Rotary orbit shuttle device

A technology of steering mechanism and slewing bearing, which is applied in the field of steering devices of material handling vehicles, can solve the problems of increasing automatic control, large size, affecting work efficiency, etc., and achieves the effects of flexible turning, small turning radius and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

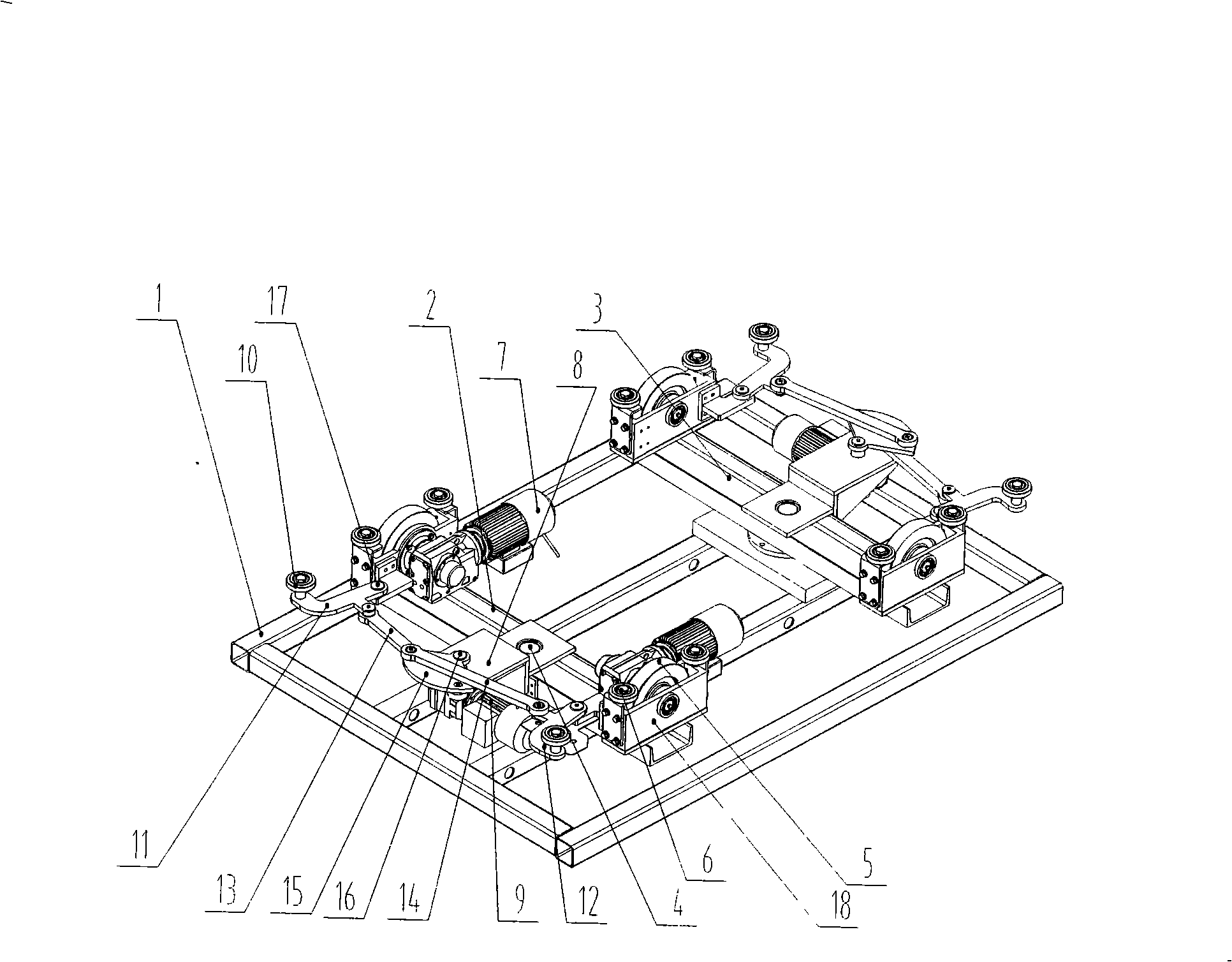

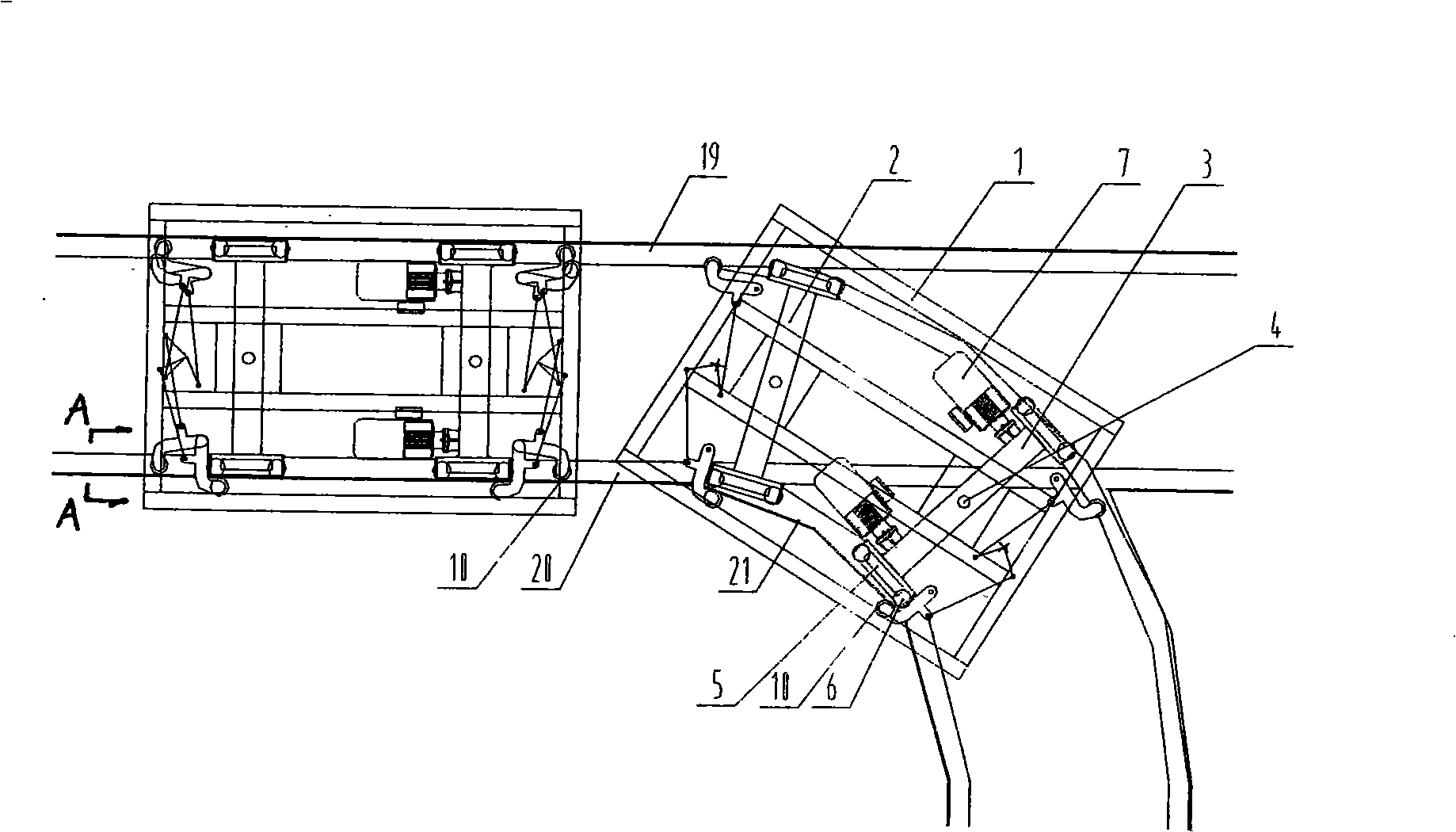

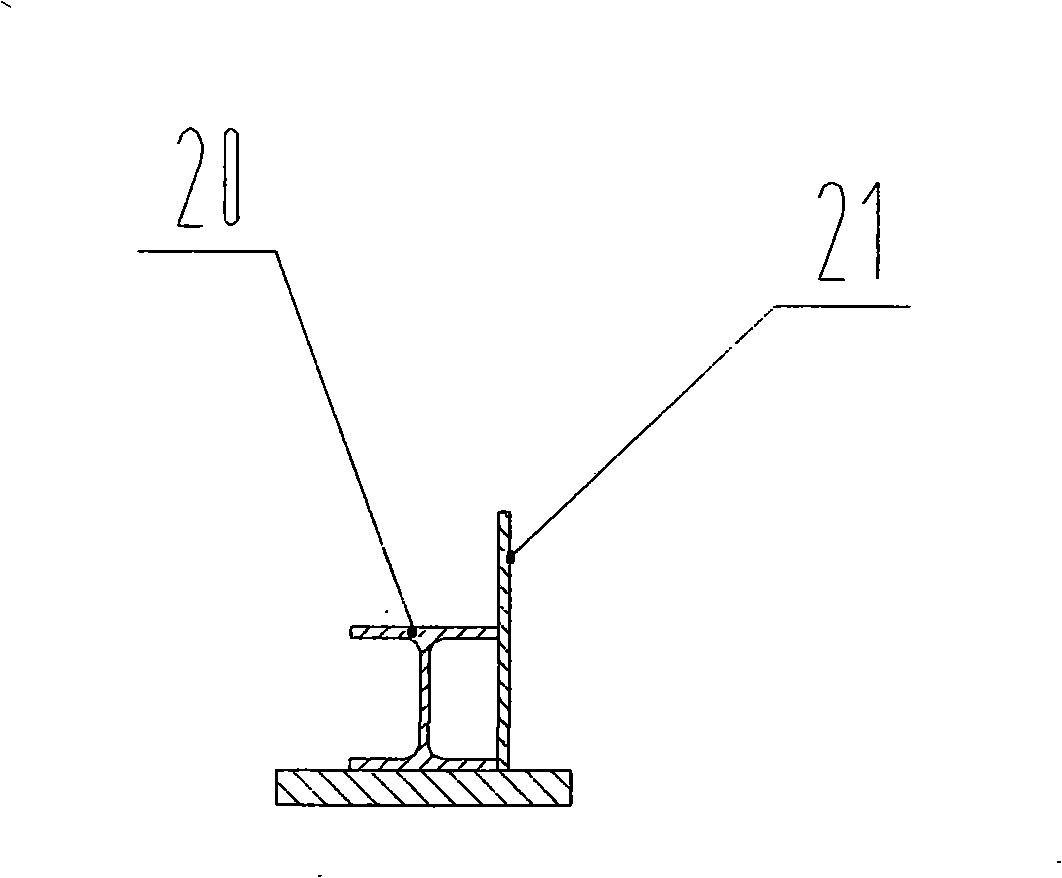

[0012] Such as figure 1 As shown, the present invention comprises a support frame 1, on the support frame, a horizontal front support 2 and a rear support 3 are connected and installed through a slewing support bearing 4, and a steering mechanism is installed on the outside of the front support 2 and the rear support 3. The traveling wheels 5 driven by the traveling motor 7 are respectively symmetrically installed, and the traveling wheels 5 are installed in the wheel seat 18; Steering motor 9 drives and can rotate along the rotating disk 15 of axle center 16, the link mechanism 13,14 that is hinged on the rotating disk, the pivoting arm 11,12 that is hinged at connecting rod two ends, and one end of pivoting arm is installed on the fixed shaft 17, The other end is equipped with movable guide wheel 10. Fixed guide wheel is installed in the both sides of wheel base 18. Two travel motors 7 are fixed on the inboard of wheel seat. Different conveying carriers, such as roller co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com