Double-tensioning rotary kiln graphite sealing device

A graphite sealing and rotary kiln technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of leakage, human injury, etc., achieve uniform wear, small air leakage coefficient, and achieve the effect of radial sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

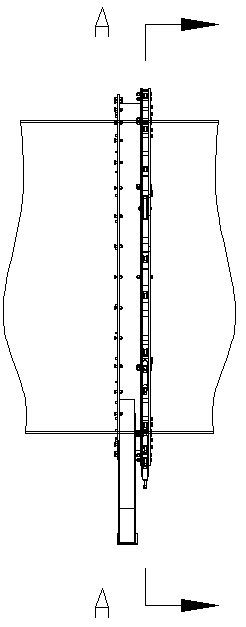

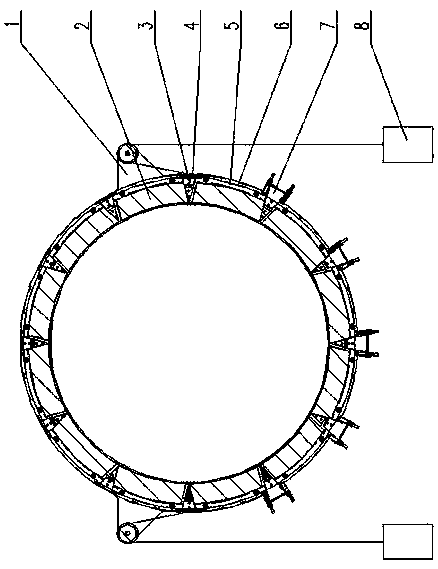

[0019] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

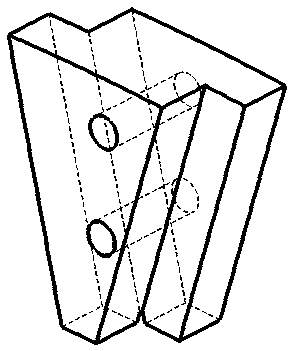

[0020] As shown in the figure, a double-tensioning rotary kiln graphite sealing device of the present invention includes a sealing frame 1, the sealing frame 1 includes a supporting cylinder and an installation cylinder, the installation cylinder is arranged at one end of the support cylinder, and the installation cylinder The main body of the body is set as two parallel circular rings, lugs are respectively arranged at the corresponding positions on both sides of the two parallel circular rings, fixed pulleys are installed between the two opposite lugs, and the sealing frame 1 is installed on the rotary kiln barrel The body needs to be sealed. On the middle circumference of the two parallel circular rings of the sealing frame 1, wedge blocks 3 are evenly spaced and fixed, and an arc-shaped graphite block 2 is installed between eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com