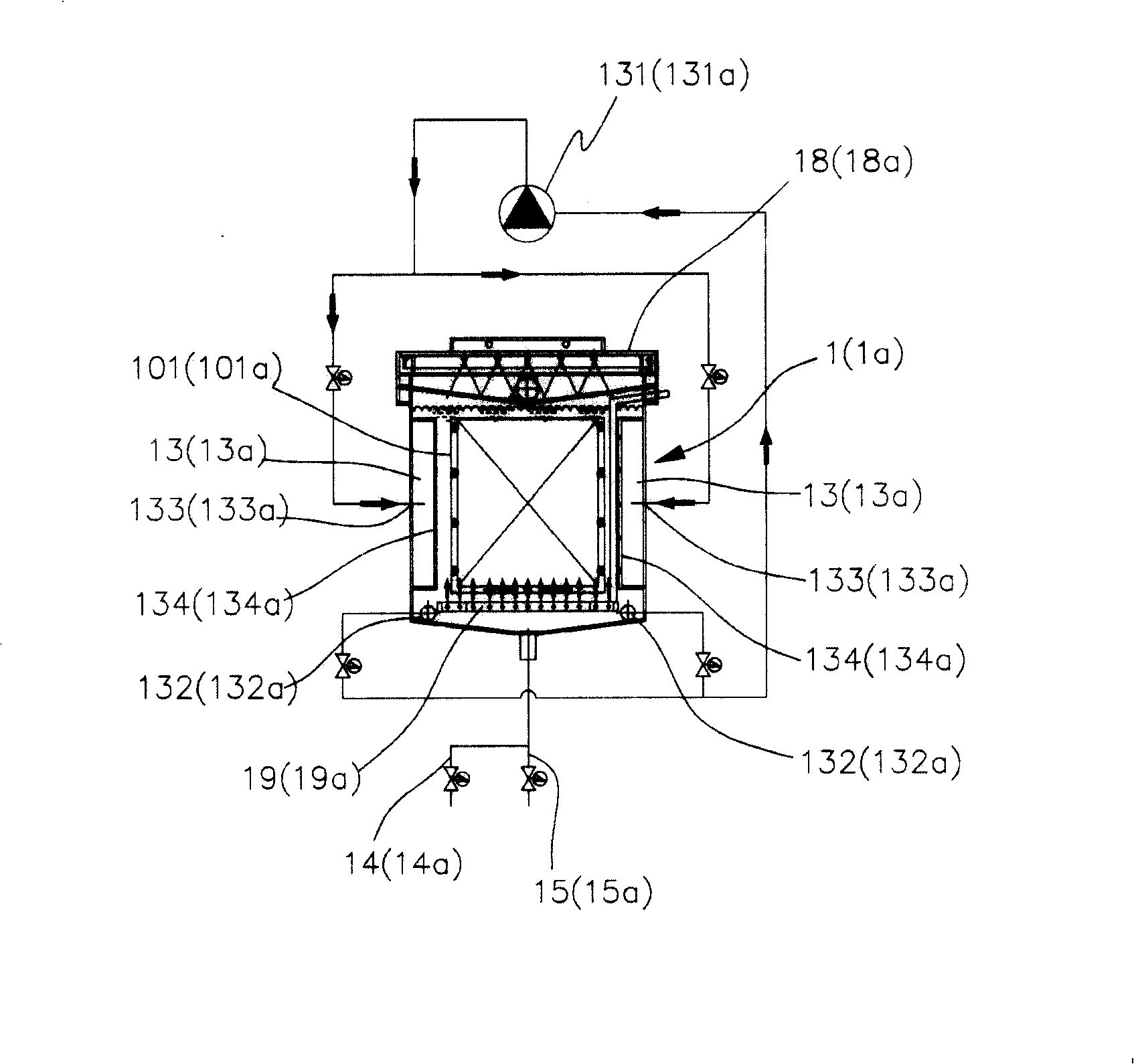

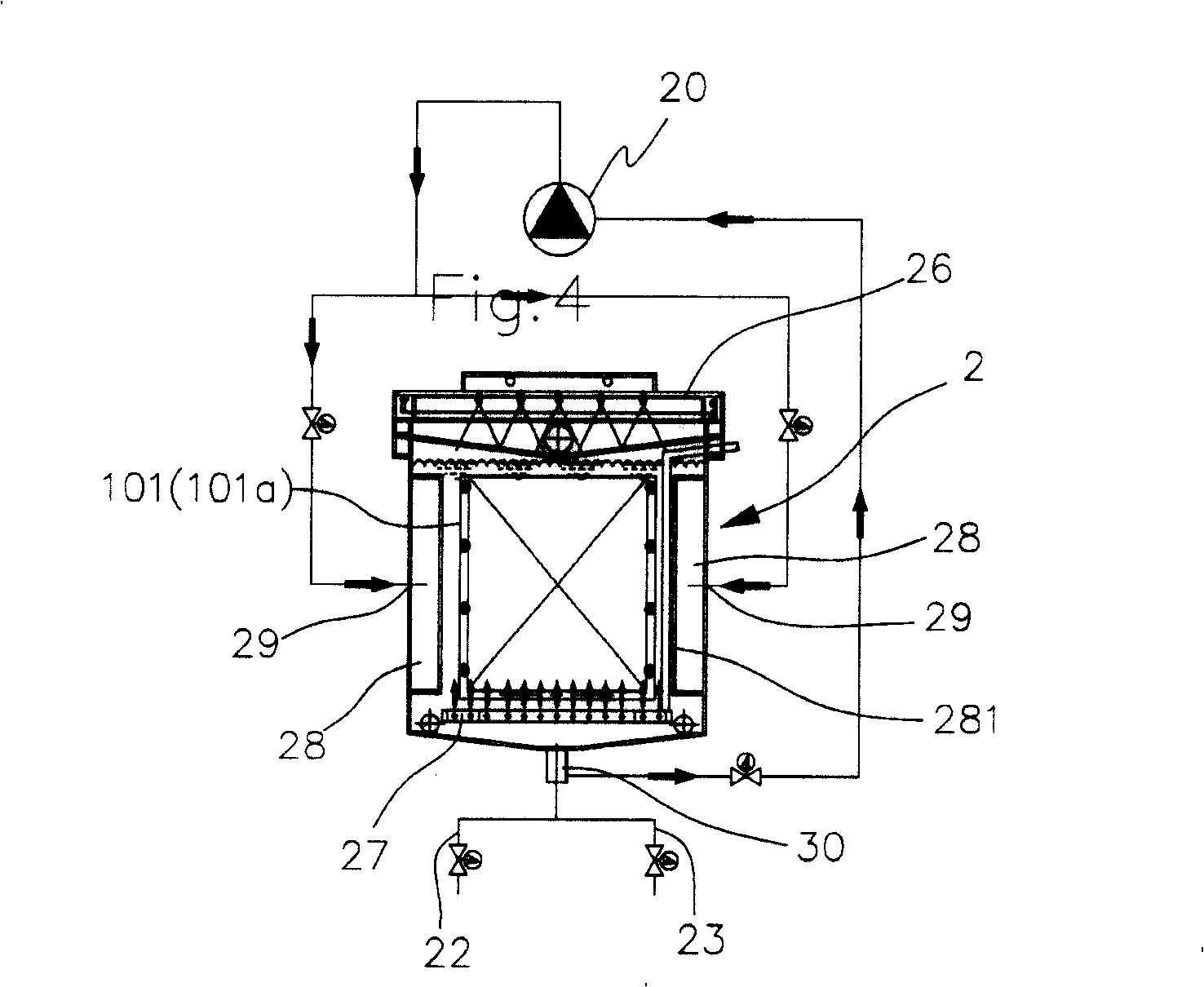

[0040] As shown in Figures 1-4: the present invention is an etching device for a TFT LCD glass substrate, which consists of at least two carrying boxes 101, 101a, two etching cleaning tanks 1, 1a, a cleaning tank 2, and a drying tank 3, the etching of a plurality of TFT LCD glass substrates of the two carrier boxes can be completed simultaneously in one process, so as to achieve the effects of shortening the etching time and simplifying the etching process.

[0041] The above-mentioned carrying boxes 101, 101a can carry the TFT LCD glass substrate to be etched, and each carrying box 101, 101a can be defined as at least a first carrying box 101 and a second carrying box 101a.

[0042] Each etching cleaning tank 1, 1a can be defined as at least a first etching cleaning tank 1 and a second etching cleaning tank 1a, and each etching cleaning tank 1, 1a can be used for accommodating the above-mentioned first and second carrying TFT LCD glass substrates. Carrying boxes 101, 101a, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com