Planet cyclic gear train type polygonal rotor pump

An epicyclic gear train, polygonal technology, applied in the field of hydraulic pumps, can solve the problem of inability to adapt to high-speed operation, and achieve the effects of significant social benefits, increased rotational speed, and large displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

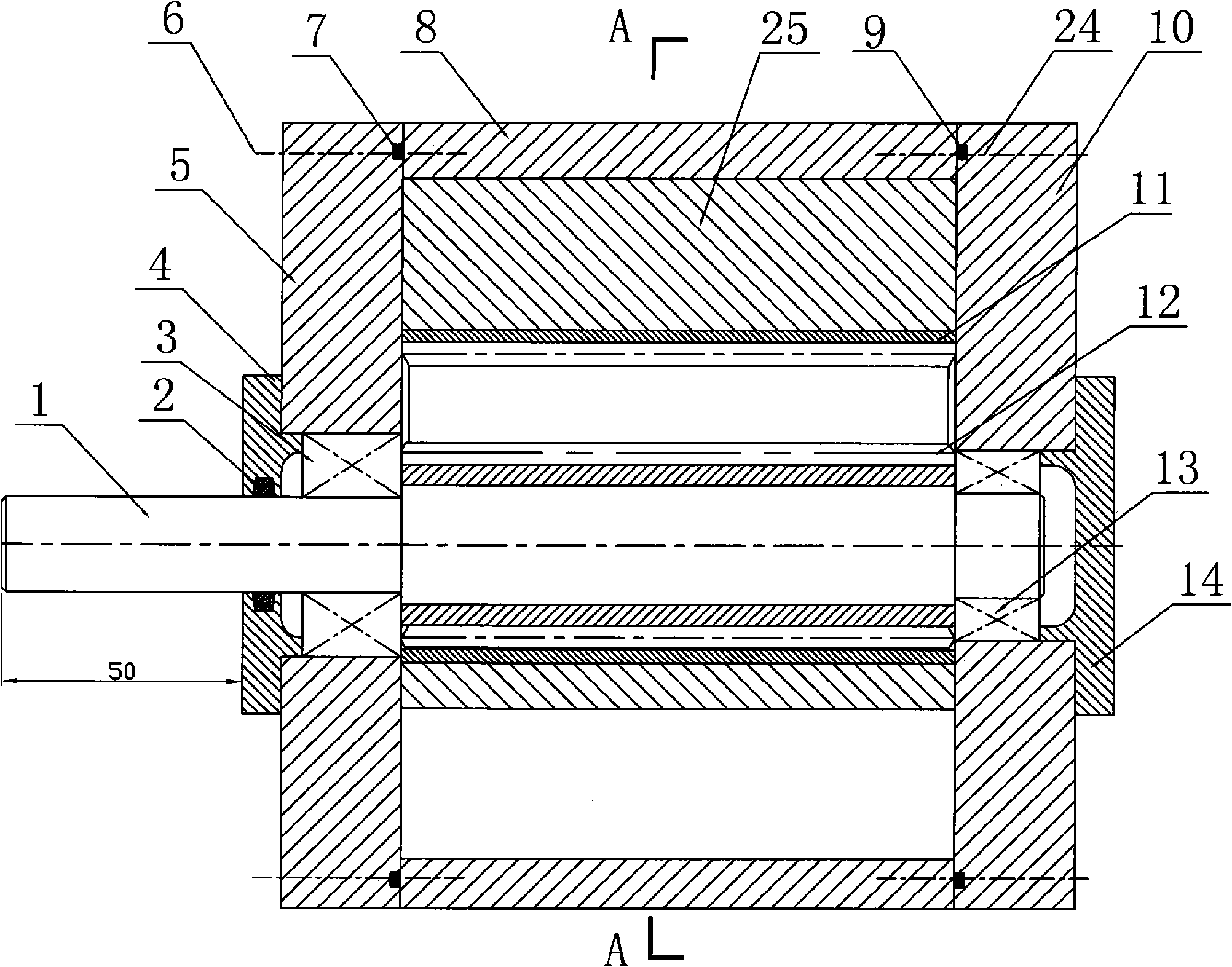

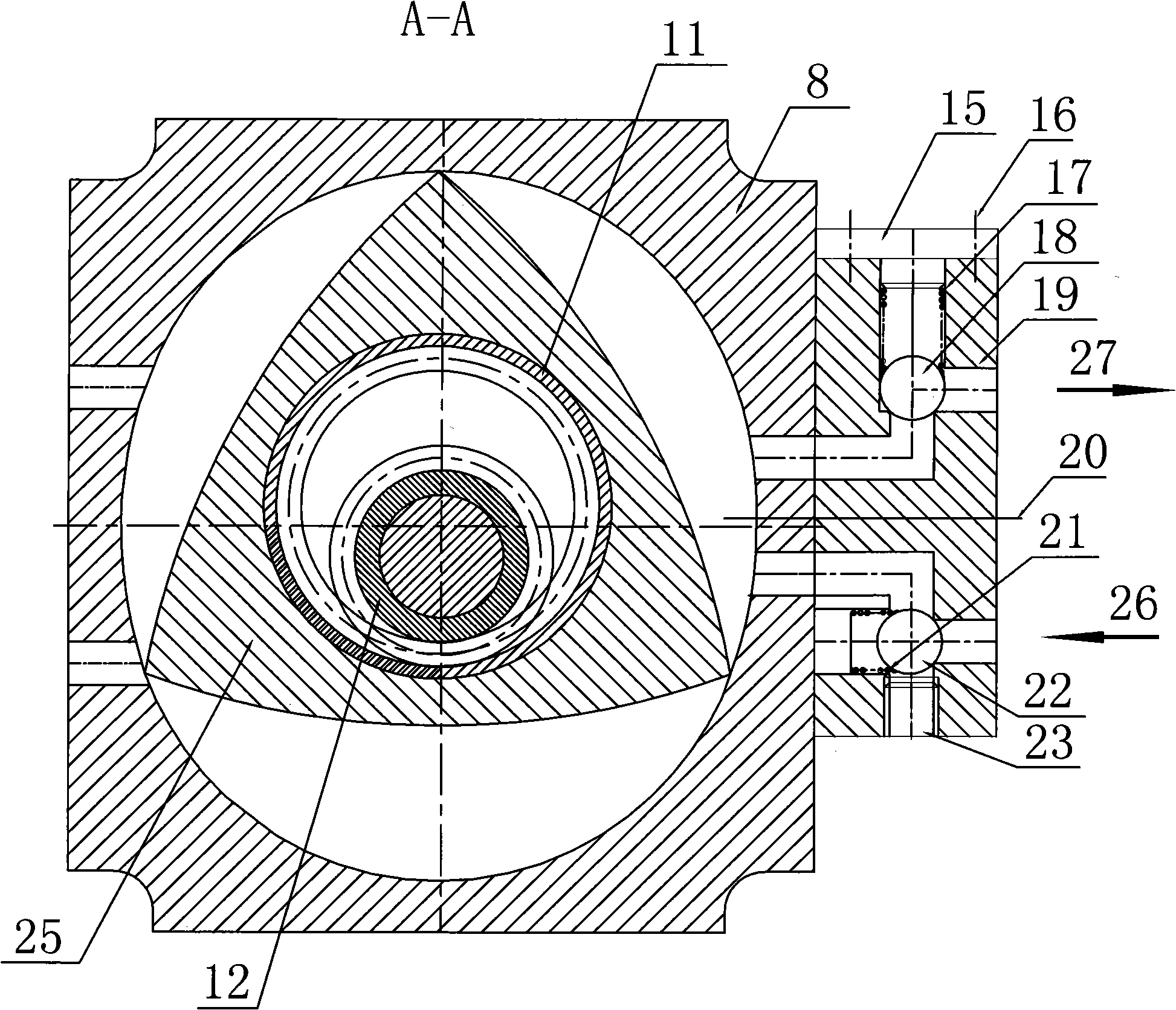

[0017] The specific embodiment of the present invention takes the triangular rotor pump as an example, as shown in the accompanying drawings: its structure is made up of pump body 8, suction and oil discharge device, inlet and outlet ports 26,27. There is an oil inlet 26 and an oil outlet 27 communicating with the body outside the body of the pump body 8; the suction and oil discharge device located in the pump body 8 is composed of a triangular rotor 25 and a planetary epicyclic gear train; the planetary epicyclic gear train is mounted on The body of the triangular rotor 25, and both ends of the rotor shaft 1 in the triangular rotor 25 are connected to the pump body 8 through sealing. The front end of the rotor shaft 1 is installed on the front cover 5 of the pump body 8 through the front bearing 3 , the bearing seal 2 and the front gland 4 fitted thereon. The rear end of the rotor shaft 1 is installed on the rear cover 10 of the pump body 8 through the rear bearing 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com