Manufacturing jig and manufacturing method for moving-iron unit square iron

A manufacturing method and moving iron technology, applied in manufacturing tools, auxiliary devices, laser welding equipment, etc., can solve problems such as low production efficiency and poor product quality, and achieve the effects of good applicability, good quality, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

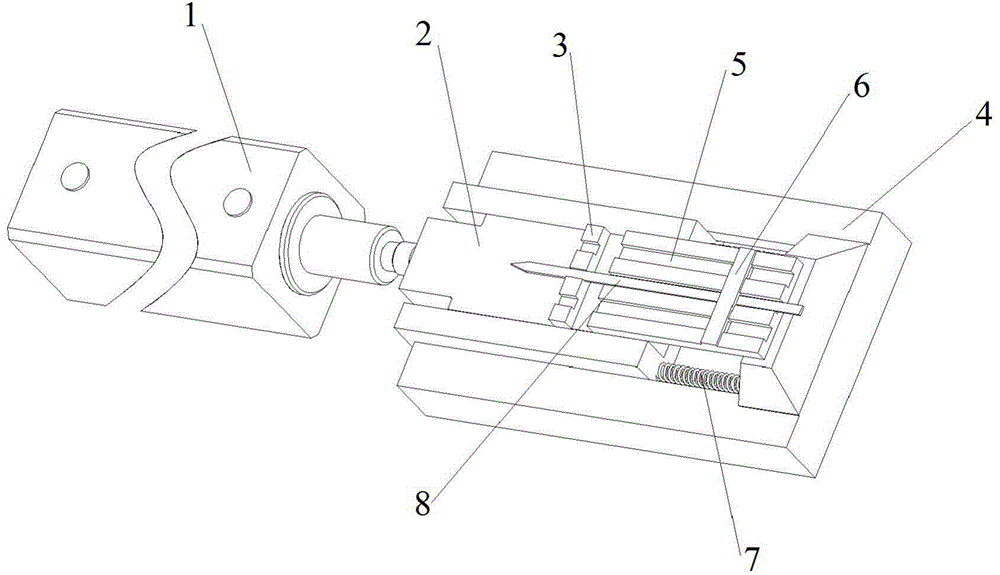

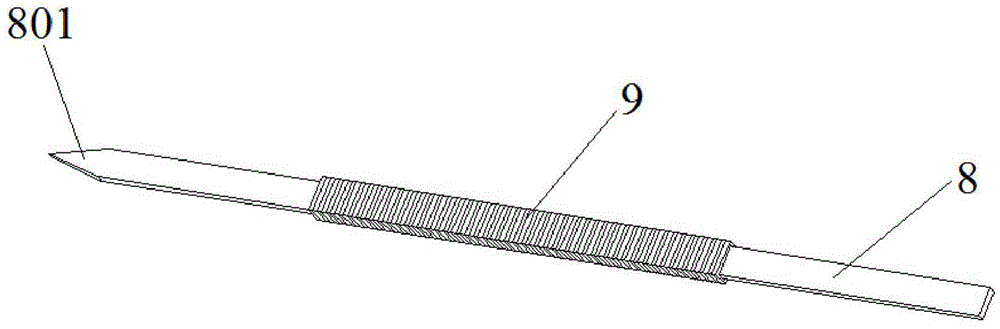

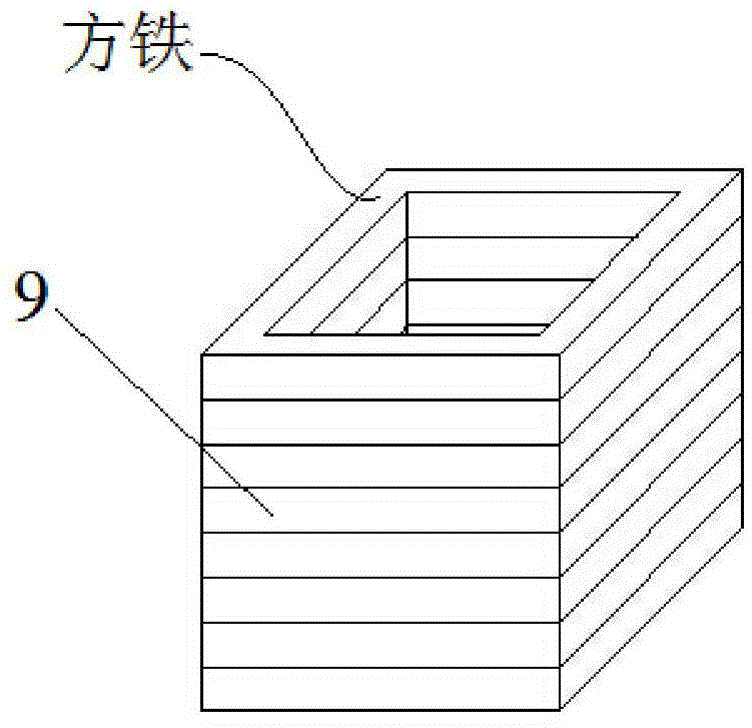

[0039] combine figure 1 and figure 2 , a manufacturing jig for moving iron unit square iron in this embodiment includes a cylinder 1, a slider 2, a slider 4 and a fixed core 8, the cylinder 1 is connected to the slider 2, and the slider 2 and the slider 4 are slidably matched , under the action of the cylinder 1, the slider 2 can slide in the slider 4; the slider 2 is fixedly provided with a push block 3, the rear end of the slider 4 is fixedly provided with a positioning plate 5, and the positioning plate 5 is provided with a stopper 6 , the push block 3 and the positioning plate 5 are respectively provided with positioning grooves on the same straight line, the stopper 6 is provided with a positioning hole on the same line as the above-mentioned positioning groove, the positioning groove on the push block 3 and the stopper 6 The size of the positioning hole on the positioning plate 5 is slightly larger than the size of the fixed core 8, which is convenient for the install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com