Discharge lamp and backlight unit for backlighting a display device comprising such a discharge lamp

A technology of discharge lamps and discharge tubes, which is applied to the parts of gas discharge lamps, discharge lamps, electrical components, etc., and can solve the problems of reducing effective lumen output, large energy, and surface overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

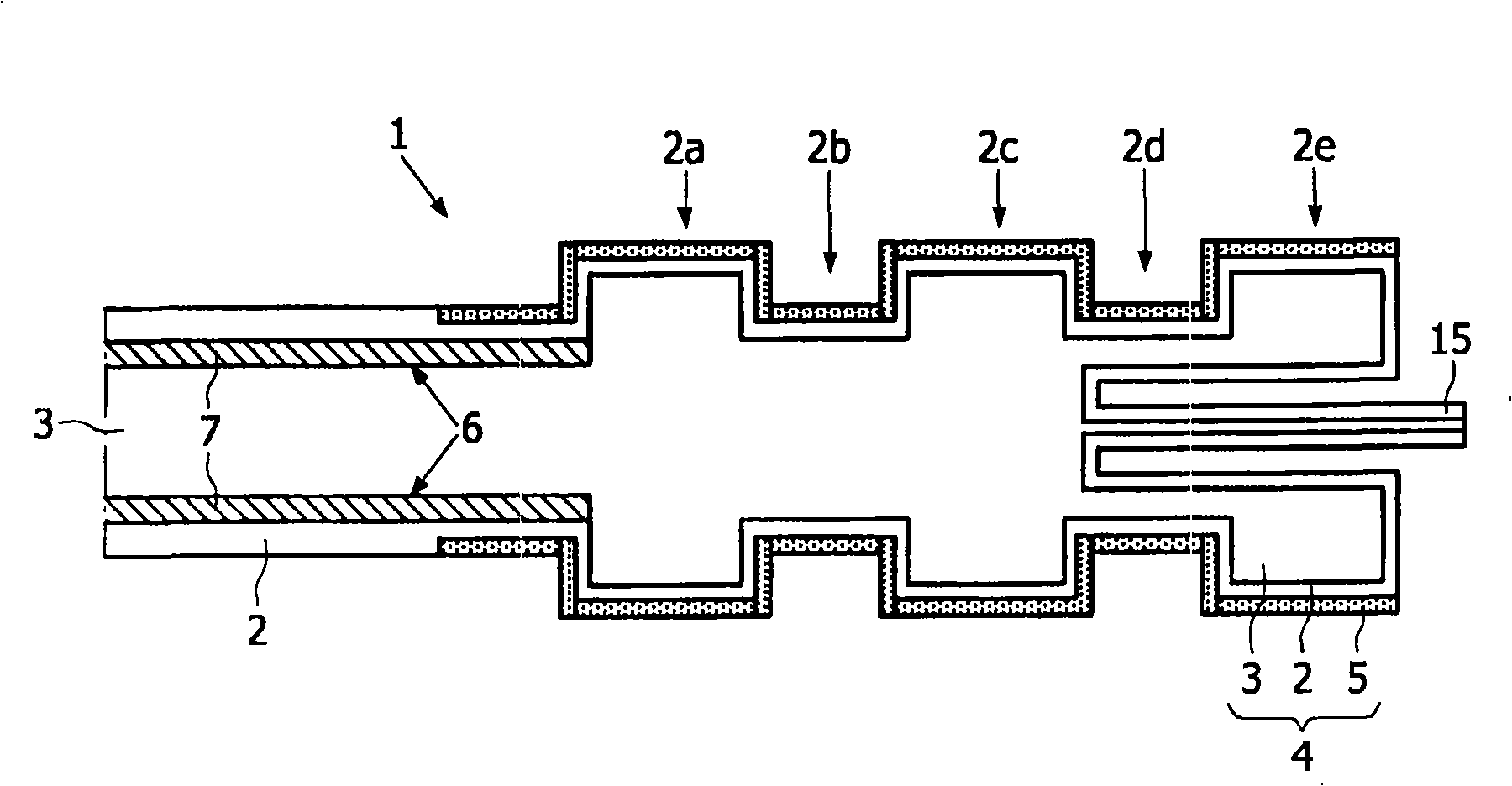

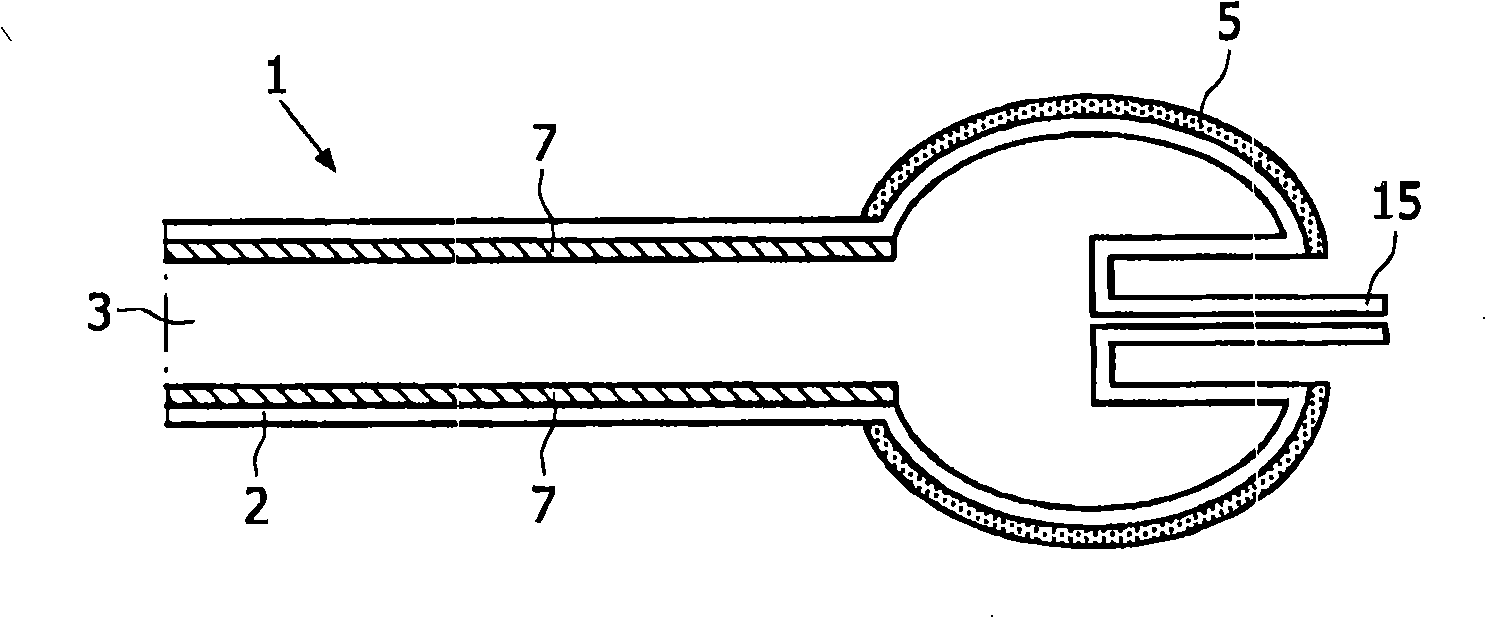

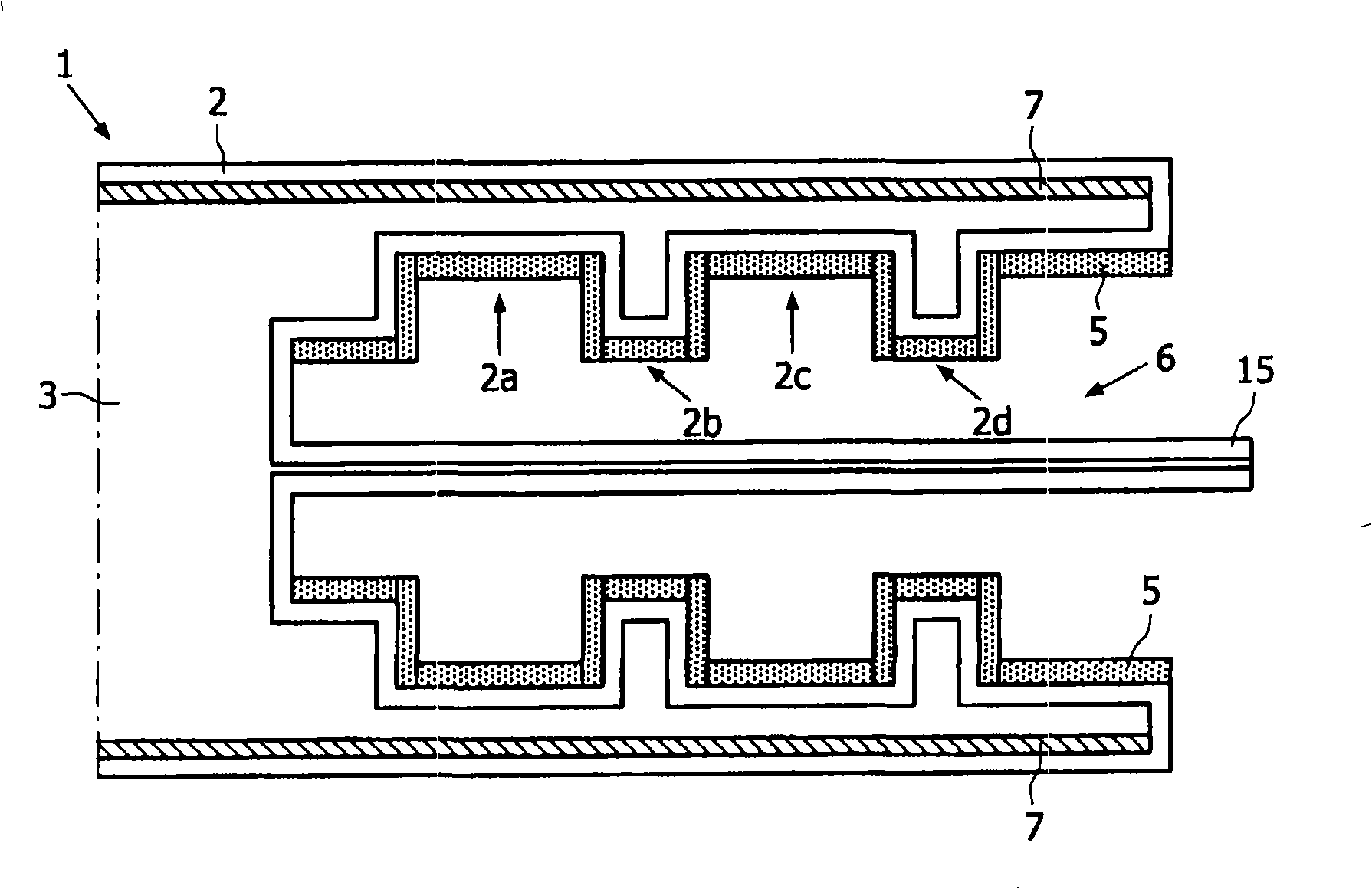

[0026] figure 1A side view showing part of a first embodiment of the fluorescent lamp of the present invention. The lamp 1 comprises an elongated substantially cylindrical discharge vessel made of glass and filled with an ionizable substance 3 such as a mixture of mercury and a noble gas. The discharge tube 2 is filled through an exhaust pipe 15 connected to the end surface of the discharge tube 2 . After filling the discharge vessel 2, the exhaust pipe 15 is sealed. At least two capacitive electrodes 4 (only one is shown in the figure) are connected to said tube 2, between which a discharge takes place during lamp operation along an axial distance. The axial direction is approximately parallel to the pipe wall 2 . The capacitive electrode 4 is adapted to capacitively couple HF electrical energy to said ionizable substance 3 . The capacitive electrode 4 is formed by a conductive layer 5 , such as metal, especially copper, so as to capacitively couple the tube wall 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com