Method and apparatus for testing surface defect

A defect detection and defect technology, applied in the detection field, can solve the problems of defect misjudgment, missed judgment, low detection accuracy, unfavorable labor saving, etc., to achieve the effect of avoiding misjudgment and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

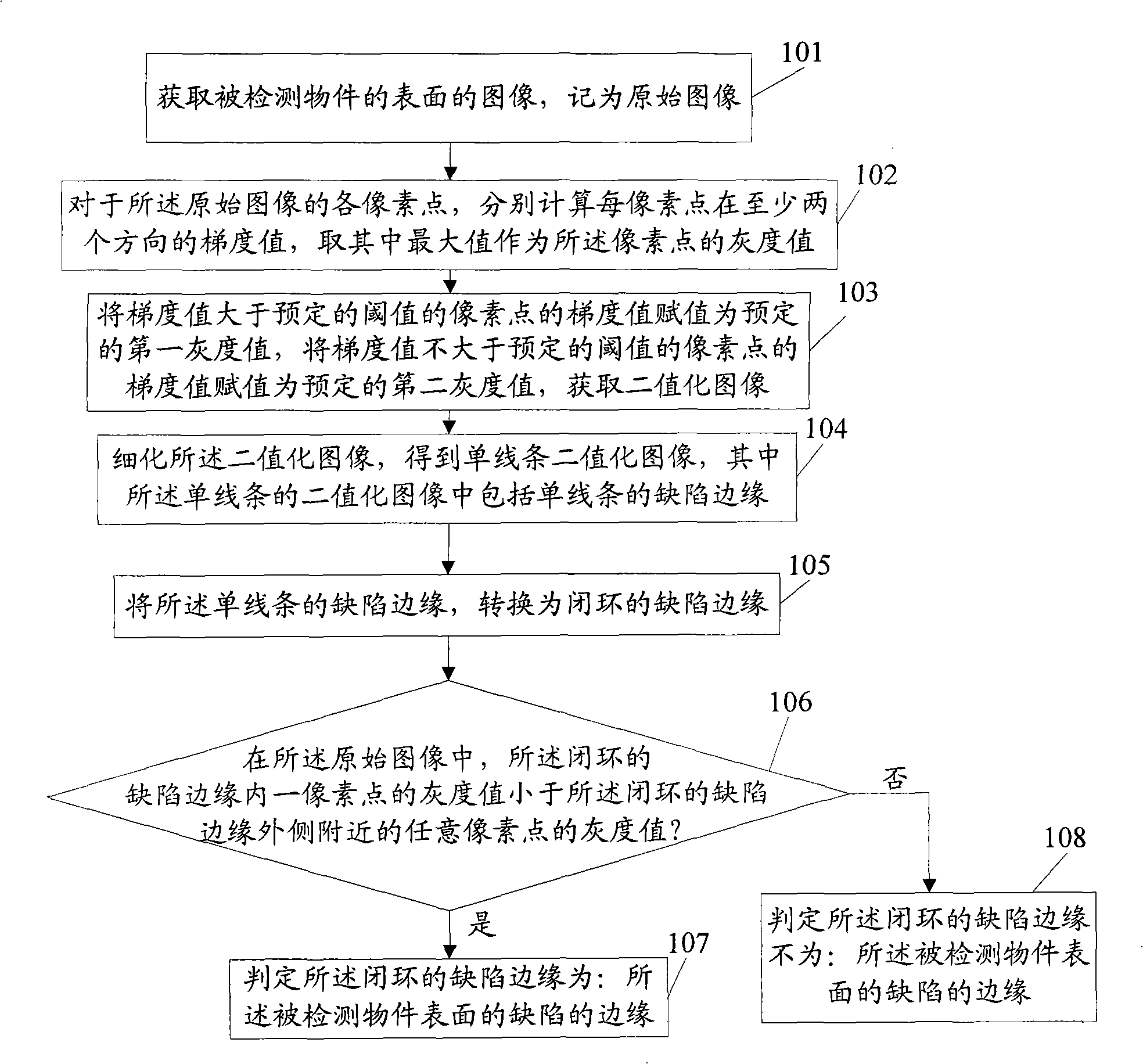

[0032] figure 1 It is a schematic flow chart of the surface defect detection method of this embodiment, as shown in the figure, the method includes:

[0033] Step 101: Obtain an image of the surface of the detected object, which is recorded as an original image.

[0034] Use the existing optical imaging equipment (such as video camera, camera, etc.) to obtain the optical image of the detected object, which is recorded as the original image, expressed as F(x, y), and the gray value of each pixel is recorded as: f(x, y), where x and y are the abscissa and ordinate of the pixel point respectively, the value range of x is 0 to ImagWidth, and the value range of y is 0 to ImagHeight.

[0035] For optical imaging, the gray value of a certain pixel on the image is larger because the point reflects more light to the camera, which is reflected on the surface of the detected object, so the point is relatively smooth, so the image of the detected object The change of the gray value can ...

Embodiment 2

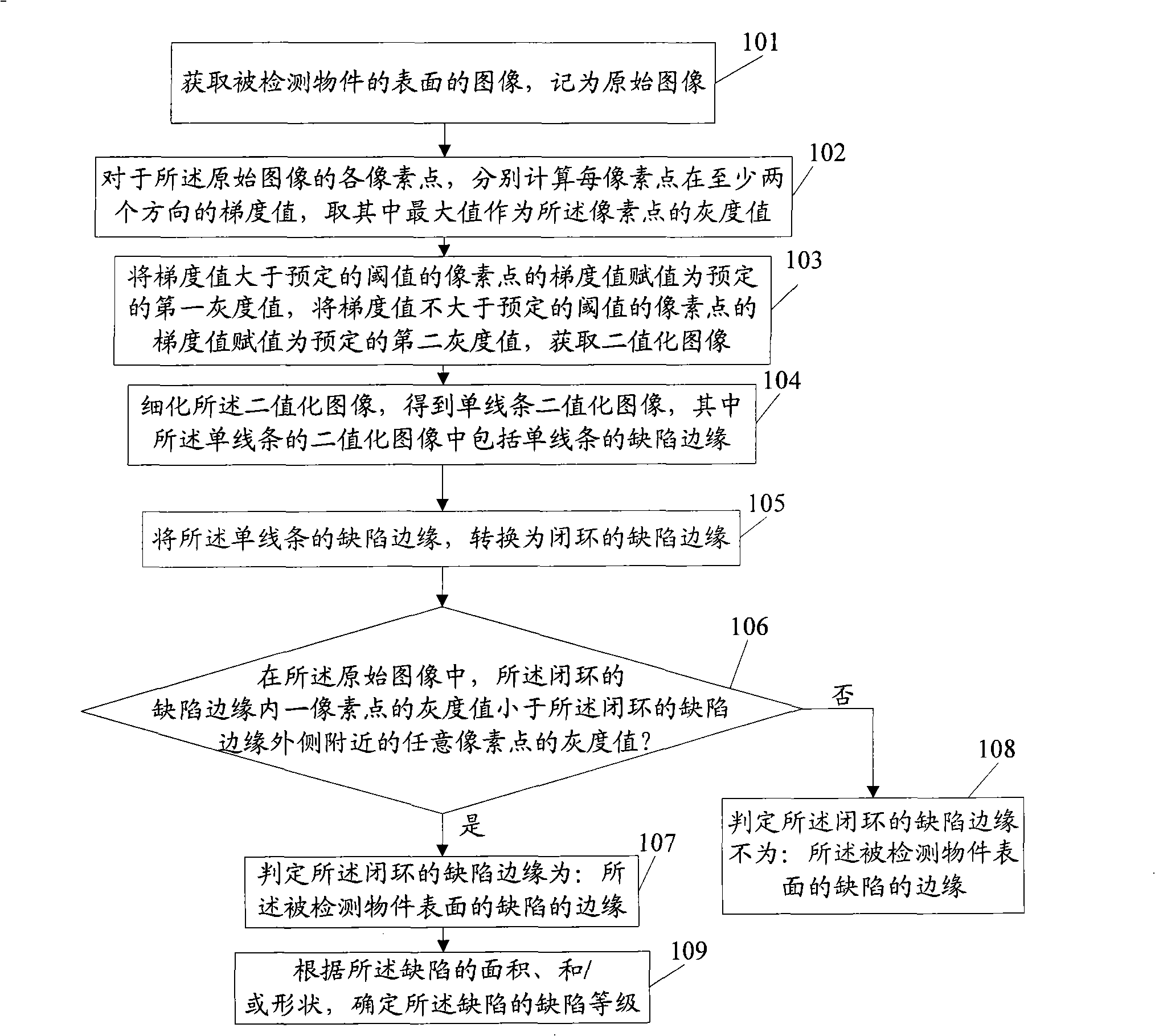

[0068] Figure 4 The schematic flow chart of the surface defect detection method provided in this embodiment, as shown in the figure, the difference between the method of this embodiment and the method of Embodiment 1 is that the method further includes step 109 after step 107 .

[0069] Step 109: Determine the defect level of the defect according to the area and / or shape of the defect.

[0070] Generally, in the process of industrial inspection, after the defect is detected, the defect can also be divided, and the defect can be processed accordingly according to the division, so after step 106, this step can also be performed:

[0071] After a defect is found, determine whether the defect is a point defect, a line defect, or a surface defect according to the shape of the defect (the shape of the edge of the defect in a closed loop), and / or to perform corresponding processing according to the defect level.

Embodiment 3

[0073] Figure 5 It is a schematic structural diagram of the surface defect detection device of this embodiment, as shown in the figure, the device includes:

[0074] The input unit 501 is used to input the image of the surface of the detected object, which is recorded as the original image.

[0075] For specific principles, refer to the description of step 101 in the embodiment.

[0076] The gradient image determination unit 502 is used to calculate the gradient values of each pixel in at least two directions for each pixel of the original image, and take the maximum value as the new gray value of the pixel to obtain the gradient image.

[0077] Preferably, the gradient image determining unit 502 calculates the gradient values of each pixel in 8 directions when calculating the gradient of each pixel in each direction, wherein the 8 directions are: from the pixel to the adjacent 8 direction of pixels.

[0078] For its specific principles, refer to the description of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com