Knitting plating method and knitting parts used thereof

A technology for knitting components and knitting yarns, which is applied to weft knitting, circular knitting machines for weft knitting with separate action needles, knitting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

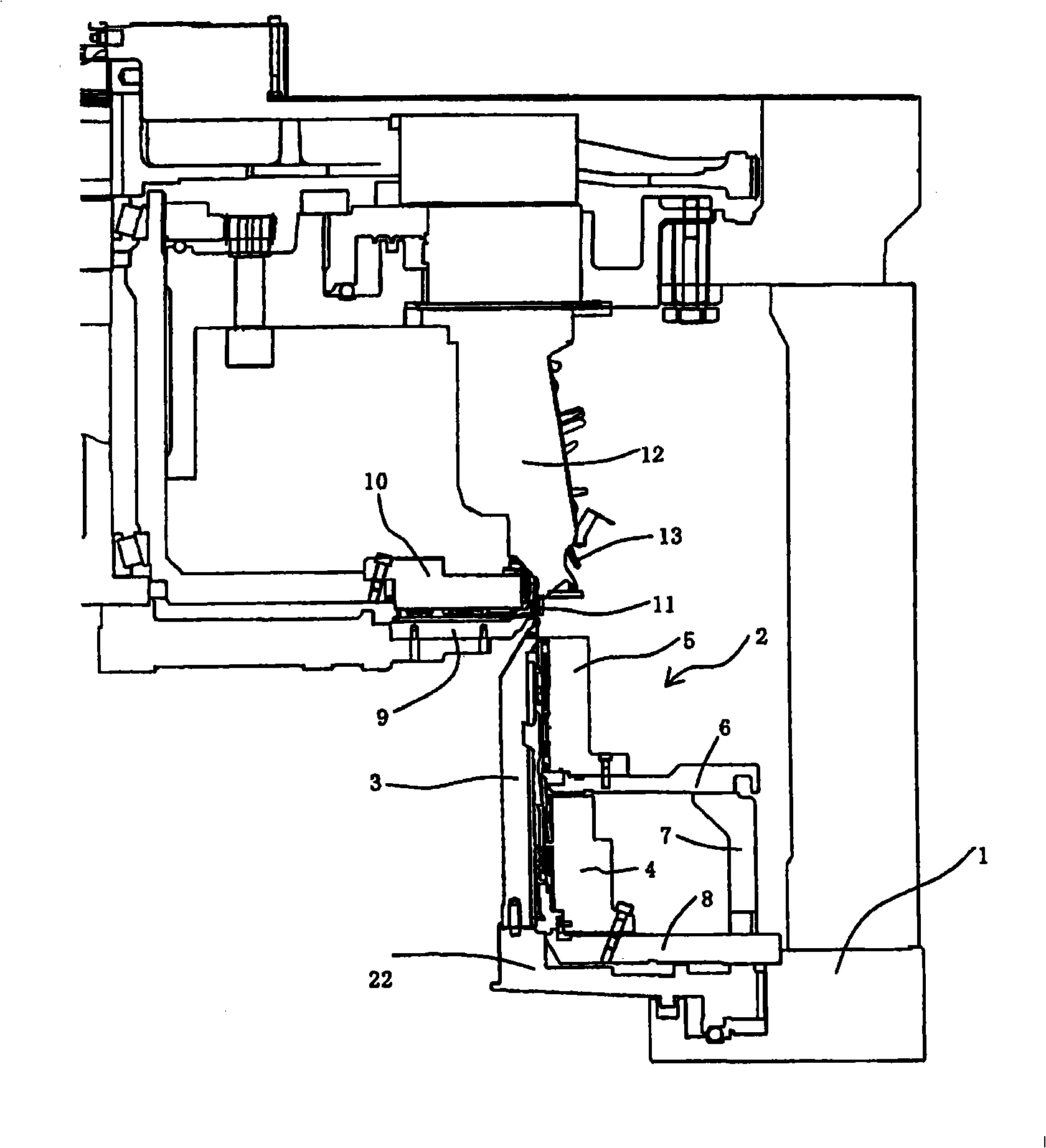

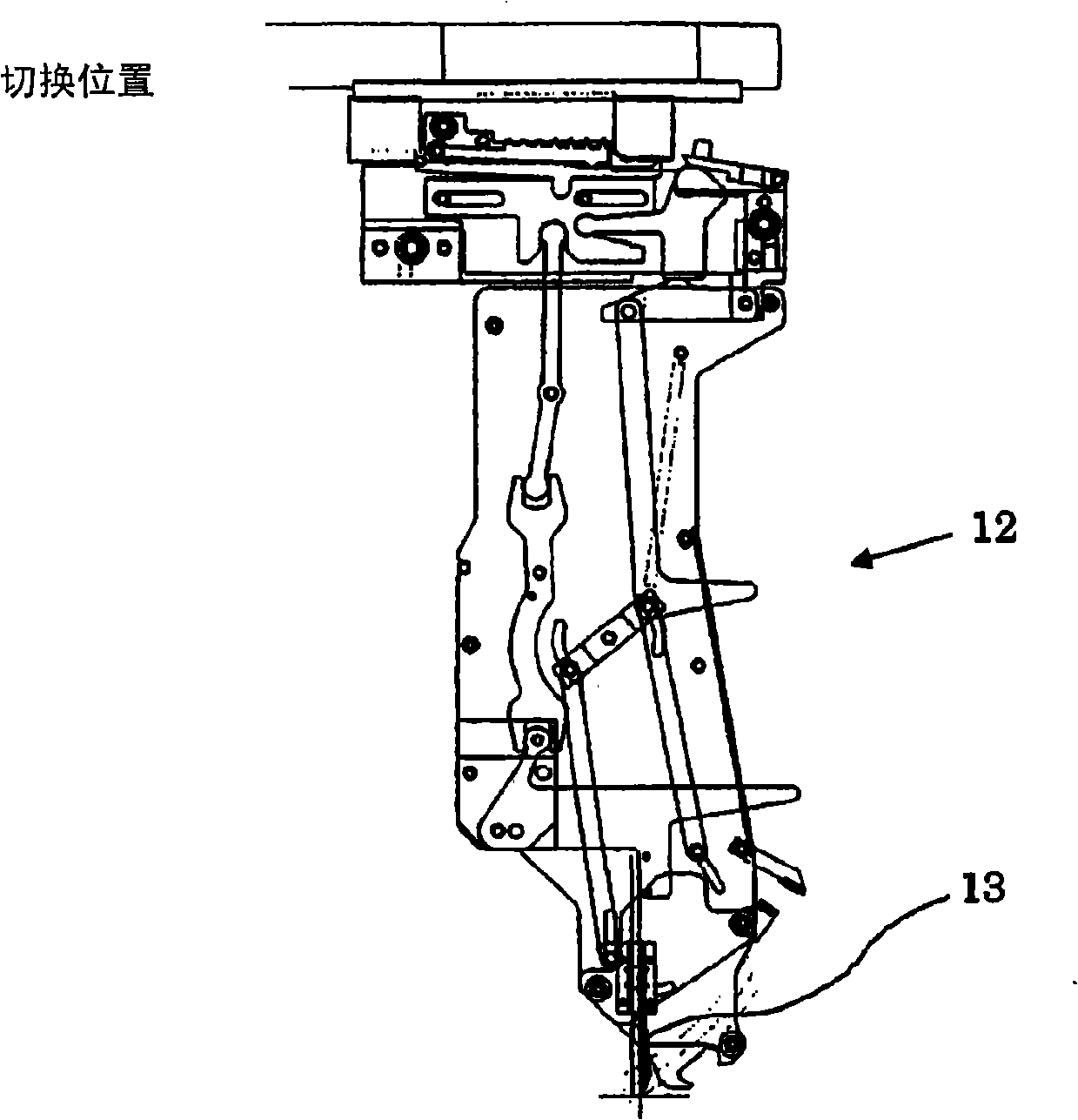

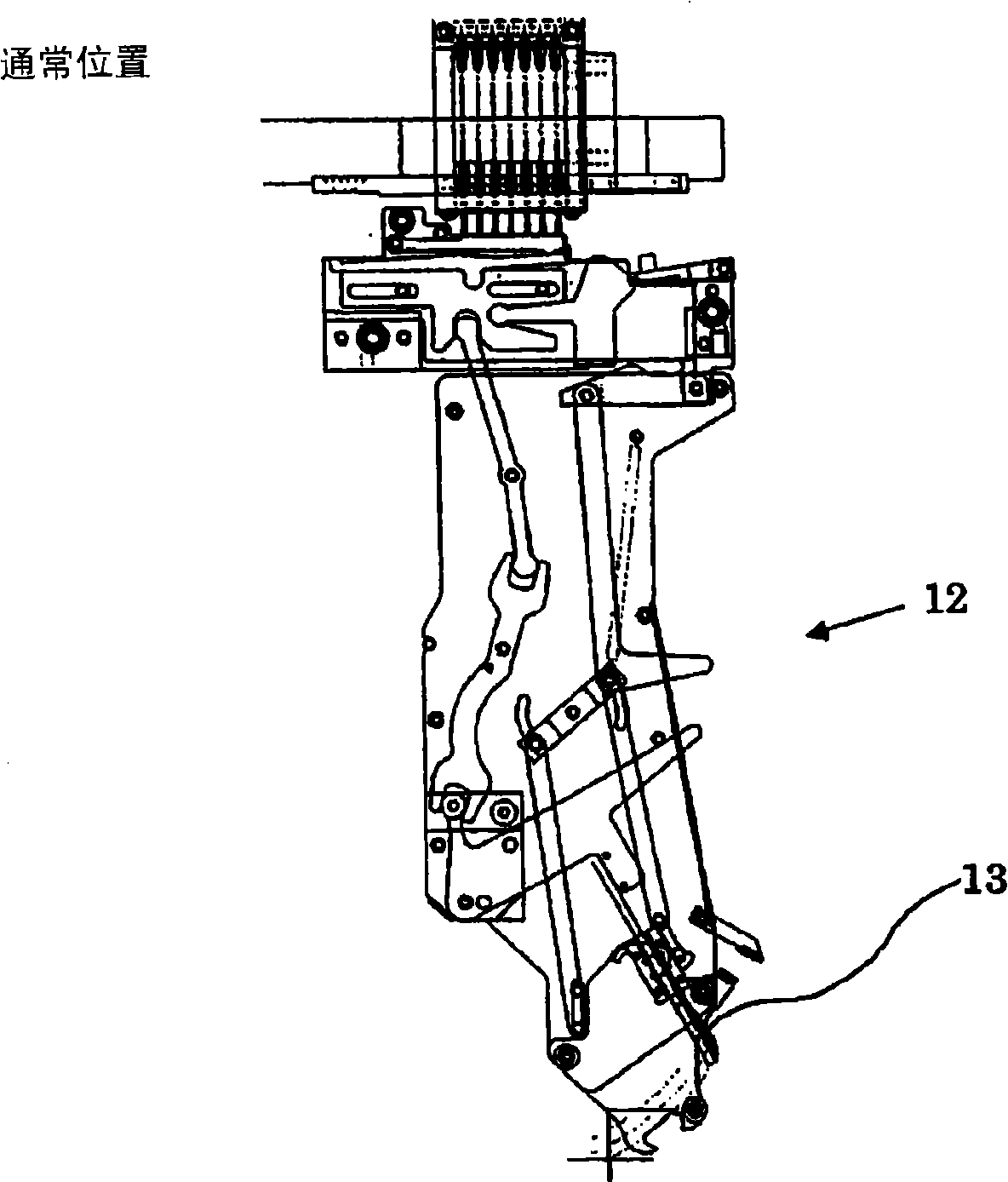

[0050] figure 1It is a sectional view showing main parts of the knitting part of the double-knit circular knitting machine. A braided portion 2 is provided above a base 1 supported by a plurality of brackets (not shown). Symbol 3 among the figure represents syringe. A cylinder needle (not shown) that is slidable in the vertical direction is housed in an upper portion of a needle groove (not shown) formed on the outer periphery of the needle cylinder 3 .

[0051] A bottom piece (not shown) for controlling the needle of the needle cylinder is housed in the lower part of the needle groove of the needle cylinder 3 . A needle selector 4 is arranged opposite to the lower part of the needle cylinder 3 to control the foot piece so as to display patterns on the fabric. A cylinder cam holder 5 for controlling the cylinder needle is arranged on the upper part of the needle selector 4, and the cylinder cam holder 5 is accommodated in the cylinder cam holder 5 to make the cylinder needl...

Embodiment 2

[0087] Figure 4 It is a cross-sectional view showing a knitting section of a single-jersey circular knitting machine, and a knitting section 2B is provided above a machine base 1B supported by a plurality of brackets (not shown). Symbol 3B in the figure represents a syringe. A cylinder needle (not shown) that is slidable in the vertical direction is housed in a needle groove (not shown) formed on the outer periphery of the needle cylinder 3B.

[0088] Needle selection is performed in the needle selector portion 4B facing the needle cylinder 3B to provide variations in the knitting structure. A cylinder cam 5B for controlling the cylinder needle is arranged on the upper part of the needle selector part 4B, and the cylinder needle is reciprocated up and down by a cam (not shown) accommodated in the cylinder cam 5B.

[0089] In addition, the cylinder cam 5B is supported by an annular intermediate ring 6B. The intermediate ring is supported by the lower ring 8B via the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com