Die for injecting and blowing plastic hollow container forming container by one-step method and single working-station, and application thereof

A technology of blow molding and empty containers, which is applied in the field of plastic processing, can solve problems such as difficult product quality assurance, difficult mold processing, and high system configuration requirements, and achieve easy product quality assurance, high production automation, and simple operation and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

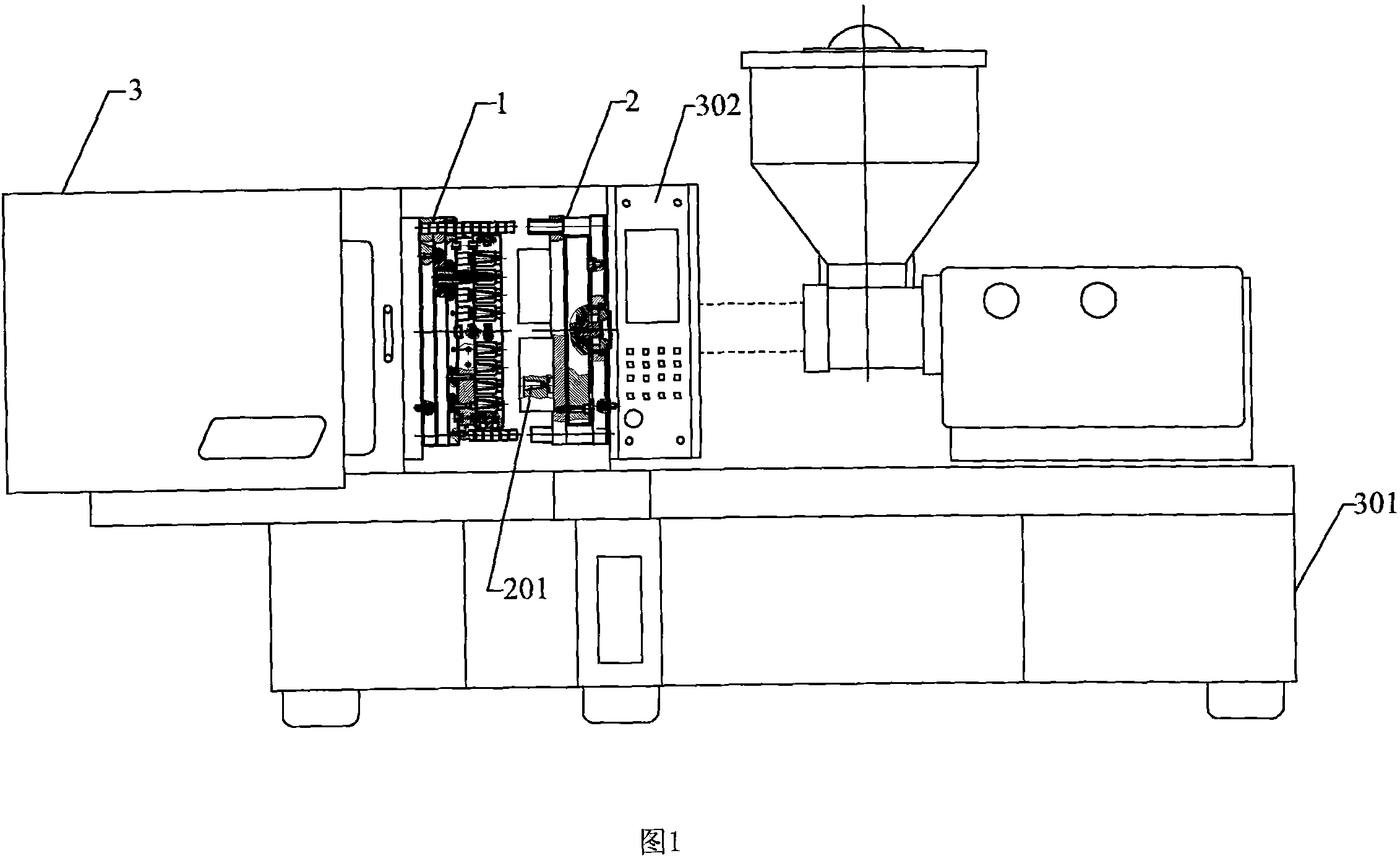

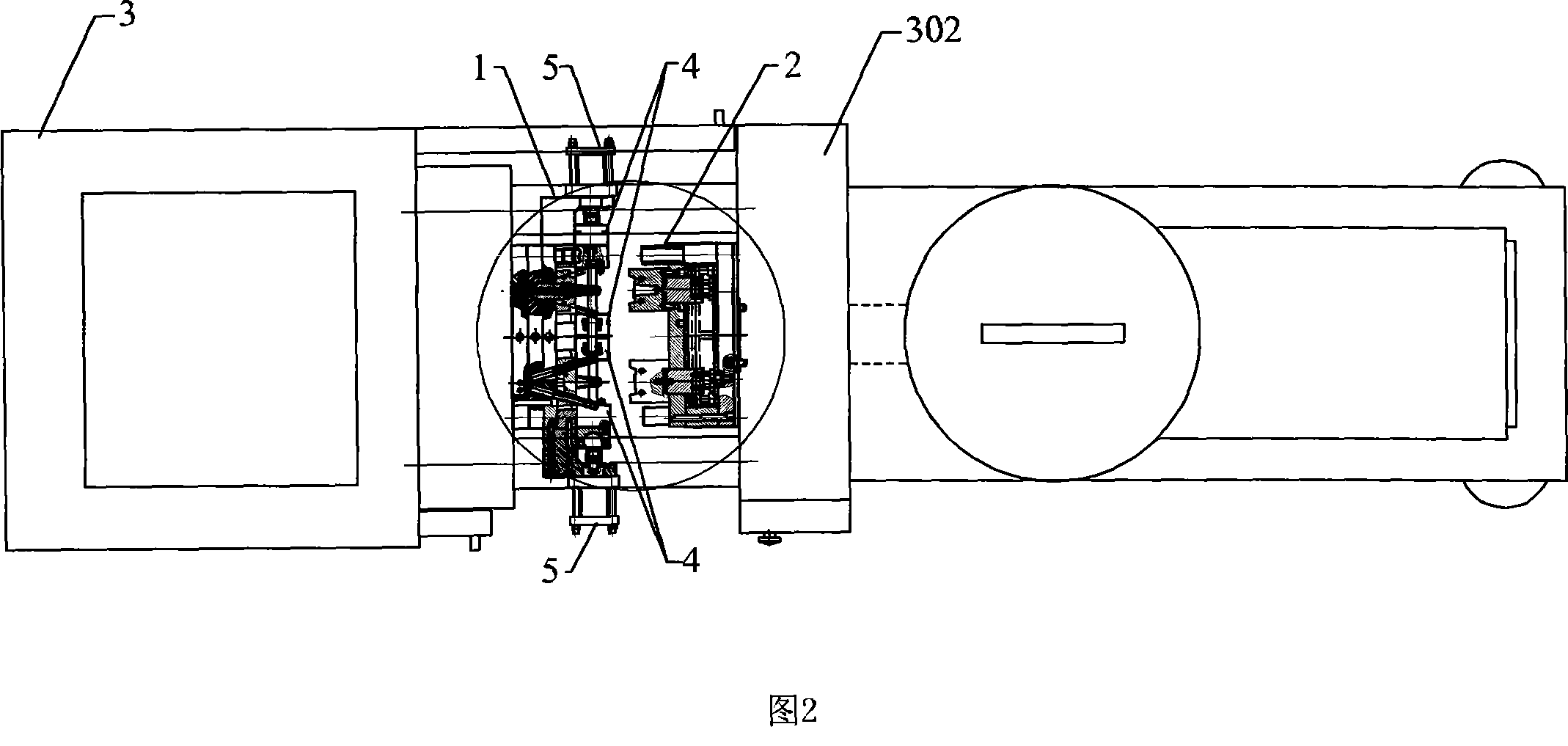

[0040] Such as figure 1 , 2 As shown, the invention includes injection mold assemblies and blow mold assemblies.

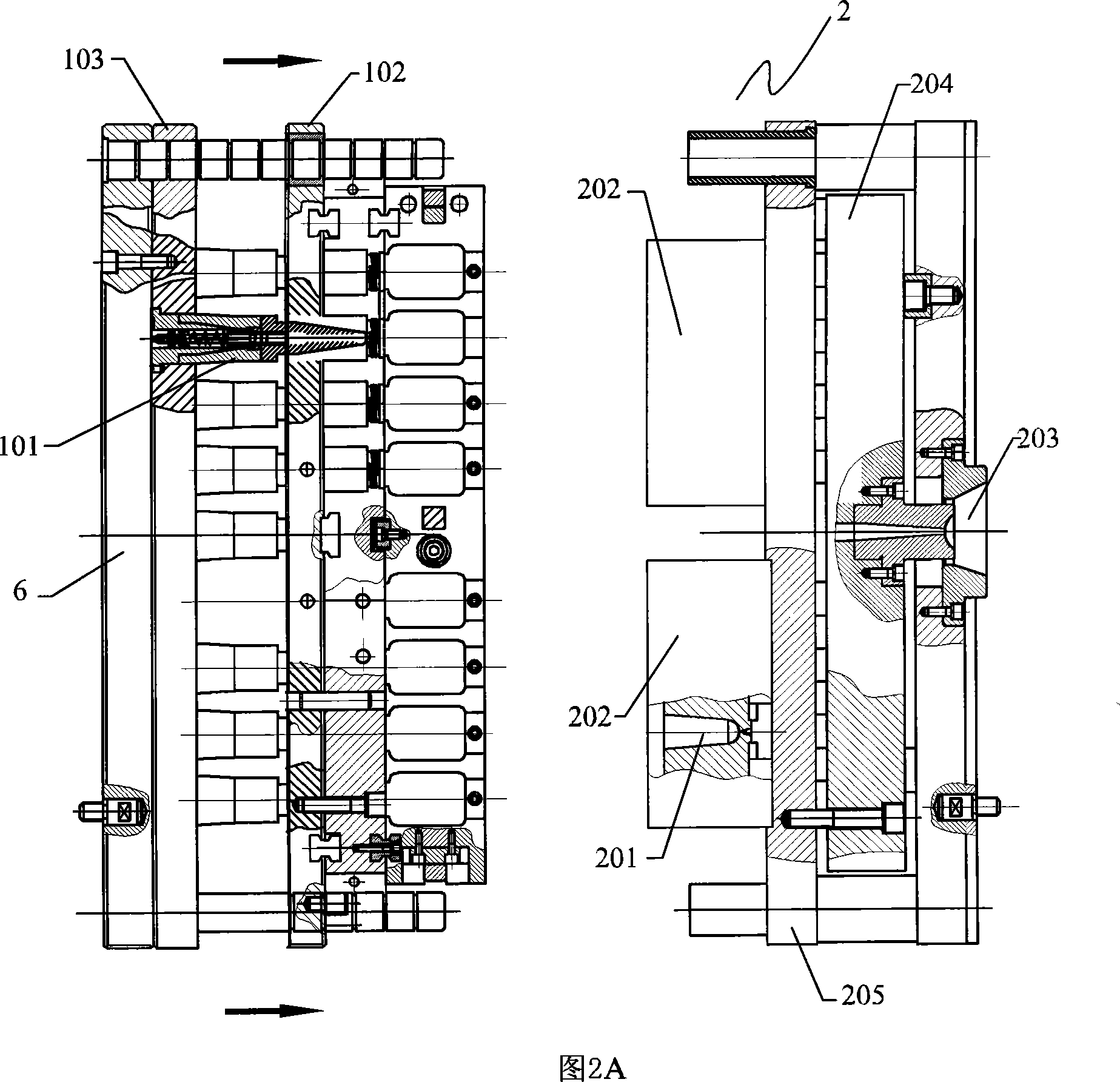

[0041]The injection mold assembly includes a movable mold 1 and a fixed mold 2 arranged in left and right directions. The movable mold 1 is controlled by a group of driving mechanisms to move left and right in the horizontal direction, so that it can be opened and closed with the fixed mold 2.

[0042] The fixed mold 2 includes a sprue sleeve 203 , a hot runner 204 , and a preform cavity plate 205 . The hot runner 204 is an evenly divided open runner. A row of longitudinally arranged preform cavities 201 is arranged on each raised preform cavity plate 202 provided on the fixed mold 2 , and the bottom of the preform cavity 201 is provided with a runner injection port. The fixed mold is fixedly connected with the fixed injection molding end 302 of the ordinary injection molding machine. The preform cavity plate is in a convex shape, so as to facilitate the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com