Pressing machine slide block

A press and slider technology, applied in the field of presses, can solve the problems of large deformation of the bottom surface of the slider body, poor support effect, indirect transmission, etc., and achieve the effect of weight reduction, small stress and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

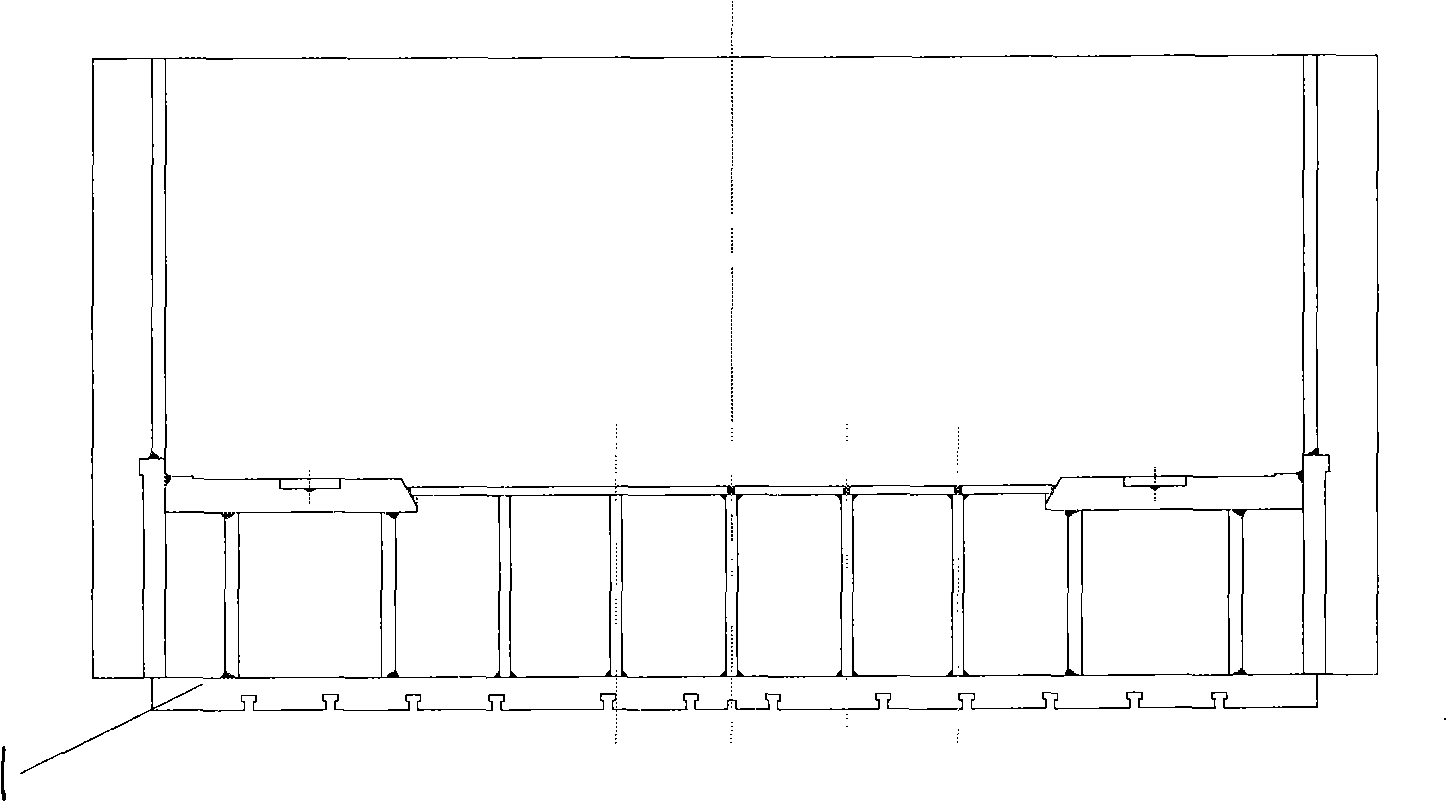

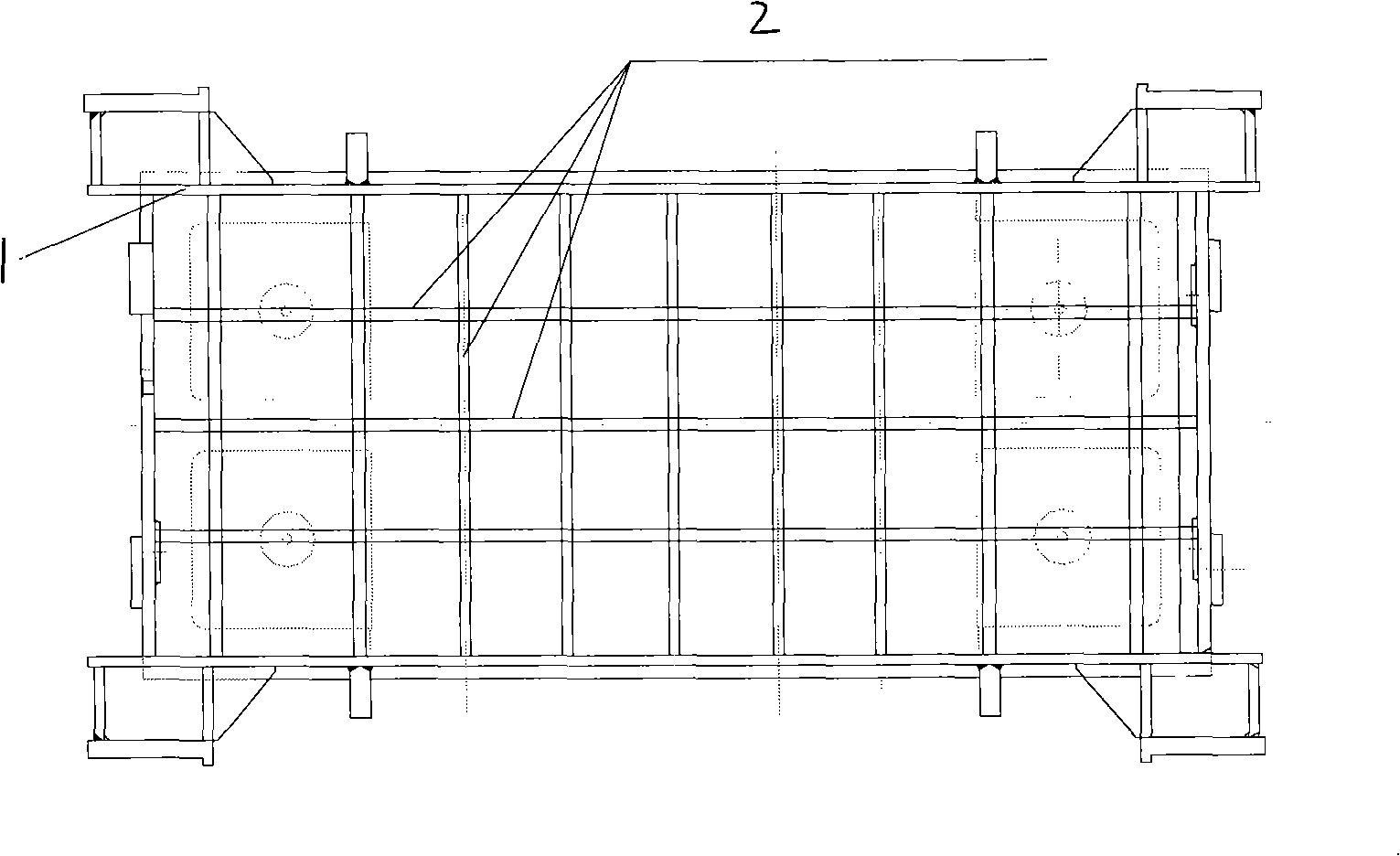

[0012] Accompanying drawing is a kind of specific embodiment of the present invention.

[0013] The press slide block of the present invention comprises a bottom plate 1 with ribs 2 inside, and the ribs are in the shape of a criss-cross network. The mesh structure layout of the rib plate 2 increases the internal support of the slider body and greatly reduces the thickness of the bottom plate 1 and the main rib plate. 1 / 3 thinner. Adding 2 to 3 ribs in the left and right directions and the front and rear directions in the original structure can form a denser network structure inside the slider and improve the supporting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com