Piezoelectric driving, harness-cord-free and returning-spring-free jacquard weave and needle selection mechanism

A piezoelectric driven, heddle spring technology, used in jacquard machines, textiles, textiles and paper making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

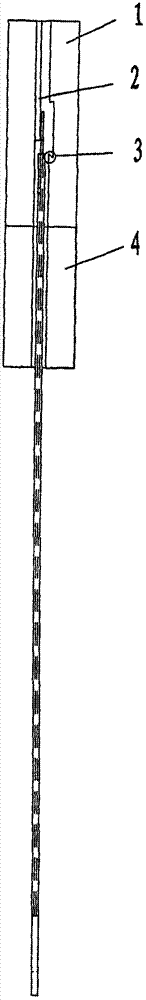

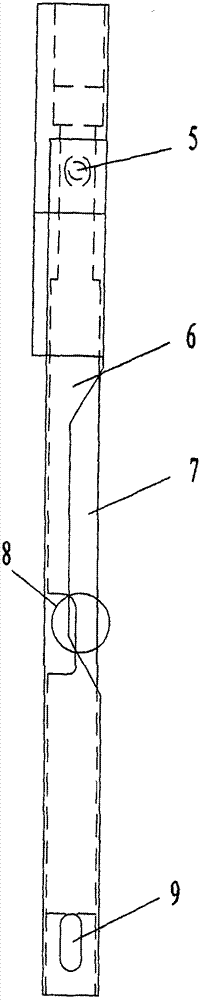

[0009] The present invention will be further described below with reference to the drawings; on the upper part of the guide rail 4 there is a piezoelectric drive chip mounting body 1. The piezoelectric drive chip 2 is attached to the piezoelectric drive chip mounting body. There is an outer lifting needle 6 in the chute of the guide rail, and an inner lifting needle 7 is installed in the outer lifting needle. The top of the inner lifting needle is in contact with the piezoelectric driving chip. There is a pin 5 on the upper part of the inner lifting needle. There is a heald frame heald rod penetration hole 9 at the bottom of the outer lifting needle. There is a pin hole on the upper part of the outer needle, and the pin is embedded in the pin hole. A hook 3 is provided on the mounting body of the piezoelectric drive chip. When working, the inner and outer needles form a heddle eye 8 when there is no relative movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com