Method for sealing packer outside pipe with cement paste to auxiliary cement well

A packer and cement slurry technology, which is applied in the directions of sealing/isolation, earthwork drilling, wellbore/well parts, etc., can solve problems such as capsule liquid leakage, packer pressure relief failure, damage, etc., to achieve benefit Effects of production and operation, protection of oil and gas layers, and resolution of interlayer interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Its technical scheme is: comprise the following steps:

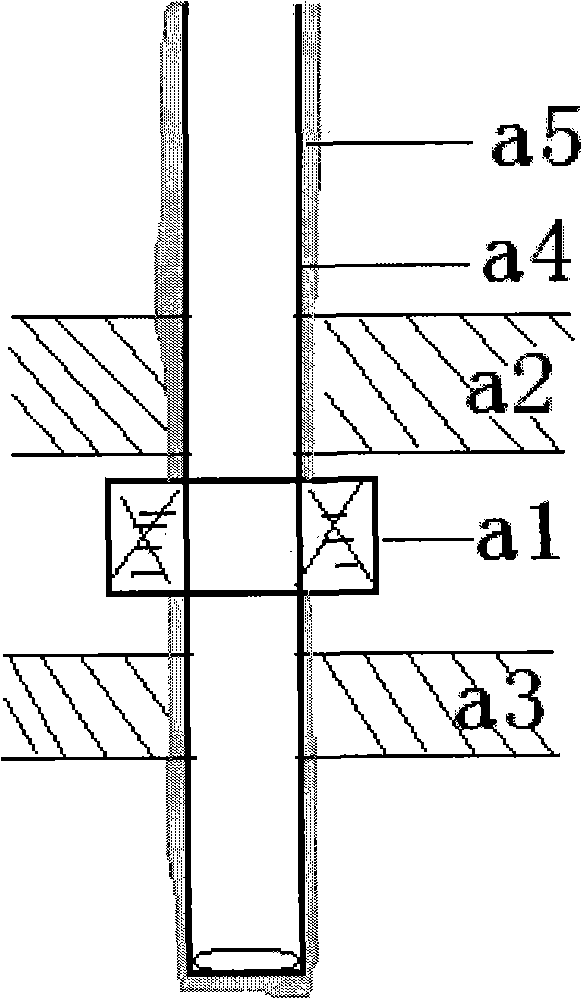

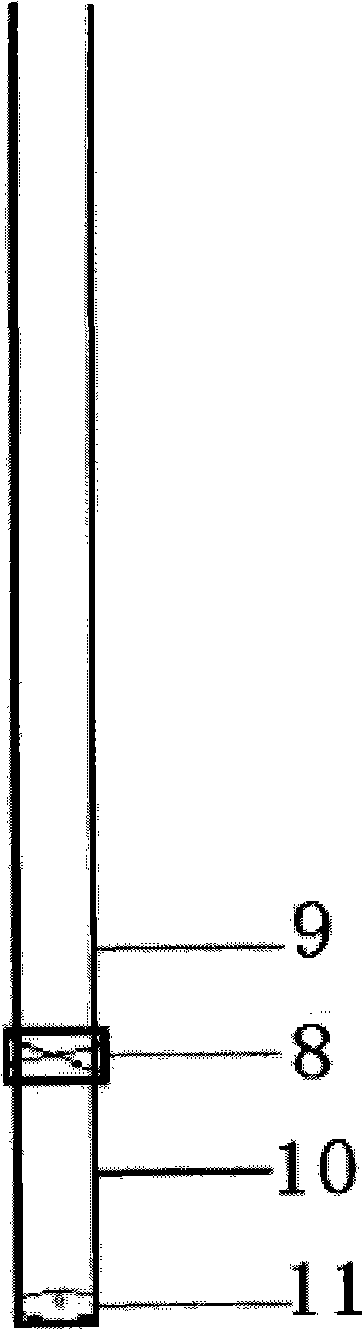

[0035] (1) Referring to accompanying drawing 3(a), an external packer 8 is set at the position where the wellbore profile needs to be isolated, and is connected in series with the casings 9, 10 and the fixed valve 11 to go downhole;

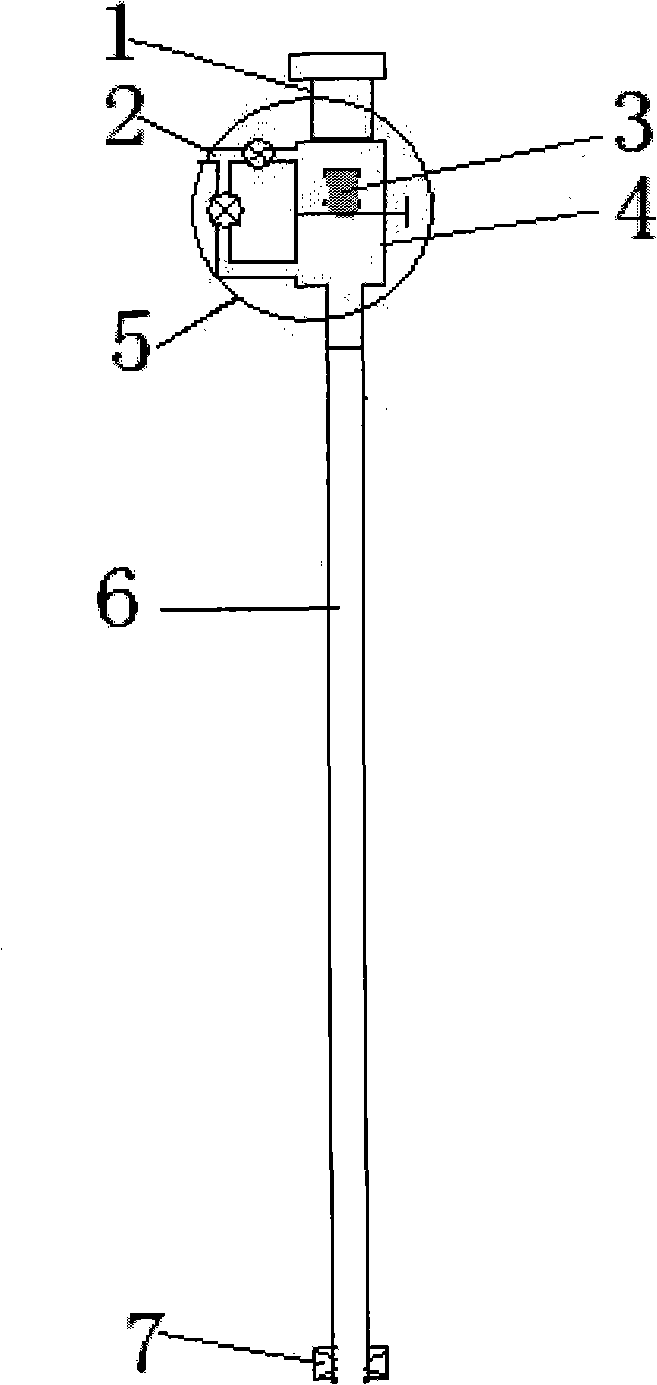

[0036] (2) Connect the cement slurry expansion sealer external packer to assist cementing tools, connect the cementing truck to the special cement head, and cement the well through the special cement head 5 and casing 9;

[0037] (3) Referring to the accompanying drawing 3(b), after passing through the cement head valve, cut the hollow rubber plug 7 from the bumping rubber plug 3 to the hollow rubber plug 7, and then go down together to bump the cementing valve 11.

[0038] (4) Referring to the accompanying drawing 3(c), untie the threaded connection between the special cement head 5 and the casing 9, lift up the cement slurry expansion sealer outer packer to assist the cementing too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com