Furniture and manufacturing and mounting thereof

A furniture and installation method technology, applied in the field of furniture, can solve problems such as unfavorable standardized production and quality control, inconvenient cleaning and sanitation, easy damage to customer floors, etc., and achieves the effect of avoiding righting difficulties, saving materials and small costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

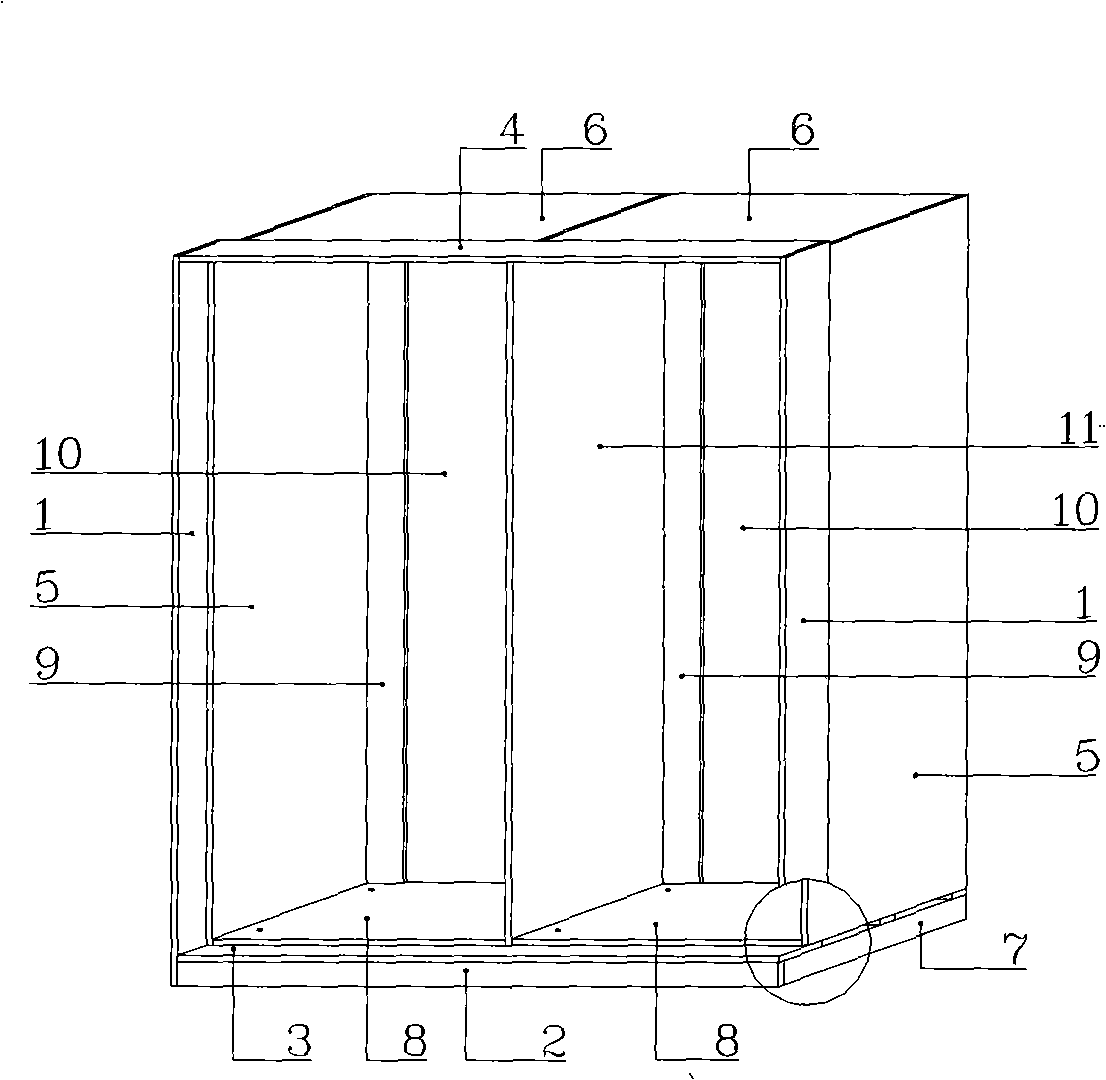

Embodiment 1

[0022] When one side of the side panel 5 of the cabinet body is completely covered by the wall, when designing the width of the entire cabinet body, an appropriate space between the side panel 5 of the cabinet body and the wall should be reserved, which should generally be the thickness of the side panel decoration component 1 , or slightly larger than 2-5mm. Example: When the width of cabinets such as wardrobes, bookcases, and wine cabinets to be installed is 2000mm, if the thickness of the side panel decoration component 1 is 20mm, and the number of side panel decoration components 1 is 2 pieces, the total width of the cabinet should be designed as 1950mm to 1960mm. The width of the side panel decoration assembly 1 is: the width exposed outside is the light-seeing surface, plus the fixed width of the space between the cabinet side panel and the wall inserted into the cabinet side panel 5. The color of the side panel decoration assembly 1 can be customized according to the r...

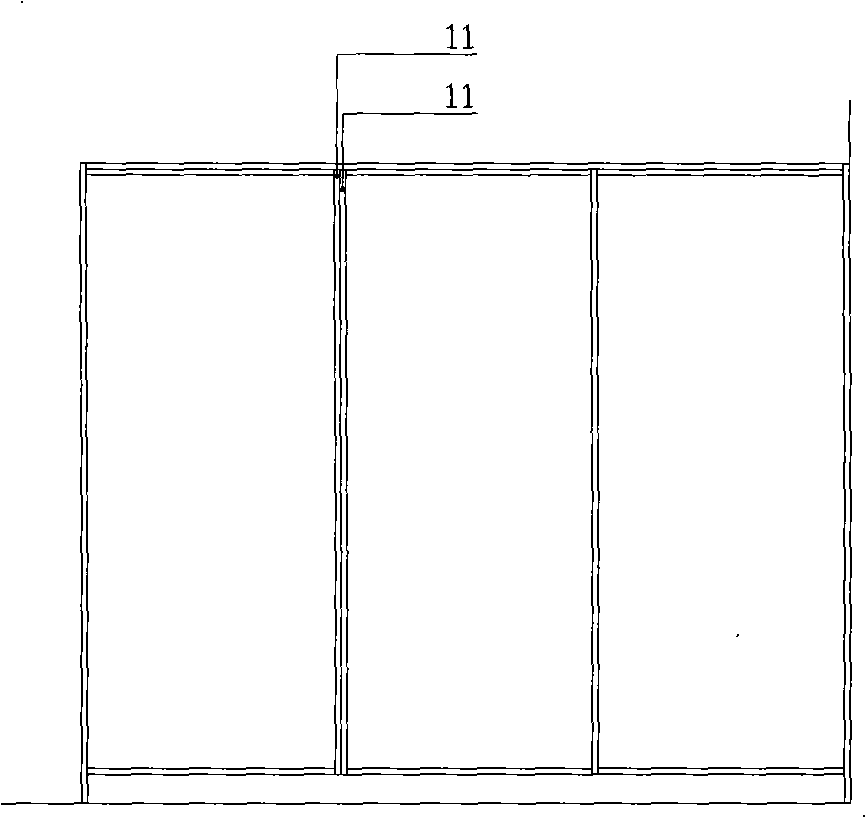

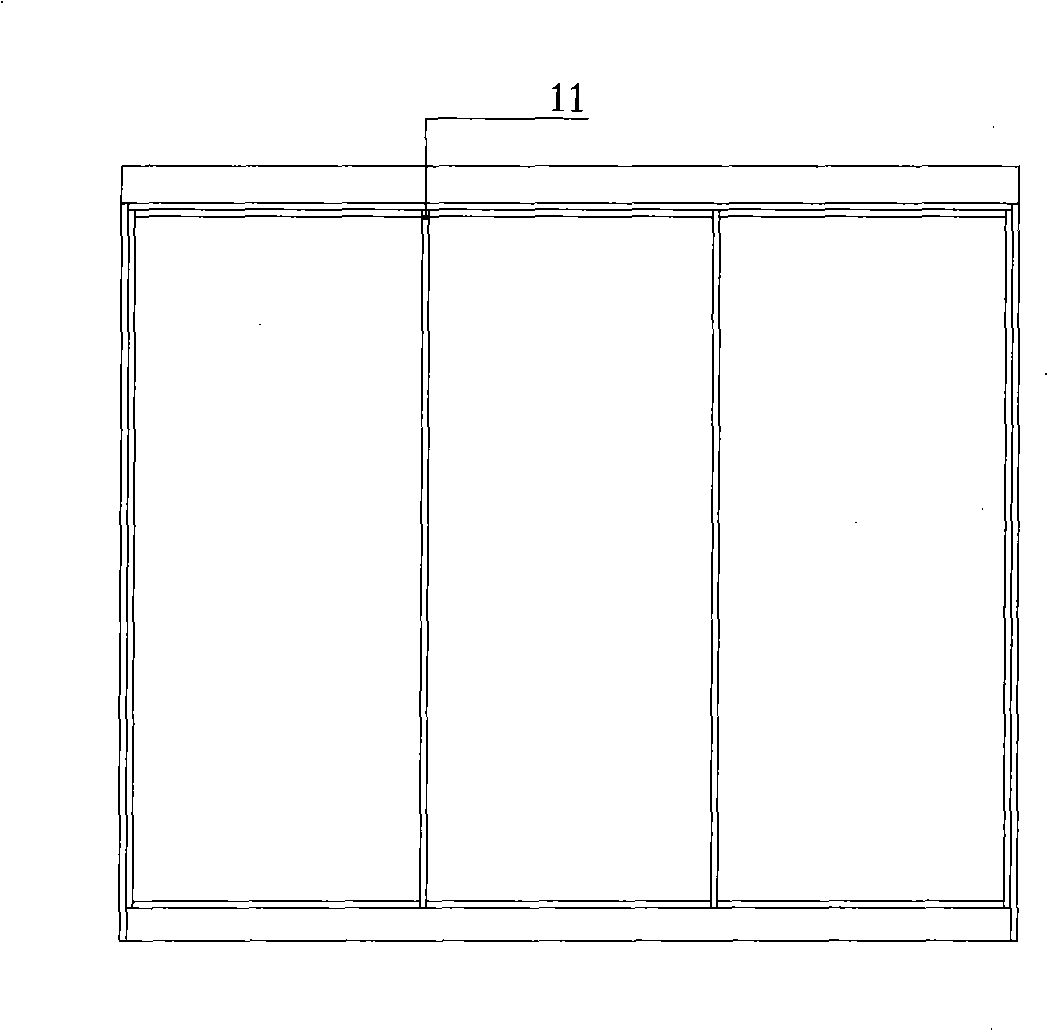

Embodiment 2

[0025] When the cabinet body is a partition cabinet, because the backboard 10 is not blocked by the wall, it may not only play the role of the backboard of the cabinet body, but also play the role of the wall, and also produce the effect of decorative components. Directly nailed or glued to the bone of the backboard, and the color of the backboard can be customized according to customer requirements.

Embodiment 3

[0027] (1) If the side panel of the cabinet is against the wall on one side, the installation steps are as follows:

[0028] ① Prepare and adjust the base.

[0029] Before installing the base 7, you should pay attention to the following items: When installing the base 7, you need to place slats and other objects under it. The specific height of the pads depends on the situation. -60mm; if the cabinet is a composite floor, no backing plate is needed under the base 7, but the ground must be leveled before installation. After the ground is leveled, if you need to fine-tune the height of the base 7, you can place a 2-5mm high pad objects; if the ground where the cabinet is located is tiles, the base 7 can be placed directly on the tiles, or a 2-5mm high cushion can be placed; if the length of the cabinet exceeds 2.4 meters, two bases need to be set. The planes of the two bases and the joint surface where the lower decoration component 2 is installed must be leveled, and the two b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com