Feeding device for cylinder-shaped sewing machine

A feeding device and sewing machine technology, applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of round cloth damage, round cloth being caught between the roller and the endless belt, etc., to prevent tension increase Large, damage-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

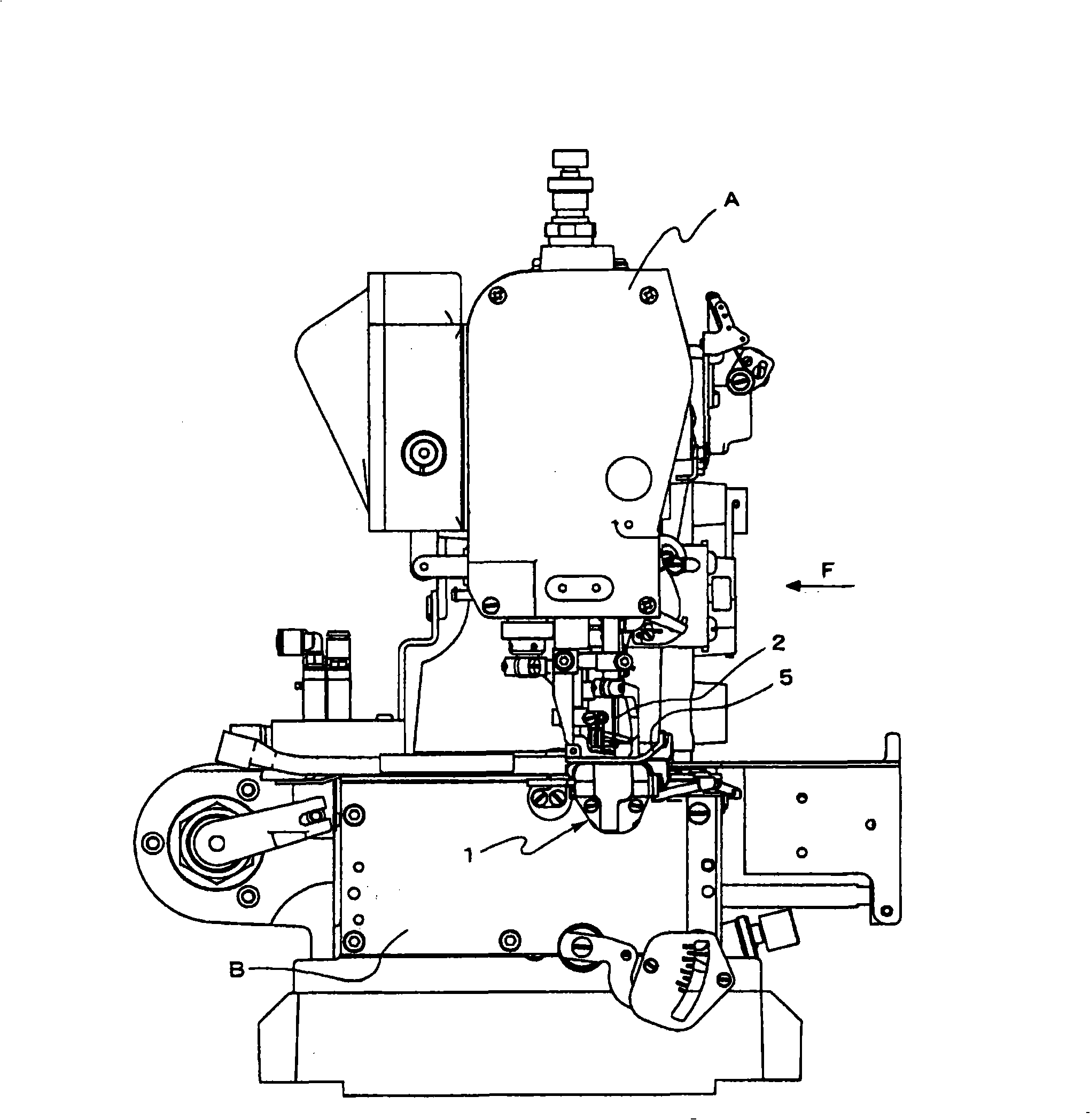

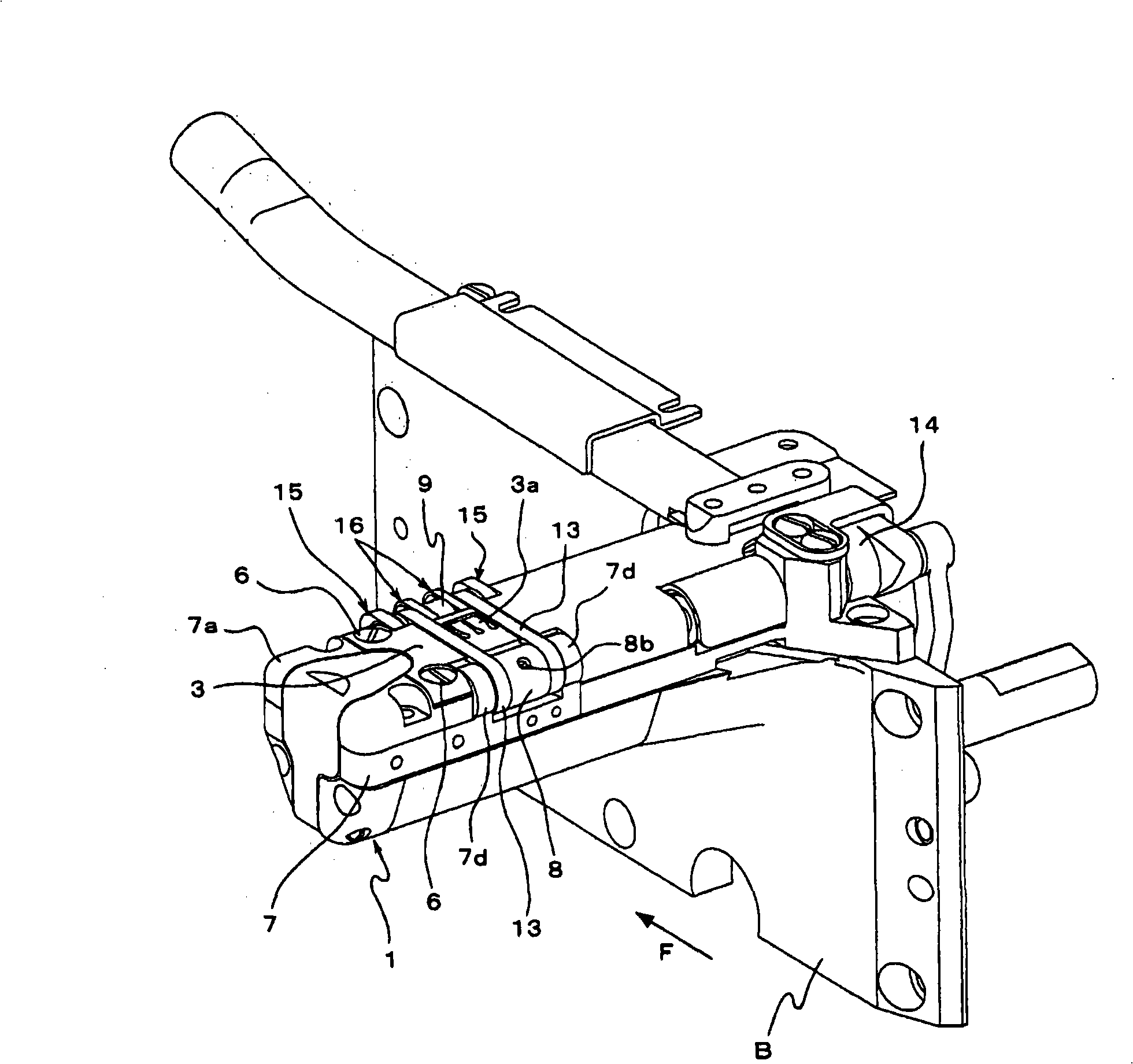

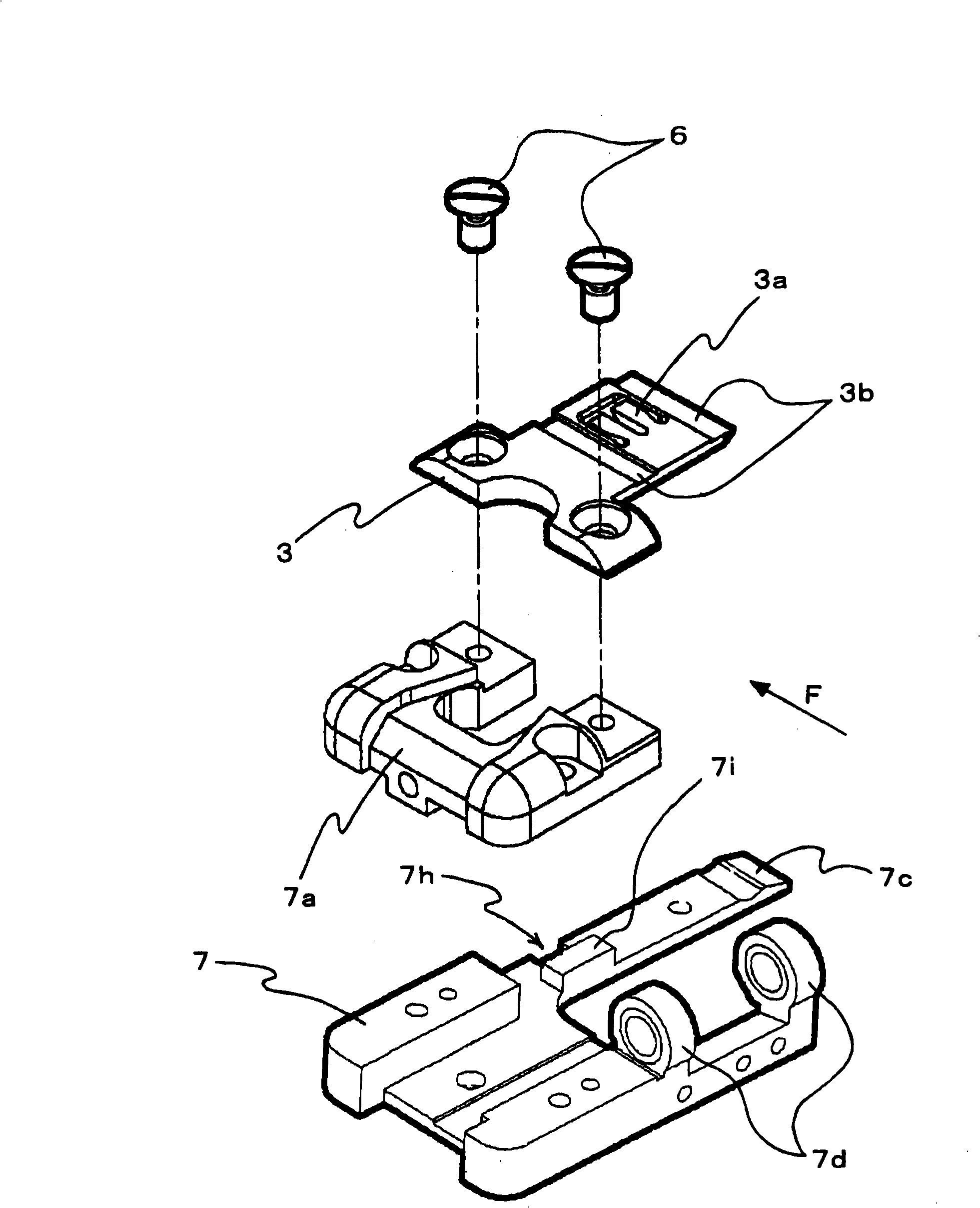

[0028] Embodiments of the present invention will be described below with reference to the drawings. The cylindrical frame 1 protrudes from the base B of the sewing machine, and the needle plate 3 arranged on the cylindrical frame 1 is under the push member 5 supported on the front end of the arm A of the sewing machine. The needle plate claw 3a of the needle plate 3 is figure 2 Extending in the cloth feeding direction F as shown, the needle 2 disposed at the front end of the sewing machine arm intermittently penetrates around the base of the needle plate claw 3a. Such as image 3 As shown, the needle plate 3 is fixed on the mounting part 7a of the bracket 7 by screws 6 . Such as Figure 4 As shown, the bracket 7 is detachably fixed on the cylindrical frame 1 through the pin 7b and the protruding piece 7c attached to the base end side. The front end of the bracket 7 has a pair of front axle supports 7d, 7d, and the front roller 8 is pivotally supported on the front axle su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com