Packing machine and packing method for filling bags

A packaging machine and filling technology, which is used in the field of bulk material filling valve bags, filling bags wrapped in thermoplastic plastics, and can solve problems such as irrelevance of sealing devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

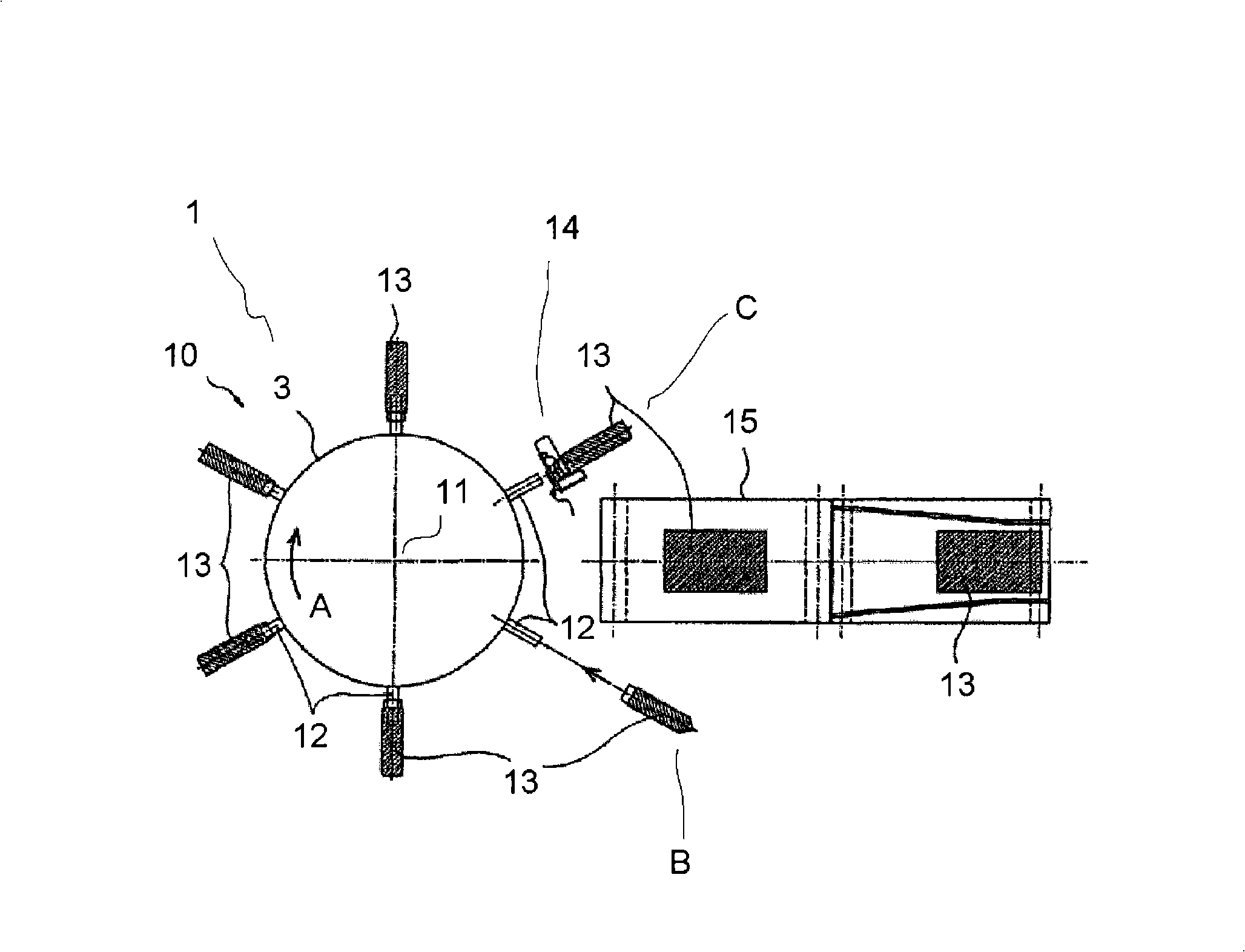

[0034] figure 1 A schematic top view of a packaging machine 1 is shown, which is designed as a rotary filling machine and comprises a housing 3 and a total of six filling nozzles 12 which are distributed uniformly over the circumference.

[0035] and figure 1 As shown, the packaging machine 1 according to the invention may comprise a greater or lesser number of filling nozzles. In the case of a rotary configuration, it is preferred to use more than two filling nozzles, preferably 6, 8, 10, 12 or 16 filling nozzles. In addition, other different numbers are also contemplated.

[0036] in such as figure 1 In the case of the packaging machine 1 shown, a bag, in particular designed as a valve bag 13 , is placed on the filling spout 12 at the placement position B. Although manual placement is possible, placement is preferably by means of a separate automatic feeder (not shown) which deposits or pushes the valve pocket 13 onto the filling nozzle 12 .

[0037] Each filling nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com