Push electric magnet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

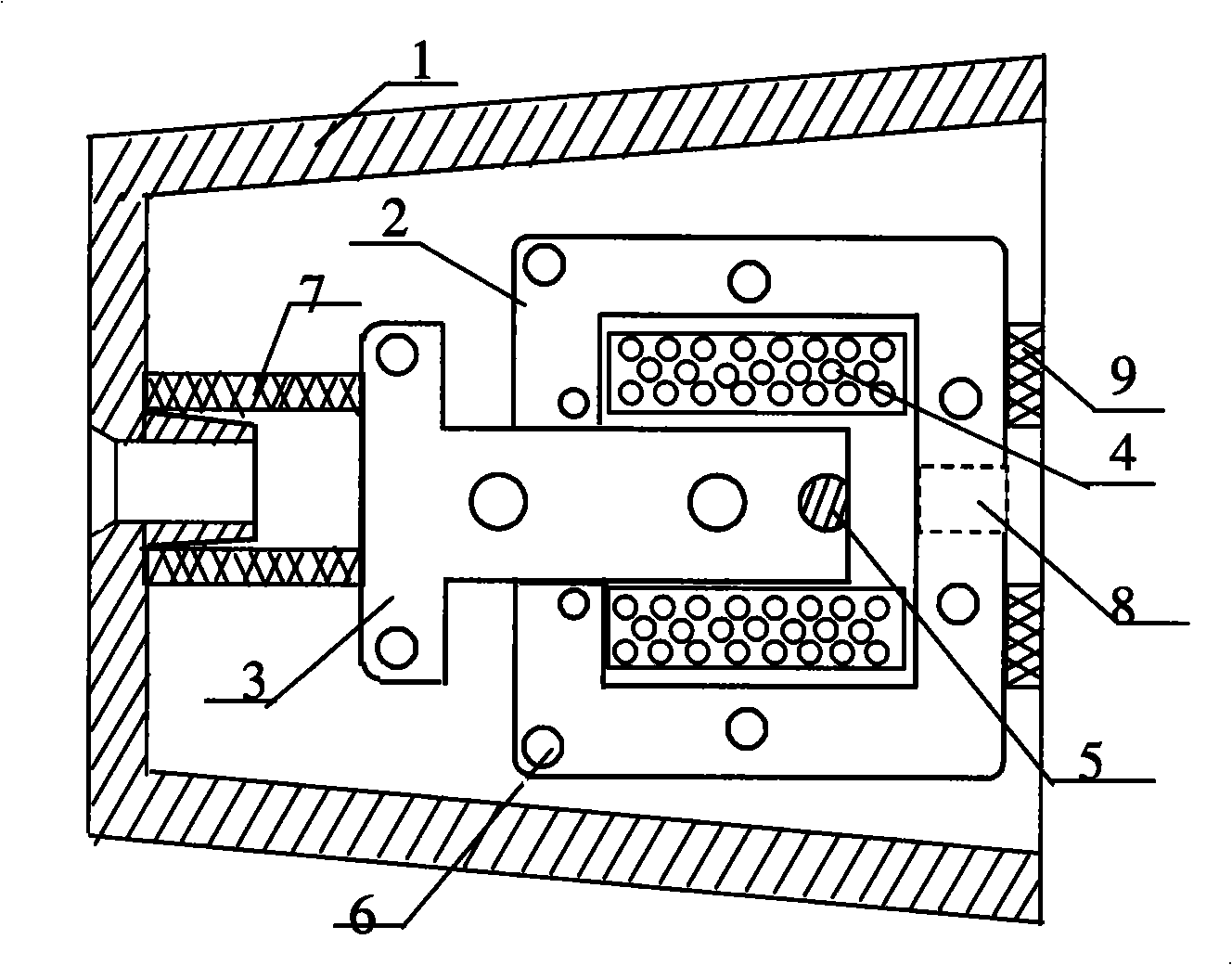

[0008] The implementation of the present invention will be described below in conjunction with the accompanying drawings. Depend on figure 1 It can be seen that the push electromagnet provided by the present invention is composed of an electromagnet housing 1, a static iron 2, a moving iron 3 and an electromagnetic coil 4, and a soft magnetic metal strip 5 is inlaid at the head end of the moving iron 3. When the electromagnetic coil 4 is energized, the strong magnetic field generated by the electromagnetic coil 4 and the static iron 2 surrounding the electromagnetic coil will attract the moving iron 3 into the space surrounded by the static iron 2 and the electromagnetic coil 4, and hit the rear part of the electromagnet for execution. The spring and push rod of the mechanism make the actuator complete the production work. Due to the effect of the soft magnetic metal strip 5 inlaid at the head end of the moving iron 3, the residual magnetism on the moving iron is very little ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com