Roofing system and method

A roof component and roof structure technology, applied to roofs, roof coverings, roofs using tiles/slate tiles, etc., can solve the problems of increasing the cost and weight of slate roofs, and achieve good protection, durable attachment, and easy repairs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

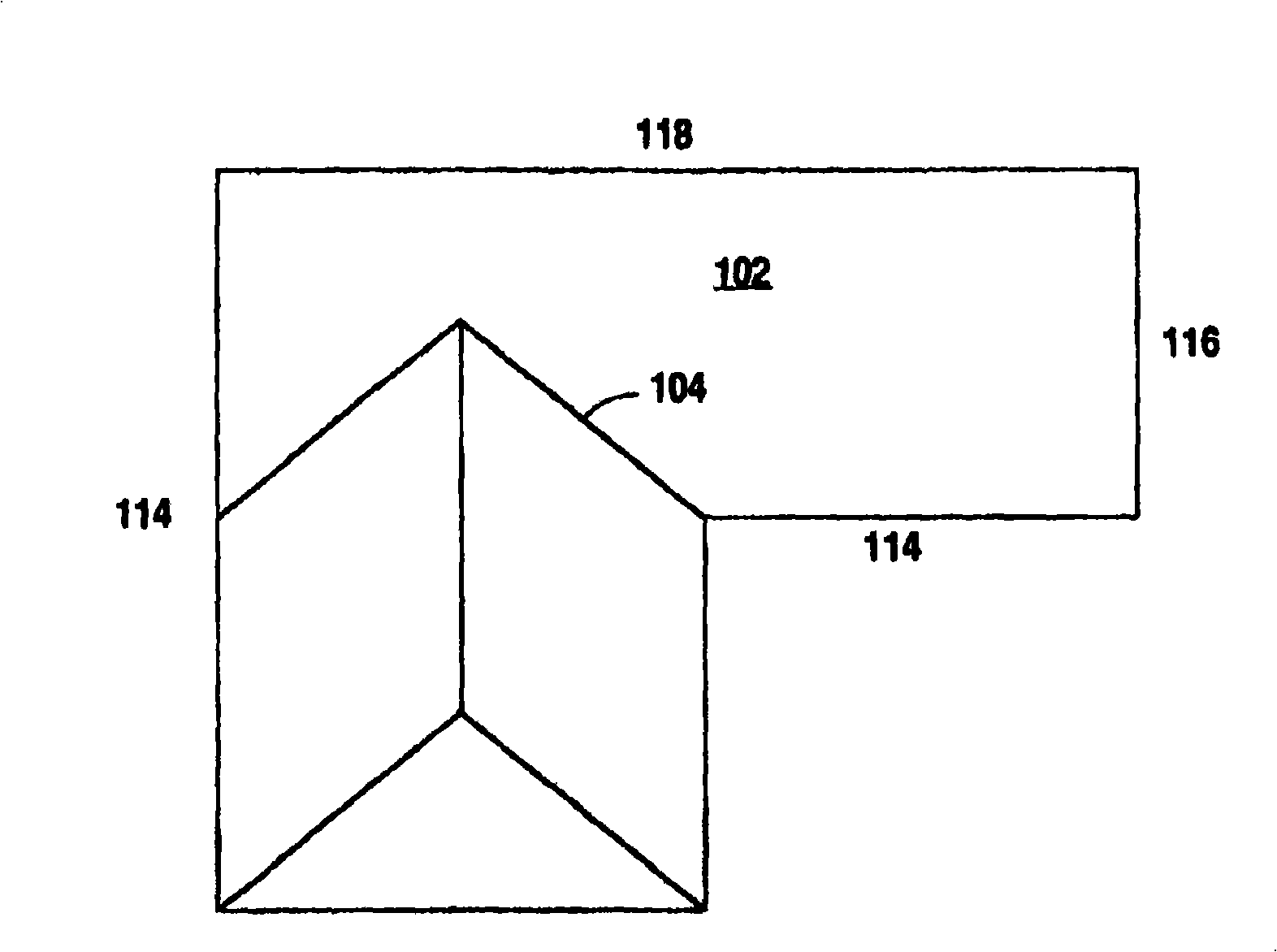

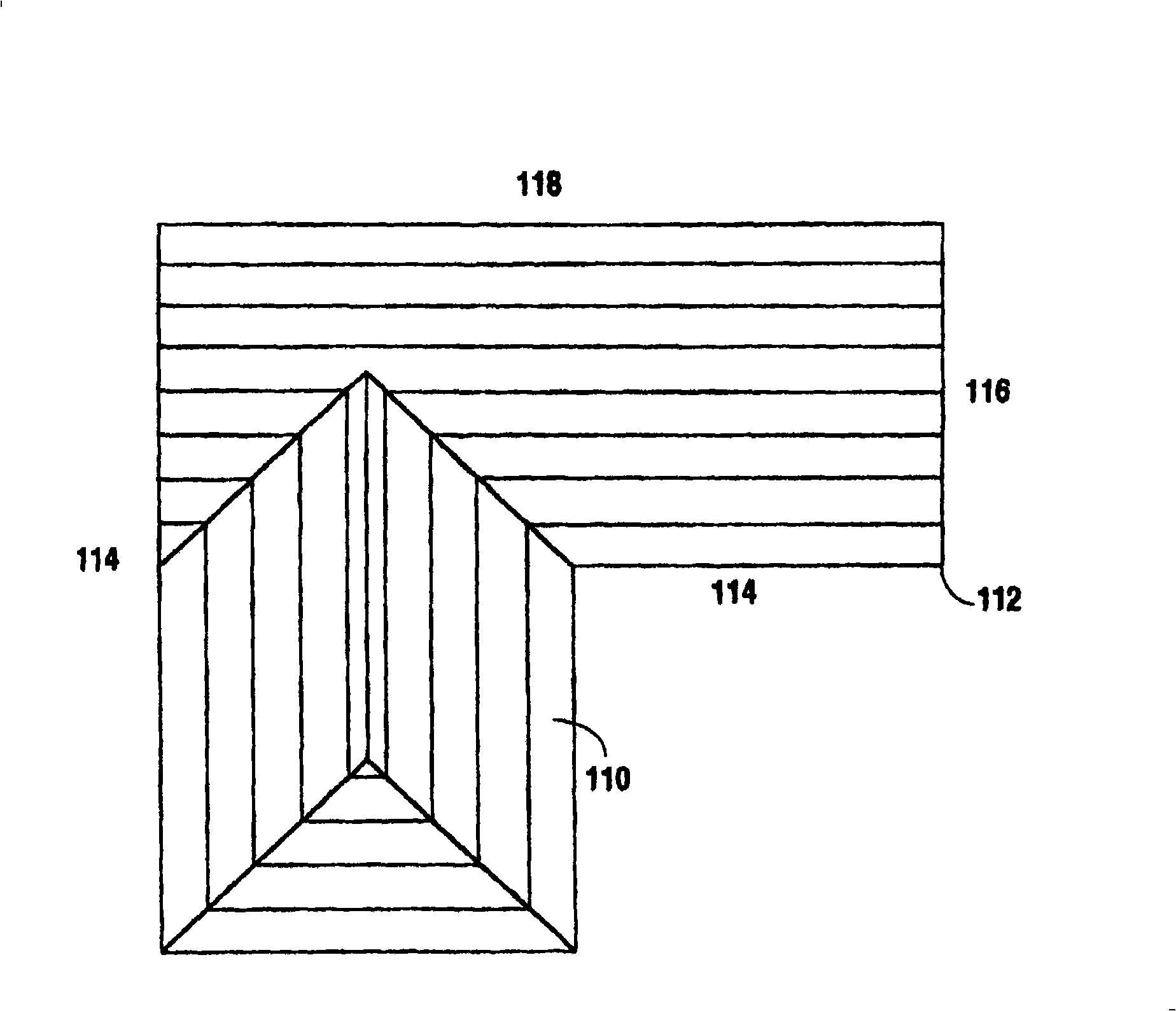

[0035] exist figure 1 In , a top view of a roof panel 102 is shown. In the method herein, an initial step is to inspect and prepare the shingle 102 . In one embodiment, roof panel 102 has gutters 104 , eaves 114 , gables / cornices 116 and ridge 118 . In this exemplary roof panel 102 inspection step, the existing roof sheathing is inspected for structural integrity. Roof panels 102 should preferably be a minimum of 15 / 32 inch plywood, or code approved oriented strand board (OSB). All shingle 102 nails should be driven flush with shingle 102 . Roof panels 102 should be inspected for protrusions that could damage felt backing 110 (see image 3 ).

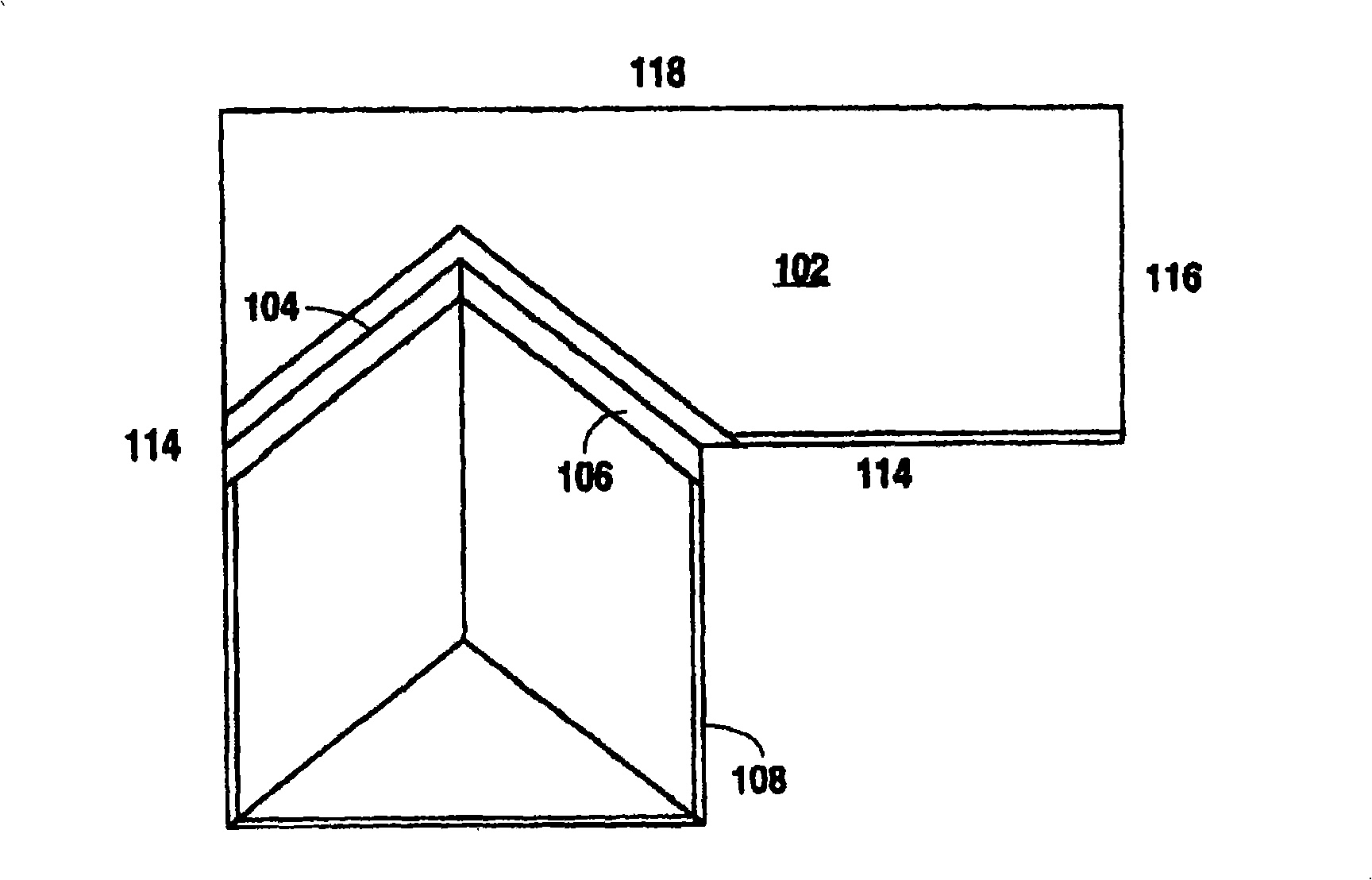

[0036] figure 2 is a top view of the shingle 102 illustrating the preparation of the gutter 104 and the installation of the drip gutter edge 108 . In this step of the method herein, the user installs a peel and stick membrane 106 in the gutter 104 while overlapping the seam of the membrane 106 with a preferred minimum of 6 inche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com