Sliding block component of off-centering type transmission as well as clutch plate thereof

A transmission, eccentric technology, applied in the direction of transmission parts, friction transmission, belt/chain/gear, etc., can solve the problems of short service life of the clutch, increased size of the clutch disc, and insignificant effect, so as to prolong the service life. , The effect of increasing the contact point and improving the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

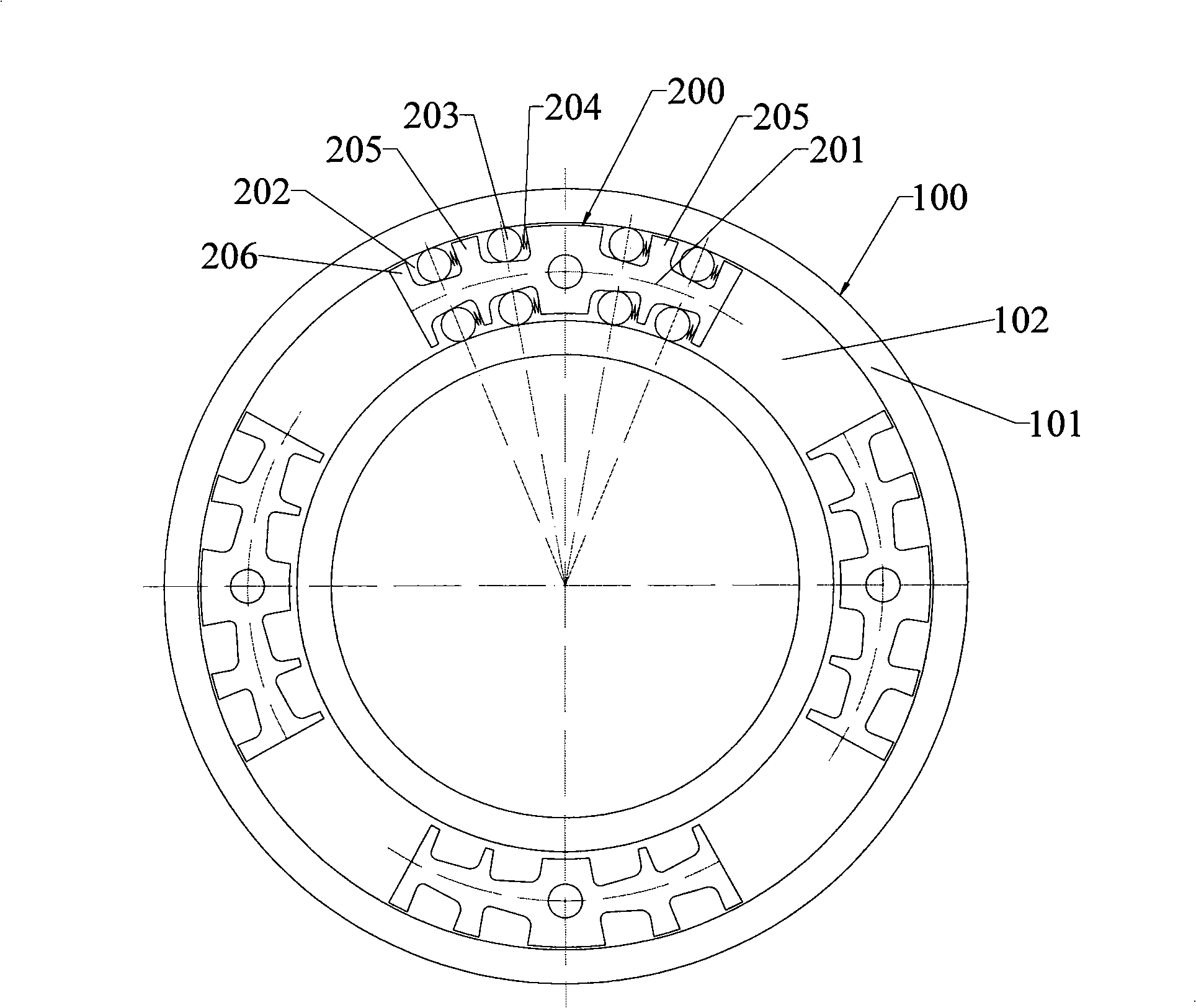

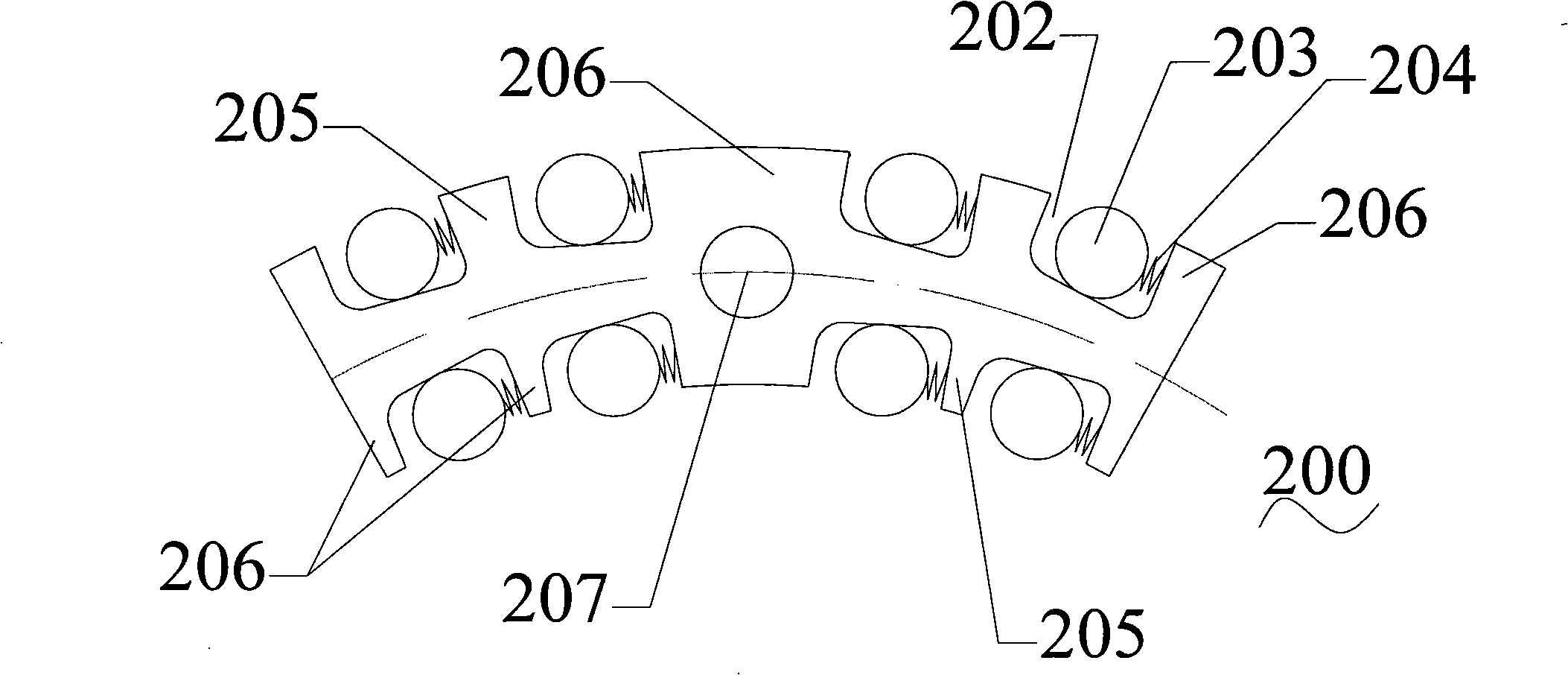

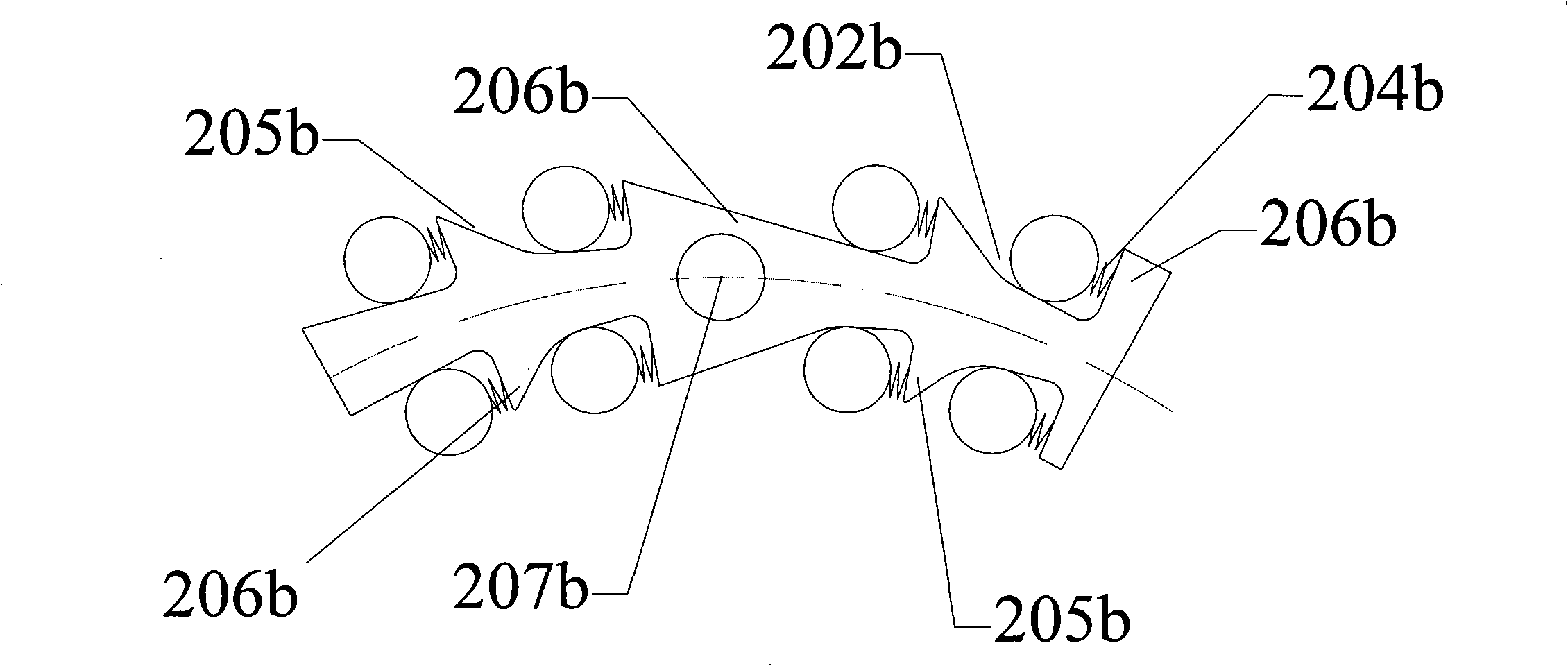

[0033] Such as figure 1 , figure 2 Shown is the slider assembly 200 of the present invention and the first embodiment of the clutch disc 100 using the slider assembly 200 , and the clutch disc 100 can be applied in an eccentric transmission.

[0034]The clutch disc 100 includes a disc-shaped body 101 and a slider assembly 200 disposed on the disc-shaped body 101 . The disc-shaped main body 101 is provided with an annular groove 102 for installing the slider assembly 200 therein. The structural form of the disc-shaped main body 101 can be such as Figure 2-4 The monolithic structure shown can also be as Figure 10 In the assembled structure shown, a rolling groove or raceway is formed on the side wall of the ring groove 102 for the sliding part of the slider assembly 200 or the guide part 206 of the slider body 201 to slide therein.

[0035] The slider assembly 200 includes a ring-shaped slider body 201 and multiple sets of plugging sets. There are at least three or more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com