Fluid bearing device and manufacturing method therefor

A fluid bearing, integrated technology, used in bearings, electromechanical devices, shafts and bearings, etc., can solve the problem of high processing costs, and achieve the effect of high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

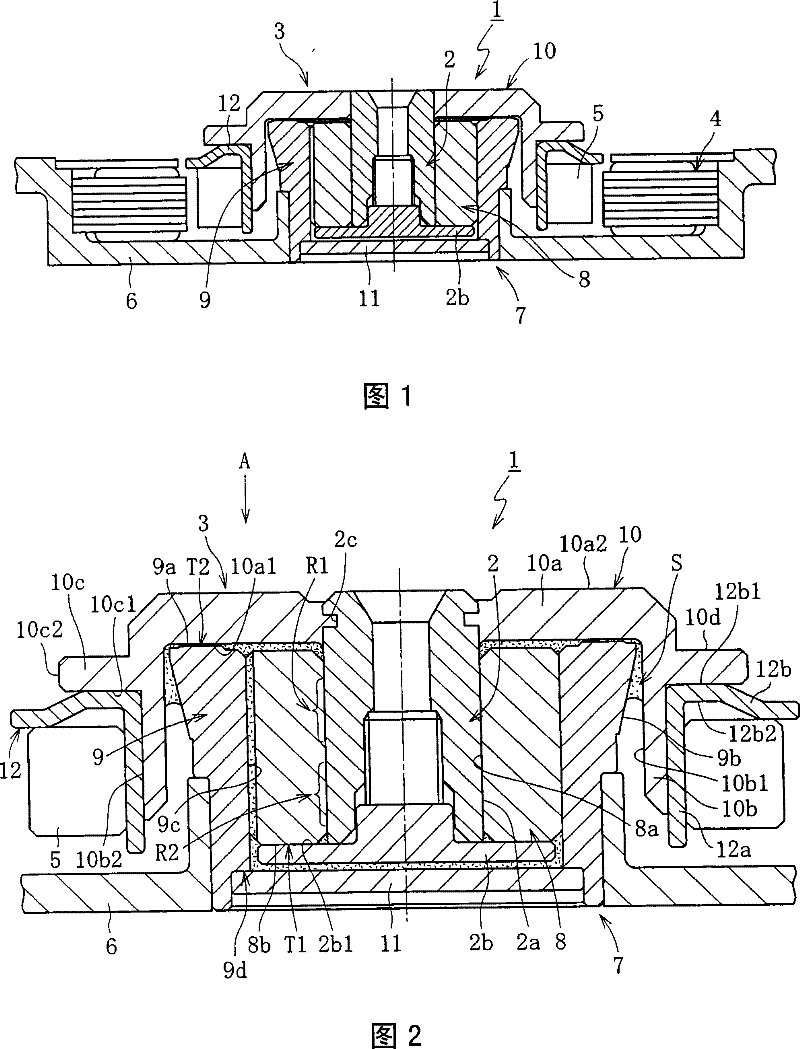

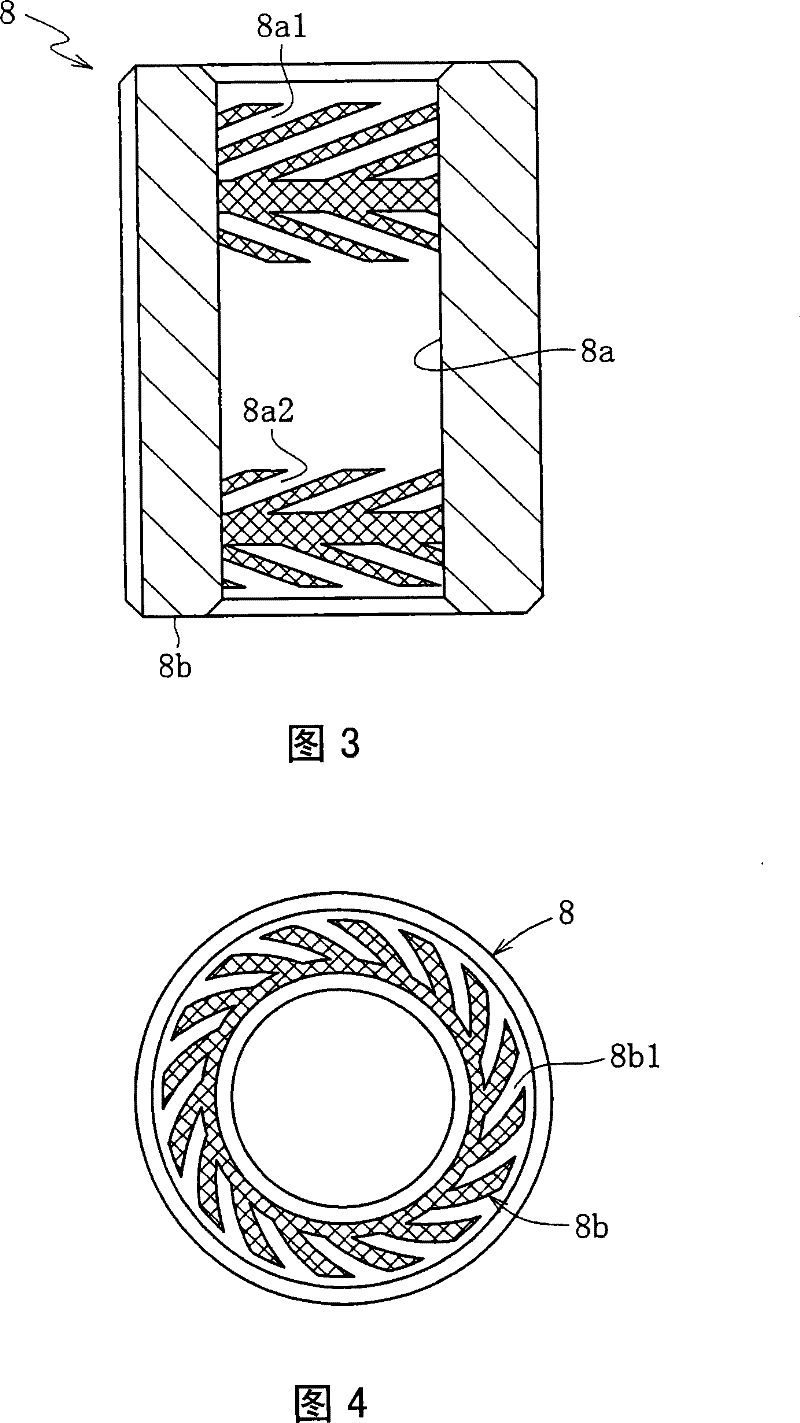

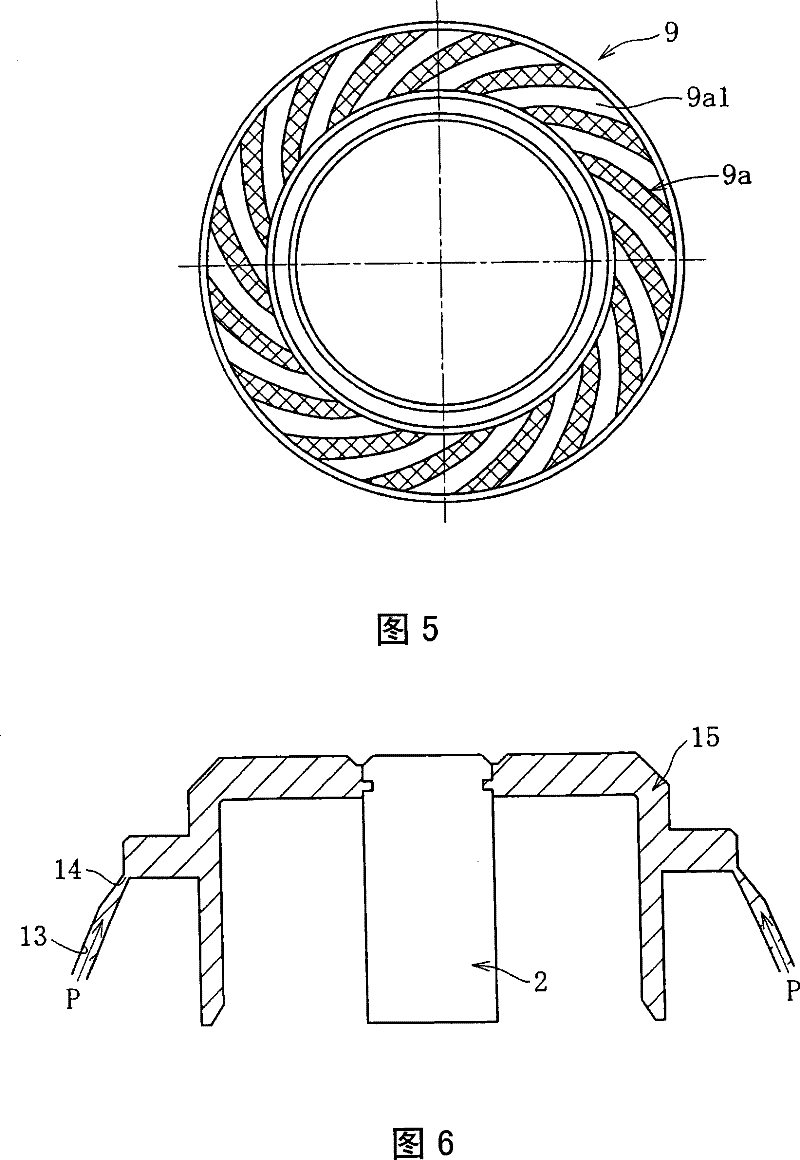

[0050] Embodiments of the present invention will be described below with reference to the drawings.

[0051] figure 1 A configuration example of a spindle motor for information equipment incorporating a fluid bearing device 1 according to an embodiment of the present invention is schematically shown. This spindle motor is used in a disk drive device such as an HDD, and includes a fluid bearing device (dynamic pressure bearing device) 1 that relatively rotatably supports a rotating member 3 having a shaft member 2 and a hub 10 in a non-contact manner. Stator coils 4 , rotor magnets 5 and brackets 6 facing each other with a gap. The stator coil 4 is mounted on the bracket 6 , and the rotor magnet 5 is fixed to the hub 10 via the yoke 12 . The bearing member 7 of the fluid bearing device 1 is fixed to the inner periphery of the bracket 6 . In addition, the hub unit 10 (not shown in the figure) holds one or a plurality of disks as information storage media. In the spindle mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com